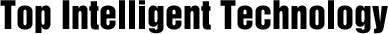

TOPH61 Series ZJH Homogenizer

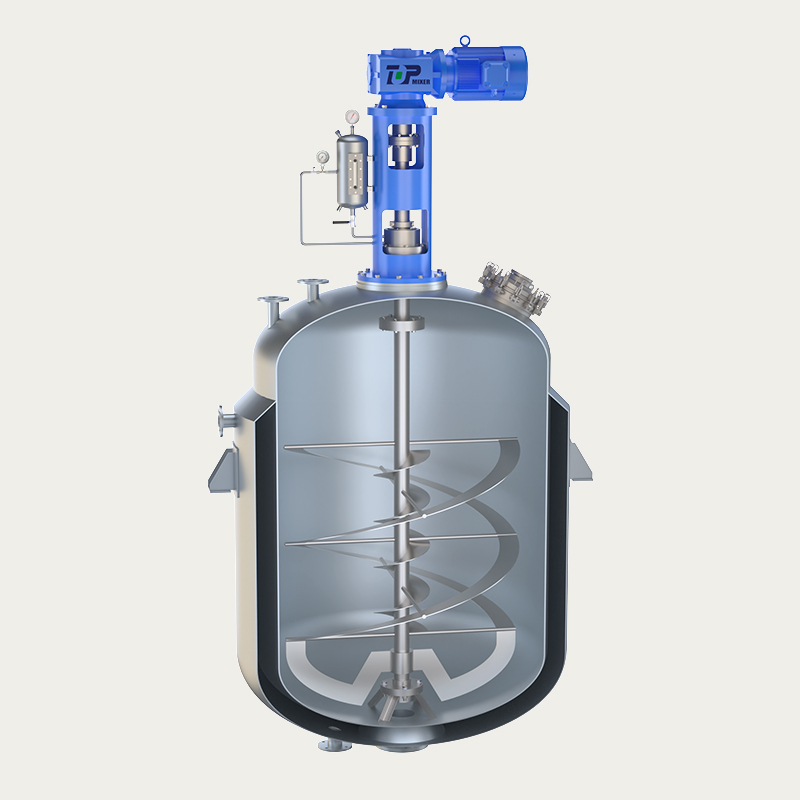

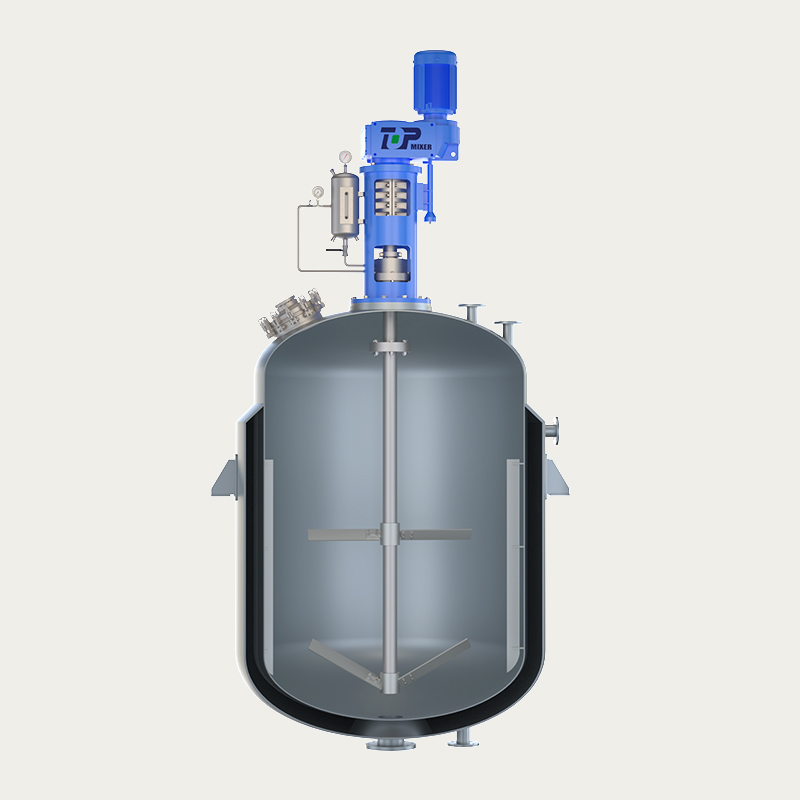

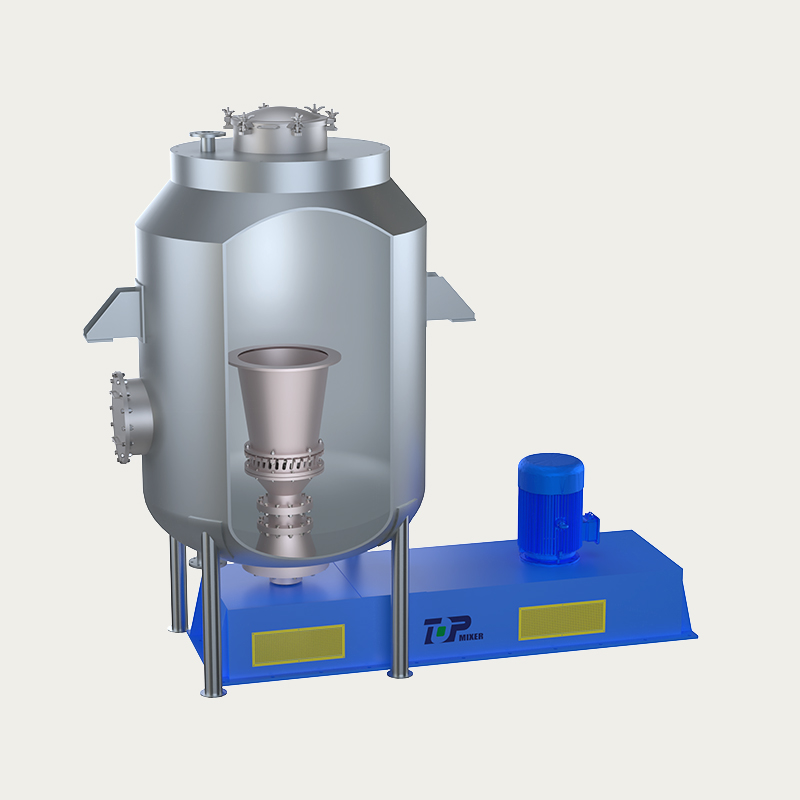

ZJH homogenous mixer is a patented product developed by our company in combination with advanced foreign technologies and is complementary to the RHⅡ homogenous mixer. Suitable for the production of high-viscosity materials such as foundation, cream, and toothpaste. Its biggest feature is that the internal and external circulation homogenizer can enable the material to work in the internal and external circulation homogenization state so that the material can achieve a good emulsification effect.

This homogenous mixer is professionally designed according to the paste-making process of cosmetics and ointments. This unit consists of a pretreatment pot, vacuum emulsification mixing pot, vacuum pump, hydraulic system, material pouring system, electrical control system, working platform, and other parts. This unit is simple to operate, has stable performance, good homogeneous performance, high production efficiency, convenient cleaning, reasonable structure, small footprint, and high automation.

Features

● The stirring adopts frequency conversion speed to adjust the stirring line speed at will within 0~150m/min to meet different process requirements.

