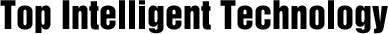

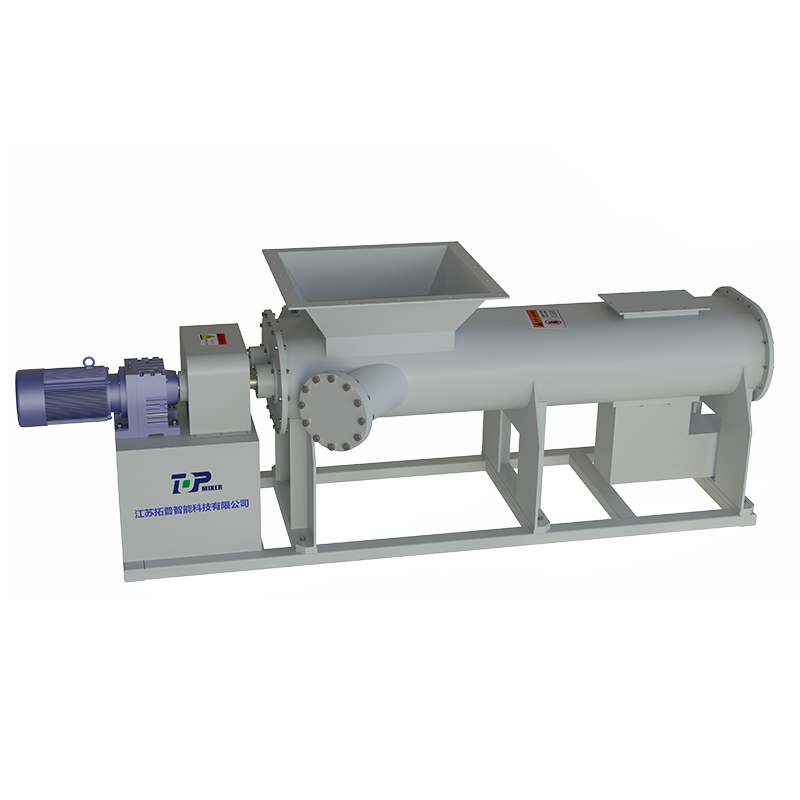

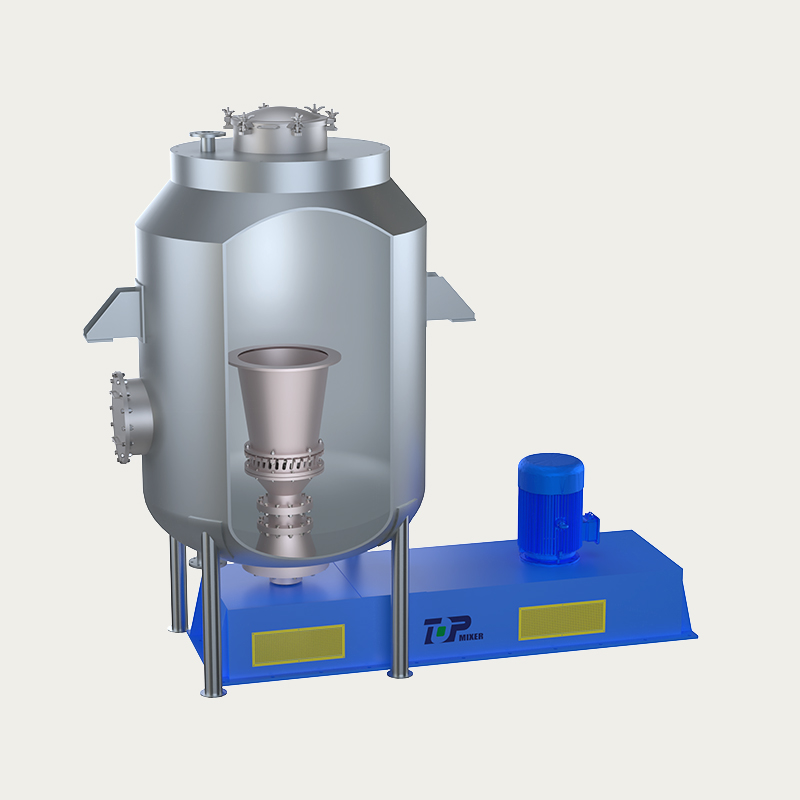

TOPH42 Series US Twin Screw Mixer

The 42 series US double screw mixer is manufactured and produced directly using American technology. Based on the data provided by users and the data collected in the experiment, American engineering, and technicians have developed this effective equipment to meet the different needs of users. Excellent production technology and high-quality materials ensure the long service life, and safe and reliable characteristics of the equipment. It is suitable for material mixing in different industries and is widely used in pharmaceuticals, food, fine chemicals, petrochemicals, pesticides, coatings, cosmetics, plastics, pigments, fees, and other industries.

Features

1. Wide scope of application. It is possible to mix powder and powder, powder and liquid. It can also be used as reaction equipment and drying equipment.

2. Good mixing uniformity. It can make evenly mixed materials with a ratio of 1:10,000, especially for materials with different specific gravity.

3. Its advantages.

4. The mixing process is mild and has little crushing ability.

5. After special design, the equipment meets the requirements of GMP standards.

6. The mixing speed is fast and the efficiency is high.

7. Large load factor and small energy consumption.

8. The discharge is fast and convenient. Usually, a batch of materials is released in 2 to 5 minutes.

9. The equipment runs smoothly and reliably, has few consumable parts, has a long service life, is convenient to maintain, and is easy to operate.

