Web Menu

Product Search

Language

Scroll

Jiangsu Top Intelligent Technology Co., Ltd.

Jiangsu Top Intelligent Technology Co., Ltd. (Wuxi Top Mixing Equipment Co., Ltd.) was established in 2003. It is a technology-based enterprise

specializing in mechanical mixing equipment and industrial intelligent control systems. Its products are mainly used in the fields of

pharmaceutical chemicals, biomass energy, energy storage batteries, fine chemicals, environmental protection, etc...

About Us-

0 +Industry

Experience(years) -

0 +Senior

Engineer(person) -

0 +Factory

Area(㎡) -

0 +Certificates

(patent)

We Provide

Jiangsu Top Intelligent Team has strong R&D capabilities and its

products are highly recognized by the industry.

-

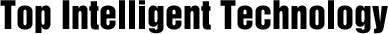

TOP62 Series DJH Homogenizer62 series DJH homogenous mixer is a product developed by our company in combination with advanced foreign technologies. It is suitable for the production of high-viscosity materials such as foundation, cream, and toothpaste. Its biggest feature is that the internal and external circulation homogenizer can enable the material to work in the internal and external circulation homogenization state so that the material can achieve a good emulsification effect. This homogeneous emulsion mixer is professionally designed according to the paste-making process of cosmetics and ointments. This unit consists of a pretreatment pot, vacuum emulsification mixing pot, vacuum pump, hydraulic system, material pouring system, electrical control system, working platform, and other parts. This unit is easy to operate, has stable performance, good homogeneous performance, high production efficiency, reasonable cleaning, small structure, low floor area, and a high degree of automation.Explore More

-

TOPH61 Series ZJH HomogenizerZJH homogenous mixer is a patented product developed by our company in combination with advanced foreign technologies and is complementary to the RHⅡ homogenous mixer. Suitable for the production of high-viscosity materials such as foundation, cream, and toothpaste. Its biggest feature is that the internal and external circulation homogenizer can enable the material to work in the internal and external circulation homogenization state so that the material can achieve a good emulsification effect. This homogenous mixer is professionally designed according to the paste-making process of cosmetics and ointments. This unit consists of a pretreatment pot, vacuum emulsification mixing pot, vacuum pump, hydraulic system, material pouring system, electrical control system, working platform, and other parts. This unit is simple to operate, has stable performance, good homogeneous performance, high production efficiency, convenient cleaning, reasonable structure, small footprint, and high automation.Explore More

-

TOPH53 Series SY Two-Speed Hydraulic MixerThe dual-speed multi-functional powerful dispersion mixer is a product with strong dispersion and stirring functions developed on the basis of a hydraulic lifting single-axis mixer. It has a concentric double-axis design; it has an extremely strong shearing effect and extremely high mixing efficiency; this product has good adaptability to medium and high viscosity and thixotropic materials, and a variety of stirring methods are available. Conventional such as anchor type, butterfly type, spiral type, frame type, etc., dispersion emulsification and stirring can be carried out simultaneously, driving the three-dimensional movement of edge materials and accelerating mixing. Wall scraping devices can also be installed to prevent the materials from sticking to the wall, which is highly adaptable and can be customized according to the characteristics of customers' materials and production process requirements.Explore More

-

TOPH52 Series SH Three-Shaft Double-Column MixerThe three-axle multi-function dual-column strong dispersion and mixing mixer is a product with strong dispersion and mixing functions developed on the basis of a hydraulic lifting single-axle mixer. The conventional form is a high-speed dispersion mixer combined with anchor-type wall scraping stirring, which has an extremely strong shearing effect and extremely high mixing efficiency. The product is very adaptable to medium-high viscosity and thixotropic materials; one of the sets of high-speed dispersers can replace medium-speed mixers, and the mixing methods are optional, such as screws, blades, frames, etc., and the good mixing form can be designed according to the characteristics of the material and production process.Explore More

-

TOPH52 Series SD Three-Axis Single Column MixerThe three-axle multi-function single-column strong dispersion and mixing mixer is a product with strong dispersion and mixing functions developed on the basis of a hydraulic lifting single-axle mixer. The conventional form is a high-speed dispersion mixer combined with anchor-type wall-scraping stirring, which has an extremely strong shearing effect and extremely high mixing efficiency. The product is very adaptable to medium-high viscosity and thixotropic materials; one of the sets of high-speed dispersers can replace medium-speed stirring, and the mixing methods are optional, such as screws, blades, frames, etc., and the good stirring form can be designed according to the characteristics of the material and production process.Explore More