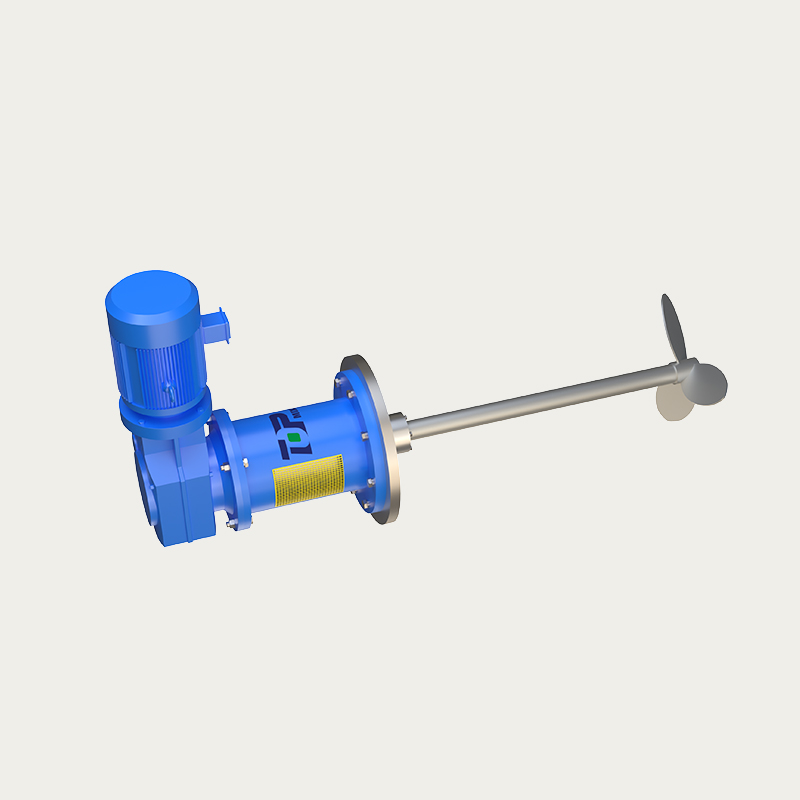

● Advanced homogenizer adopts the latest technology of our company, with unique structure and excellent efficiency.

● All contact materials are made of imported stainless steel material, and the inner surface of the container is polished 300EMSH (sanitary grade), which meets sanitary requirements.

● Vacuum suction, vacuum defoaming, the entire process is completed in a vacuum state, without bacterial infection, and prolongs the product shelf life.

● The shape is beautiful and elegant, and the appearance adopts special polishing technology, and the luster is like a mirror.