Product Features

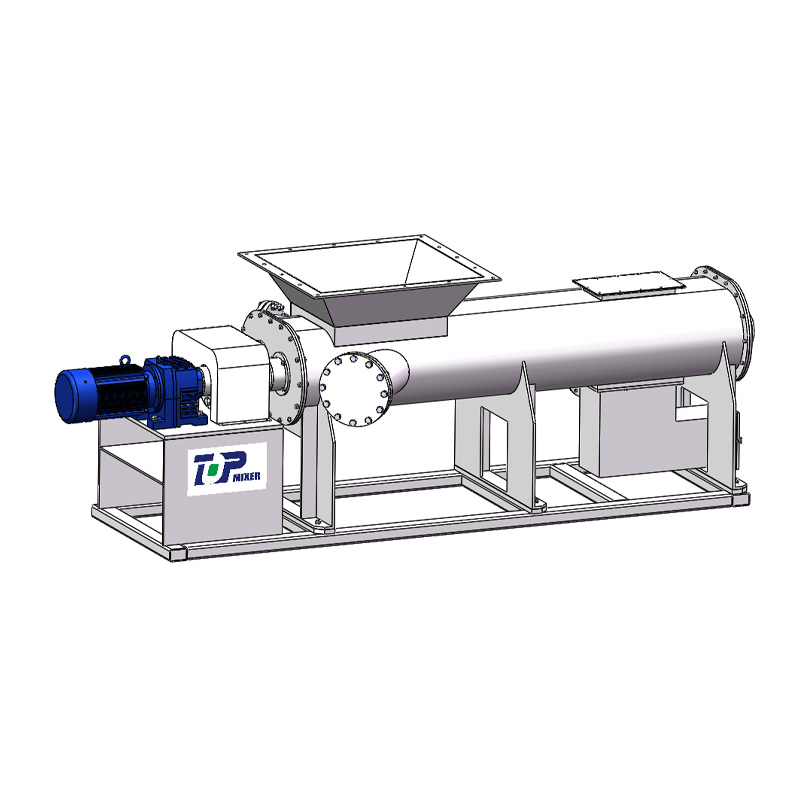

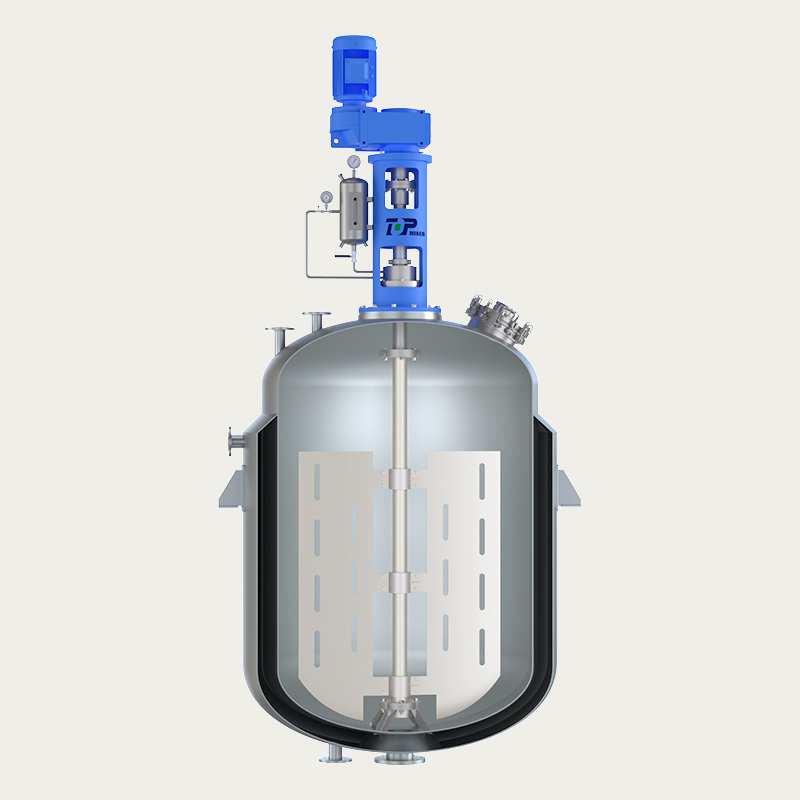

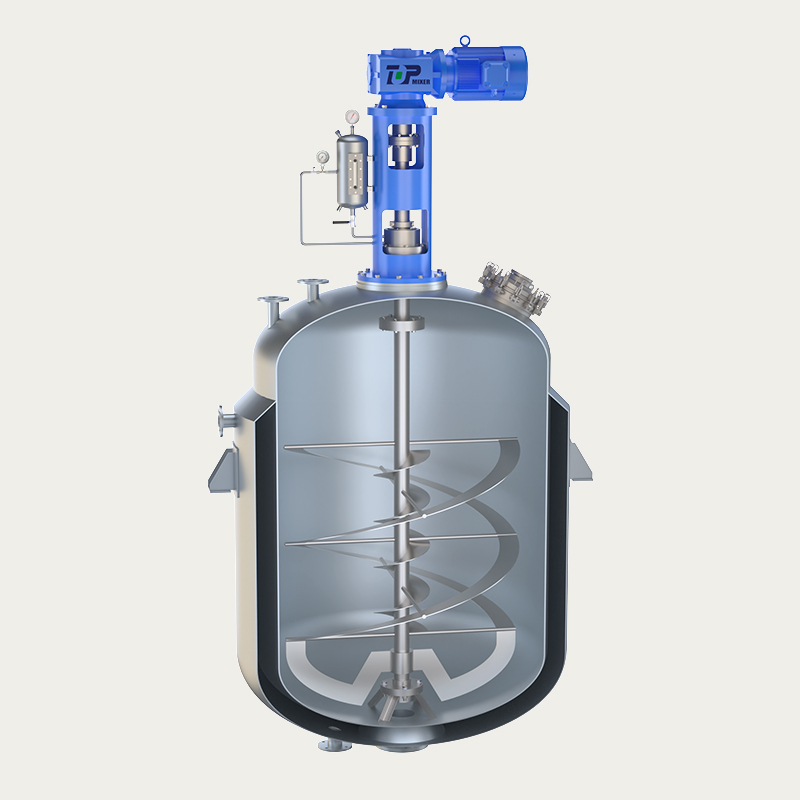

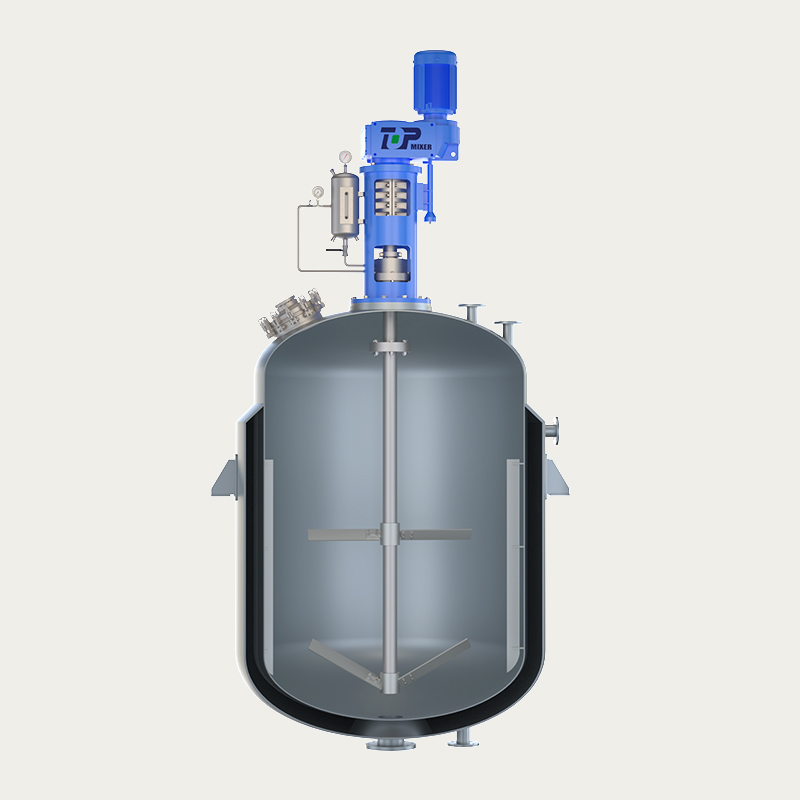

Cylinder form------Two forms are available

U-shaped cylinder: a commonly used form, with a large mixing capacity, easy to clean

Round cylinder: a commonly used form in a vacuum or pressure state. When using hot and cold jackets, there is a large heat transfer and cooling area.

The cover----- According to user requirements and process conditions, the cover can be designed as a flat cover or an arch cover; it