-

TOPH51 Series FL High Speed DisperserThis series of dispersion mixers can be equipped with a toothed dispersion tray for high-speed dispersion stirring, or various types of stirring machines for stirring on various occasions. This series of mixers is usually used to stir, dissolve, and disperse liquid and liquid solid-phase materials in the chemical industry such as coatings, dyes, pigments, and adhesives.Explore More

-

TOPH42 Series US Twin Screw MixerThe 42 series US double screw mixer is manufactured and produced directly using American technology. Based on the data provided by users and the data collected in the experiment, American engineering, and technicians have developed this effective equipment to meet the different needs of users. Excellent production technology and high-quality materials ensure the long service life, and safe and reliable characteristics of the equipment. It is suitable for material mixing in different industries and is widely used in pharmaceuticals, food, fine chemicals, petrochemicals, pesticides, coatings, cosmetics, plastics, pigments, fees, and other industries.Explore More

-

TOPH41 Series U-Shaped Ribbon MixerThe working volume of the screw mixer is from 0.014m3-14.5m3. The different power and speeds meet more requirements. Its characteristic is that the equipment can be coordinated well with your machine. It has a vacuum and hot and cold jackets. The materials can be selected at any time. The intermediate or bottom discharge design is available. The cutter and a variety of filler boxes are available. Plus its unique four optional screw arrangement forms make the materials evenly mixed.Explore More

-

TOPH2032 Series SL Double Helix Conical MixerThe 32 series double helix conical mixer is a new type of mixing equipment with high homogeneity, low energy consumption, low residue, and low crushing. The equipment is equipped with two asymmetric spirals. While rotating around the axis, they rotate around the axis and use the rotation action of the rotating arm to make revolutions in the cone. The material is repeatedly lifted through the male and self-rotation of the spirals to finally achieve the purpose of mixing evenly. This product has a wide range of applications and can mix powder and powder, powder and liquid, and can stir fine powder, fiber, or sheet-like materials.Explore More

-

TOPH2031 Series V-Type Vacuum Ribbon MixerProduct Advantages 1. Frequently displace and stir the free-flow solid material. 2. Cantilever shaft structure, the bearing end does not come into contact with the material. 3. The gap between the stirring slurry and the container wall is very small to prevent the material from being bonded. 4. Standardized stirring drive box to ensure stable operation and low maintenance costs. 5. O-rings with special geometric shapes, high-quality equipment surface treatment and eliminate blind spots. 6. The container can be heated or cooled by an outer jacket (optional). 7. The crusher is used to prevent material from agglomerating.Explore More

-

TOPH2022 Series GG Industrial Planetary MixerThe 22 Series GG industrial planetary mixer is a new and efficient mixing equipment. The mixing paddle rotates around the axis of the kettle body while rotating around its own axis so that the materials can be fully mixed in the kettle; the 22 Series GG industrial planetary mixer has good mixing, stirring, reaction, dispersion ,and dissolution, and is especially suitable for solid-solid and solid-liquid mixing. At the same time, the equipment also has a wall scraping function, which ensures no dead corners and no residues during the entire equipment operation. There are many forms of stirring paddles, and the contact material part can be sprayed with ceramic materials (zirconia/tungsten carbide/Teflon, etc.). Reduces metal ion pollution.Explore More