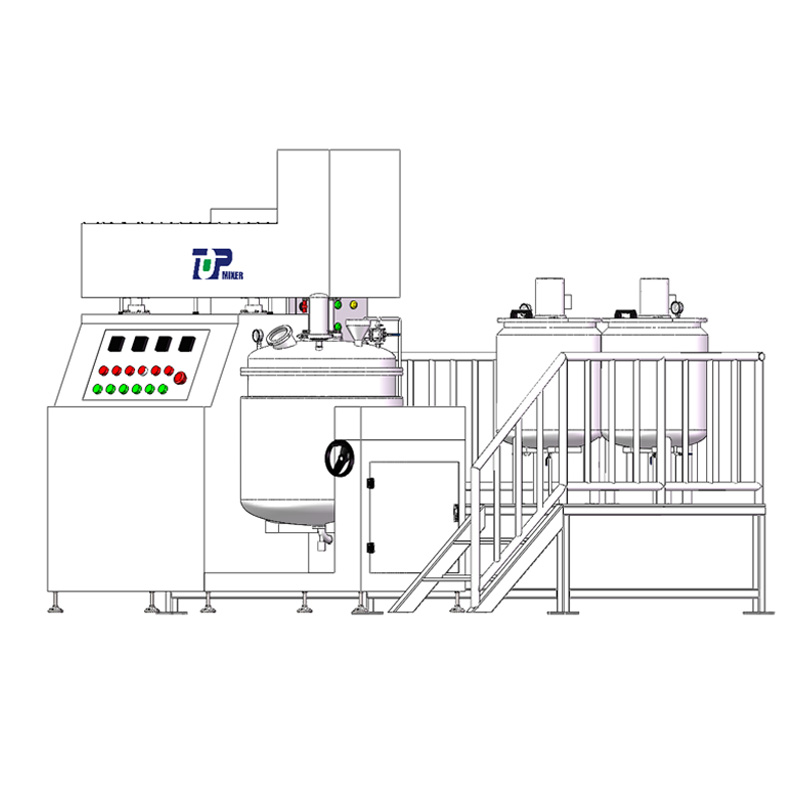

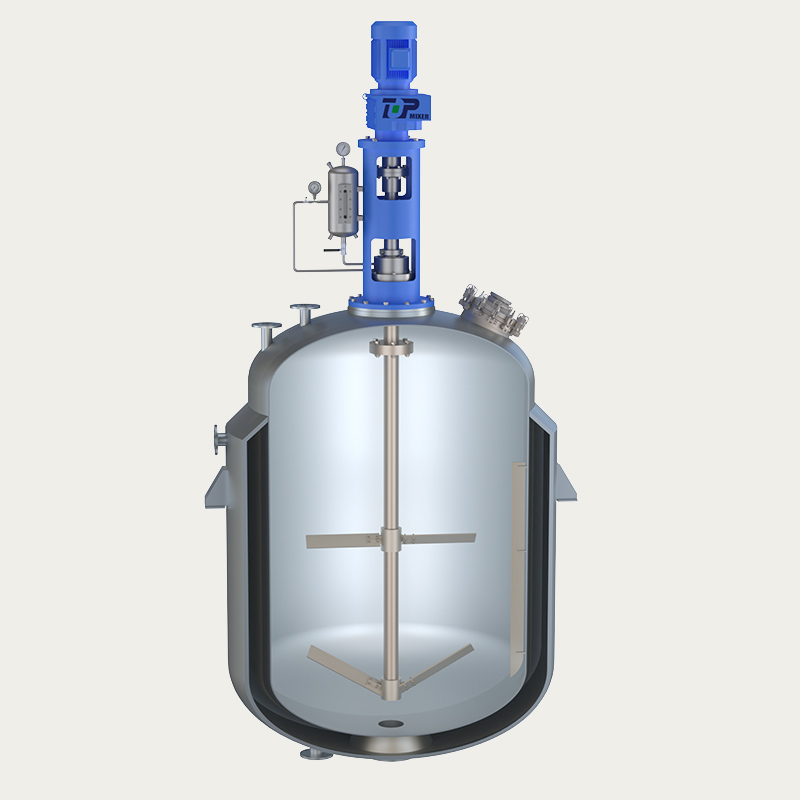

How it works

The emulsifier consists of an emulsifier pot, a water phase pot, an oil phase pot, a vacuum device, a temperature control system, an electrical control system, etc. The oil-soluble and water-soluble raw materials are melted or dissolved in the oil-phase pot and the water-phase pot, respectively. The temperature is generally maintained at around 80°C. The oil-phase and water-phase raw materials heated with water vapor are added to the emulsification pot through a filter for homogenous stirring, emulsification, and vacuum degassing. Then, cold water is applied to the jacket, and after cooling to a certain temperature, add flavor, continue to cool to the required temperature, and stop stirring, and the material can be discharged after the normal pressure is restored.

Things to note

● The homogenous cutting head must not be operated in an empty pot due to its extremely high speed, so as not to affect the sealing degree after local heating.

● The ground wire is reliably grounded to ensure safety in electricity use.

● The shaft end of the homogenizer is turned right. Each time the motor is connected or re-activated for a long time, you should activate and try turning. After confirming that it is correct, you should officially let the homogenizer run.

● Before each stirring starts, jog it to check whether there are any abnormalities in the stirring wall, and if there are any, they should be eliminated immediately.

● Before vacuum work, be sure to check whether the pot is flat with the pot cover, whether the pot mouth, material mouth cover, etc. are tightly covered, and whether the seal is reliable.