can be designed as an overall opening, or it can be designed with a several-piece opening; it can be opened manually or pneumatically; various pipe openings are opened on the cover as needed.

| Model | Total Volume | Working Volume | Overall dimension(mm) | Weight(kg) | ||||

| M3 | ft3 | M3 | ft3 | Long | Width | High | ||

| TOPH2042-1/4 | 0.008 | 0.28 | 0.0056 | 0.196 | 700 | 232 | 500 | 70 |

| TOPH2042-5 | 0.2 | 7.1 | 0.14 | 5 | 1700 | 1000 | 1030 | 450 |

| TOPH2042-10 | 0.37 | 13.1 | 0.26 | 9.2 | 2200 | 1020 | 1000 | 600 |

| TOPH2042-36 | 1.15 | 40.6 | 0.8 | 28 | 3010 | 1810 | 1200 | 1800 |

| TOPH2042-100 | 3.1 | 109.5 | 2.2 | 77 | 4210 | 2300 | 2184 | 4000 |

| TOPH2042-120 | 3.7 | 130.7 | 2.6 | 92 | 4275 | 2380 | 2210 | 4262 |

| TOPH2042-155 | 4.7 | 166 | 3.3 | 116 | 4350 | 2650 | 2240 | 5700 |

| TOPH2042-180 | 5.5 | 194.2 | 3.9 | 136 | 4900 | 2870 | 2280 | 7600 |

| TOPH2042-215 | 6.6 | 233.1 | 4.6 | 163 | 5300 | 3100 | 2300 | 8900 |

| TOPH2042-385 | 12 | 423.7 | 8.4 | 297 | 5900 | 4000 | 3200 | 17000 |

| TOPH2042-515 | 16 | 565 | 11.2 | 396 | 6452 | 4000 | 3200 | 20000 |

| TOPH2042-600 | 18 | 635.6 | 12.6 | 445 | 6452 | 4000 | 3530 | 22000 |

English

English