-

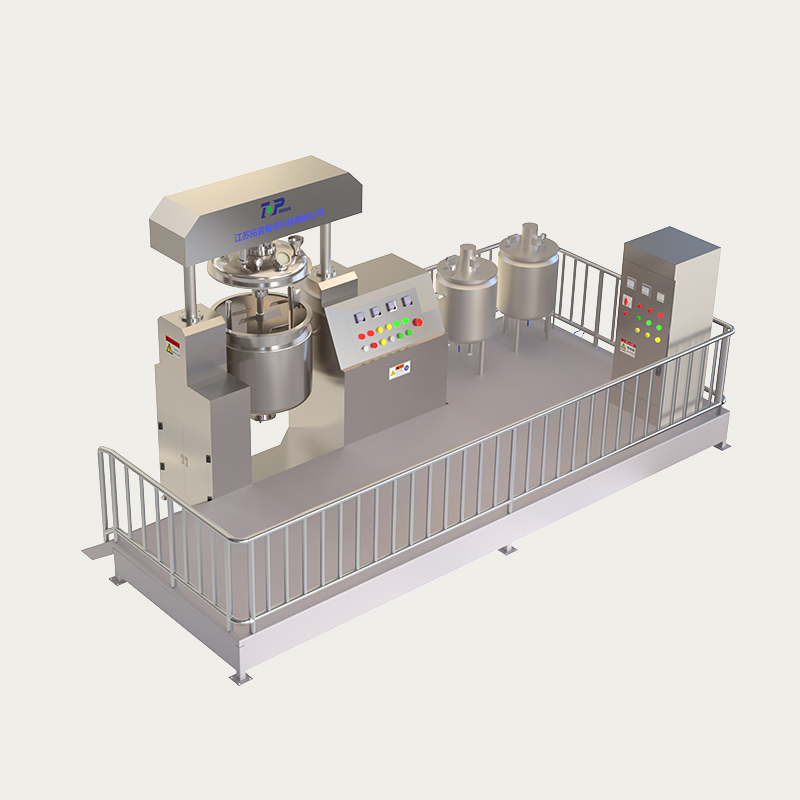

TOPH2021 Series ZG Pilot Planetary MixerDuring the working process of the 21 series ZG type pilot planetary mixer, two parallel mixing pads operate in a fixed rotation ratio set, and rotate quickly along the mixing drum. At the same time, there is a rotating scraper that operates simultaneously with the revolution in the mixing drum, which keeps rotating, so that the material moves from the inner wall of the mixing drum to the vicinity of the mixing pad. The direction of the mixer can be reversible in the same direction and reversible in order to achieve different shearing purposes. The other two high-speed dispersed gear discs of separate power units also operate along the mixing barrel along with the rotation, performing efficient dispersion, emulsification, and high-speed dispersed gear discs to be variable frequency speed regulation, and can be customized according to the production process. This type of movement can enable the material to achieve a completely uniform emulsification and mixing effect in a short time and is especially suitable for the dispersion and mixing of solid-solid phase, solid-liquid phase, and liquid-liquid phase.Explore More

Top Intelligent Tech

Jiangsu Top Intelligent Technology Co., Ltd. has introduced European

technology and advanced testing equipment through cooperation with TOP

MIXER PTE. LTD. The company has a number of patents to solve mixing

problems. Through ERP and 5S management, it has obtained ISO9001

certification, provides high-quality products, and cooperates with

well-known companies.

-

Advanced Technology

Advanced Technology -

Testing Capabilities

Testing Capabilities -

Research and Innovation

Research and Innovation -

High-Quality Management

High-Quality Management

Innovative Mixing and Control

Solutions Across Industries

We provide advanced mechanical mixing and intelligent control technologies across various industries, enabling our clients to achieve exceptional process efficiency and product quality.

View All

News&Blog

View All News-

Jan.04.2026Introduction to High Temperature Stirring SystemHigh-temperature mixing systems are devices used to mix materials in high-temperature environments, and are widely used in industries such as chemical, pharmaceutical, metallurgical, glass, and food processing. Our company provides design and manufacturing services for mixing processes above 400°C, requiring reliable mechanical seal technology to handle process temperatures from 500°C to 750°C. High-temperature mixing systems are devices used to mix materials in high-temperature environments, and are widely used in industries such as chemical, pharmaceutical, metallurgical, glass, and food processing. Our company provides design and manufacturing services for mixing processes above 400°C, requiring reliable mechanical seal technology to handle process temperatures from 500°C to 750°C. 1. Composition and Structure Agitation device: This includes components such as agitator, agitator shaft, and drive motor. The shape and size of the agitator are designed according to the properties of the material and agitation requirements, such as turbine type, spiral type, and paddle type. Heating system: Used to provide a high-temperature environment, common heating methods include electric heating, steam heating, and oil bath heating. The heating system requires precise temperature control to meet process requirements. Sealing systems: These prevent the leakage of high-temperature materials. Common sealing methods include mechanical seals and magnetic seals. Mechanical seals are suitable for high-temperature and high-pressure environments, while magnetic seals transmit power through a magnetic field to prevent leakage. Control system: Includes temperature controller, speed controller, motor driver, etc., used to achieve precise control of stirring speed and temperature. Modern high-temperature stirring systems are usually equipped with PLC or touch screen operating interface to achieve automated control. Auxiliary systems include cooling systems and nitrogen protection systems. Cooling systems reduce the temperature of the stirring shaft and motor to prevent overheating damage; nitrogen protection systems prevent material oxidation or combustion. 2. Technical Features High temperature resistance: The system materials must have good high temperature resistance, such as using high temperature resistant alloys, ceramics and other materials, to ensure stable operation in high temperature environments. Sealing performance: Advanced sealing technologies, such as liquid lubricated mechanical seals and magnetic coupling seals, are used to prevent leakage of high-temperature materials and ensure operational safety. Precise control: The PID control algorithm enables precise control of temperature and stirring speed, ensuring uniform mixing of materials and stable reaction conditions. Energy efficient: Optimize heating and cooling systems to reduce energy loss and improve energy utilization efficiency. Safe and reliable: Equipped with multiple safety protection devices, such as overheat protection, overload protection, and leakage alarm, to ensure safe operation of the equipment. 3. Application Scenarios Chemical industry: Used in high-temperature polymerization reactions, esterification reactions, etc., to ensure that reactants are fully mixed and improve reaction efficiency. In the pharmaceutical industry, during processes such as high-temperature sterilization and drug synthesis, it is essential to ensure uniform mixing of materials to avoid localized overheating or incomplete reactions. In the metallurgical industry, such as high-temperature smelting and metal extraction, stirring promotes the separation of metal and slag, thereby increasing the metal recovery rate. In the glass industry, stirring helps to remove air bubbles from the glass during the glass melting process, making the glass melt more uniform and improving product quality. Food processing: such as high-temperature sterilization of sauces and chocolate refining, to ensure that food maintains its quality and taste during high-temperature processing. 4. Strengths and Challenges Advantages: Improve material mixing efficiency and ensure uniformity in reaction or processing. Precise control of temperature and stirring speed meets different process requirements. An efficient sealing and cooling system ensures safe operation of the equipment. challenge: High-temperature environments require materials with high durability and stability, which increases equipment costs. The reliability of the sealing system is crucial, as leaks can lead to safety incidents. The design and maintenance of high-temperature stirring systems require professional technical support.Explore More