● Before the vacuum pump is turned off, the ball valve in front of the vacuum pump should be closed.

● The vacuum pump can be started and operated under the sealing condition of the homogenized pot. If there is a special need, open the atmospheric start pump and run for more than 3 minutes.

● The equipment must be powered off before any maintenance or cleaning is performed.

● Never put your hands into the kettle during the operation of the equipment to prevent accidents.

● If there is any abnormal response during operation, stop running immediately and wait until the cause is found.

Application

● Food ● Pharmaceuticals ● Cosmetics

| Model | Product volume (L) | Stir motor | Homogenous motor | Container size (mm) | Extreme vacuum (Pas) | Hydraulic power (kW) | Weight (kg) | ||||

| Maintenance pot | Water phase pot | Oil phase pot | Power (kW) | Speed (rpm) | Power (kW) | Speed (rpm) | |||||

| TOPH2061-10 | 10 | 8 | 5 | 0.25 | 0~63 | 0.55 | 0~3000 | ∅200×250 | -0.09 | 0.55 | 550 |

| TOPH2061-20 | 20 | 16 | 10 | 0.37 | 0~63 | 1.5 | 0~3000 | ∅300×300 | -0.09 | 0.55 | 750 |

| TOPH2061-50 | 50 | 40 | 25 | 0.75 | 0~63 | 2.2 | 0~3000 | ∅400×400 | -0.09 | 0.75 | 1100 |

| TOPH2061-100 | 100 | 80 | 50 | 1.5 | 0~63 | 4 | 0~3000 | ∅500×550 | -0.09 | 0.75 | 1500 |

| TOPH2061-200 | 200 | 160 | 100 | 2.2 | 0~63 | 5.5 | 0~3000 | ∅600×700 | -0.09 | 0.75 | 1500 |

| TOPH2061-500 | 500 | 400 | 250 | 4 | 0~63 | 7.5 | 0~3000 | ∅800×1000 | -0.09 | 1.1 | 2200 |

| TOPH2061-1000 | 1000 | 800 | 500 | 5.5 | 0~63 | 11 | 0~3000 | ∅1100×1200 | -0.09 | 1.1 | 2500 |

English

English