-

Jan.04.2026Introduction to High-Shear EmulsifiersA high-shear emulsifier is an industrial device that uses high shear force generated by mechanical action to mix, emulsify, disperse, and homogenize immiscible liquid, solid, and gaseous materials. It is widely used in the food, chemical, pharmaceutical, and cosmetic industries, efficiently refining and uniformly distributing materials to form stable emulsions or suspensions. A high-shear emulsifier is an industrial device that uses high shear force generated by mechanical action to mix, emulsify, disperse, and homogenize immiscible liquid, solid, and gaseous materials. It is widely used in the food, chemical, pharmaceutical, and cosmetic industries, efficiently refining and uniformly distributing materials to form stable emulsions or suspensions. 1. Working principle The core components of a high-shear emulsifier are the rotor and stator. Its working process is as follows: Material suction: The high-speed rotating rotor generates a strong centrifugal force, which sucks the material from the feed area of the working head into the working chamber. Primary emulsification: Under the action of centrifugal force, the material is thrown into the narrow gap between the stator and the rotor, and is subjected to centrifugal compression, shearing and other forces, thus initially achieving dispersion and emulsification. Extrusion: The linear velocity at the outer end of the rotor is very high (up to 15 m/s or more, and up to 40 m/s). The material is further refined under the action of strong shearing force and extruded from around the stator slots. Circulating emulsification: The extruded material changes its flow direction due to the resistance of the inner wall of the container, forming two strong turbulent flows. After multiple cycles, the material is finally dispersed, emulsified and homogenized. 2. Technical Features High-efficiency shearing: The high-speed relative motion between the rotor and stator generates a strong shearing force, which can rapidly reduce the droplet size and achieve efficient emulsification and dispersion. Multi-material processing: Suitable for mixing and emulsifying various materials such as liquid-liquid, liquid-solid, and gas-liquid, and also has good processing effect on high viscosity and high concentration materials. Compact structure: The equipment has a compact structure, is easy to install, operate and maintain. Multiple configurations: Models with different power, speed and installation methods are available to meet different production scales and process requirements. Material selection: Parts that come into contact with materials are usually made of corrosion-resistant materials such as 304 or 316L stainless steel to ensure the durability of the equipment and the hygiene and safety of the materials. 3. Application Areas Food industry: Used in the production of dairy products, beverages, seasonings, etc., to improve product stability and taste. Chemical industry: Used in the production of coatings, adhesives, fine chemicals, etc., enabling uniform mixing and dispersion of materials. Pharmaceutical industry: Used in the preparation of ointments, emulsions, suspensions, etc., to ensure the uniform distribution of drug components. In the cosmetics industry: it is used to produce lotions, creams, serums, etc., and can improve the stability and effectiveness of the products. High-shear emulsifiers, with their high efficiency, flexibility and reliability, have become an indispensable piece of equipment in modern industrial production, significantly improving production efficiency and product quality.Explore More

-

Jan.04.2026Introduction to Magnetic StirrersA magnetic top-feed stirrer is a stirring device that mounts a magnetic stirring arm on top of a container. It is widely used in laboratories and industrial production. The following is a brief introduction to magnetic top-feed stirrers, including their working principle, technical features, and application scenarios. Introduction to Magnetic Stirrers A magnetic top-feed stirrer is a stirring device that mounts a magnetic stirring arm on top of a container. It is widely used in laboratories and industrial production. The following is a brief introduction to magnetic top-feed stirrers, including their working principle, technical features, and application scenarios. 1. Working principle The working principle of a magnetic top-feed stirrer is based on magnetic coupling. Its core components include: External magnetic rotor: driven by a motor to rotate, generating a rotating magnetic field. Internal magnetic rotor (stirring): Placed in the liquid inside the container, it rotates under the influence of the magnetic field of the external magnetic rotor. Isolation sleeve: Separates the outer magnetic rotor from the inner magnetic rotor to prevent liquid leakage, while protecting the motor and magnetic system. When the motor drives the outer magnetic rotor to rotate, the rotating magnetic field generated by the outer magnetic rotor penetrates the isolation sleeve and acts on the inner magnetic rotor, causing it to rotate synchronously. The rotation of the inner magnetic rotor drives the liquid to form eddies, thereby achieving uniform stirring of the liquid. 2. Technical Features Non-contact transmission: Non-contact transmission is achieved through magnetic coupling, avoiding the shaft seal leakage problem of traditional mechanical agitators, and is particularly suitable for handling corrosive or high-purity liquids. Excellent sealing performance: Since the inner and outer magnetic rotors are completely isolated by the isolation sleeve, the liquid will not leak during the stirring process, ensuring high safety. Easy to install: The stirring device is installed on top of the container, making it easy to install and remove, and simple to maintain. Wide range of applications: It can handle liquids of different viscosities, and different shapes and sizes of stir bar can be selected as needed. Low shear force: Suitable for samples that are sensitive to shear force, such as cell cultures and suspensions. Energy-saving and efficient: Magnetic coupling transmission has high efficiency and low energy consumption. 3. Application Scenarios Laboratory: Used for experimental operations such as solution mixing, dissolution, and chemical reactions, especially suitable for experiments with high requirements for sterility and pollution-free conditions. Industrial production: Used in industries such as chemical, pharmaceutical, and food processing for stirring high-viscosity liquids and mixing materials in reaction vessels. Biopharmaceuticals: Used in bioreactors for processes such as cell culture and bio-fermentation, ensuring aseptic operation. 4. Strengths and Challenges Advantages: No leakage risk: Magnetic coupling avoids the leakage problem of mechanical seals and improves safety. Easy to operate: easy to install and use, and low maintenance cost. High applicability: Suitable for a variety of liquids and process conditions. challenge: Challenges in scaling up: For large containers, the manufacture and installation of magnetic stirrers are quite difficult, and the strength and stability requirements for the stirring shaft are high. Limited stirring effect for high-viscosity liquids: When handling extremely high-viscosity liquids, the stirring efficiency may be lower than that of mechanical stirrers. Magnetic top-load stirrers, with their unique non-contact transmission method and efficient and safe stirring performance, have become indispensable equipment in modern laboratories and industrial production. Introduction to Magnetic Bottom Stirring A magnetic bottom-entry mixer is a mixing device that uses magnetic drive technology. Its mixing unit is located at the bottom of the container, and the stirring paddle is rotated through non-contact magnetic coupling transmission to achieve uniform mixing of liquids. The following is a detailed introduction to magnetic bottom-entry mixers: 1. Working principle Magnetic bottom-entry mixers utilize the principle of attraction between opposite poles and repulsion between like poles in magnetic materials. An external magnetic drive device generates a rotating magnetic field, which in turn drives the internal stirring paddle (or stirrer) to rotate. Its working process is as follows: An external magnetic drive device (such as a magnet driven by an electric motor) generates a rotating magnetic field. The internal stirring paddle (or stirrer) rotates synchronously with the external magnetic field through magnetic coupling. The rotation of the stirring paddle causes the liquid inside the container to form a vortex, thereby achieving uniform mixing of the liquid. 2. Technical Features No leakage risk: Magnetic coupling drive eliminates the need for mechanical seals, avoiding the leakage problems of traditional mechanical seals. It is especially suitable for handling toxic, harmful, flammable, explosive or high-purity materials. High cleanliness: The stirring device is located at the bottom of the container, reducing dead zones and ensuring uniform mixing of materials, making it suitable for applications with high cleanliness requirements. Long life design: High-performance magnets and corrosion-resistant materials, such as 316L stainless steel, extend the service life of the equipment. Safe and reliable: By replacing the dynamic mechanical seal with a static seal using a welded isolation sleeve, the problems of running, leaking, dripping, and seeping from traditional seals are solved. Highly efficient mixing: The bottom-mounted agitator generates good circulation flow, improving mixing efficiency. 3. Application Scenarios Magnetic bottom-entry mixers are widely used in the following fields: Pharmaceutical industry: Used in mixing, reaction and other processes in drug production to meet GMP standards. Biotechnology: Ensuring aseptic operation in processes such as bio-fermentation and cell culture. Food and beverage industry: Used for stirring and mixing in food processing to ensure product quality and safety. Chemical industry: Used for mixing and reactions in the production of fine chemicals. 4. Strengths and Challenges Advantages: No risk of leakage, high safety. It has high cleanliness and is suitable for industries with high hygiene requirements. Long lifespan design reduces maintenance costs. challenge: For high-viscosity materials, mixing efficiency may not be as good as that of mechanical agitators. The equipment cost is relatively high. Magnetic bottom-entry mixers, with their unique features of being leak-free, highly clean, and having a long service life, play an important role in industries such as pharmaceuticals, biotechnology, food, and chemicals, and are one of the indispensable pieces of equipment in modern industrial production.Explore More

-

Nov.01.2024The application prospects of new nanomaterials in mixing equipment are broadWith the advancement of nanotechnology, the application of nanomaterials in mixing equipment manufacturing is becoming a new trend in the industry. The Massachusetts Institute of Technology research team has recently developed a graphene-based nano-coating material that can significantly improve the wear and corrosion resistance of mixing equipment, and the service life can be increased by more than 50%. In addition, the nano-ceramic material developed by the Fraunhofer Institute in Germany can also be used to manufacture high-strength and lightweight mixing blades, which is expected to improve the performance of mixing equipment greatly. Industry experts predict that nanomaterials have broad application prospects in the field of mixing equipment and are expected to bring new growth points to the industry.Explore More

-

Nov.01.2024Environmentally friendly mixing equipment is favored by the marketWith the improvement of global environmental awareness, energy-saving, and environmentally friendly mixing equipment is being favored by more and more customers. The new airflow mixing technology developed by Satake of Japan can reduce the energy consumption required for mixing by more than 50%, and greatly reduce the escape of dust, achieving significant energy-saving and emission reduction effects. The new variable frequency motor agitator launched by Chemineer in the United States can optimize energy consumption according to working conditions by adjusting the speed in real-time, with an energy-saving effect of more than 30%. More and more Chinese companies have also joined the research and development and production of environmentally friendly mixing equipment, and have made positive progress.Explore More

-

Nov.01.2024Intelligent mixing equipment has become a new direction for industry developmentUnder the background of Industry 4.0 and intelligent manufacturing, mixing equipment manufacturers are accelerating their development towards intelligence. The intelligent mixing control system developed by Siemens of Germany can realize real-time monitoring, fault warning, and adaptive optimization of the mixing process by integrating cutting-edge technologies such as the Internet of Things and machine learning, and production efficiency can be increased by more than 30%. Sulzer of Switzerland has also launched a remote operation and maintenance service based on a cloud platform, and customers can remotely monitor and control mixing equipment through mobile terminals. Industry insiders said that intelligence has become the only way for the mixing equipment industry, and more companies will invest in the research and development and application of related technologies in the future.Explore More

- No. 118, Chuangye Road, Jieshou Town, Gaoyou City, Yangzhou, Jiangsu Province, China

- [email protected]

- Landline: +86-0510-83383966 +86-0510-83390667

- Mr. Chen: +86-18061519769 Mr. Xu: +86-13706183972

- Mr. Li: +86-18915358212 Mr. Lu: +86-18915337056

- Product Link

- Top-Entry Mixer

- Bottom-Entry Mixer

- Side-Entry Mixer

- SIGN UP

- Sign up to be the first to find out the latest news from Top Intelligent Technology

- Subscribe

Copyright © WUXI TOP MIXER EQUIPMENT CO., LTD.

English

English