Introduction to High Temperature Stirring System

High-temperature mixing systems are devices used to mix materials in high-temperature environments, and are widely used in industries such as chemical, pharmaceutical, metallurgical, glass, and food processing. Our company provides design and manufacturing services for mixing processes above 400°C, requiring reliable mechanical seal technology to handle process temperatures from 500°C to 750°C.

High-temperature mixing systems are devices used to mix materials in high-temperature environments, and are widely used in industries such as chemical, pharmaceutical, metallurgical, glass, and food processing. Our company provides design and manufacturing services for mixing processes above 400°C, requiring reliable mechanical seal technology to handle process temperatures from 500°C to 750°C.

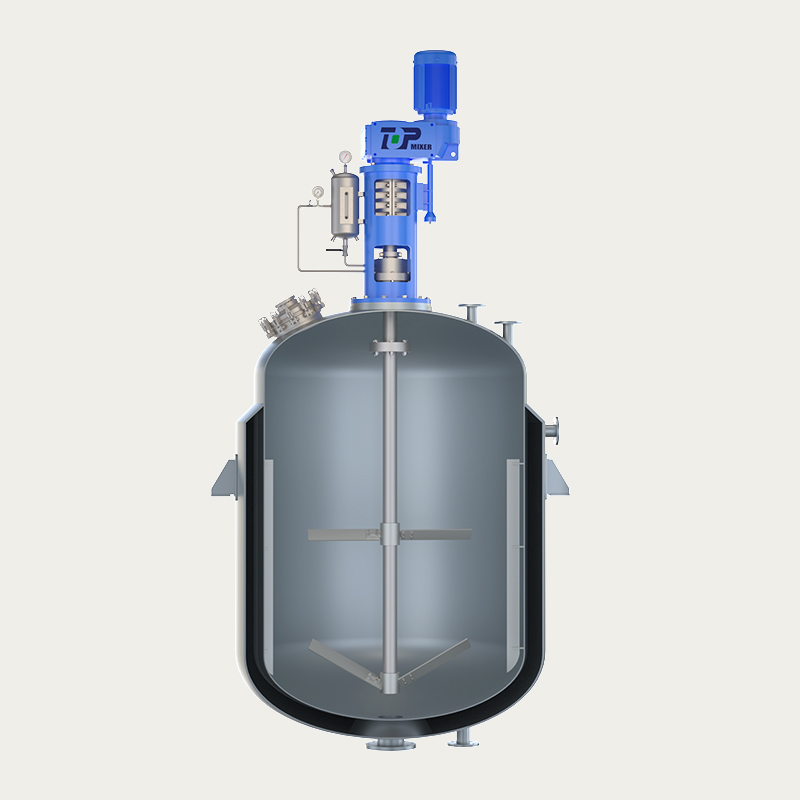

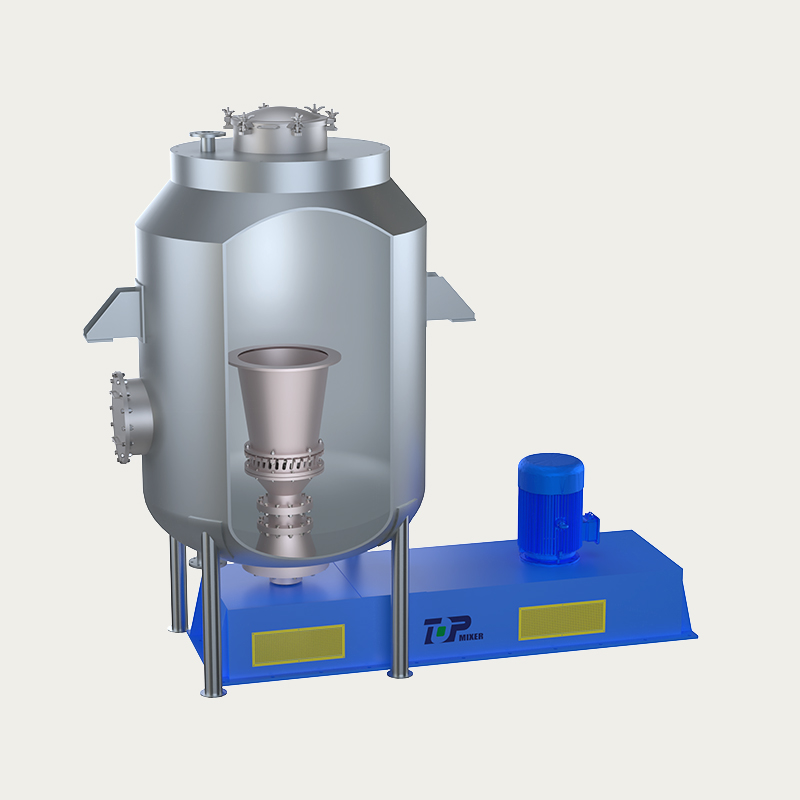

1. Composition and Structure

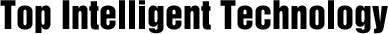

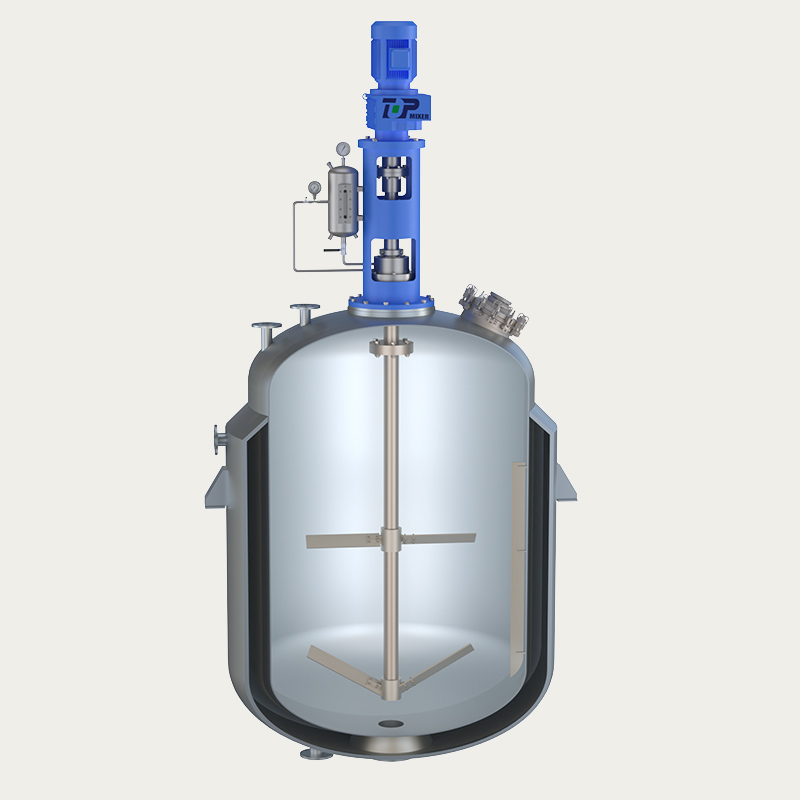

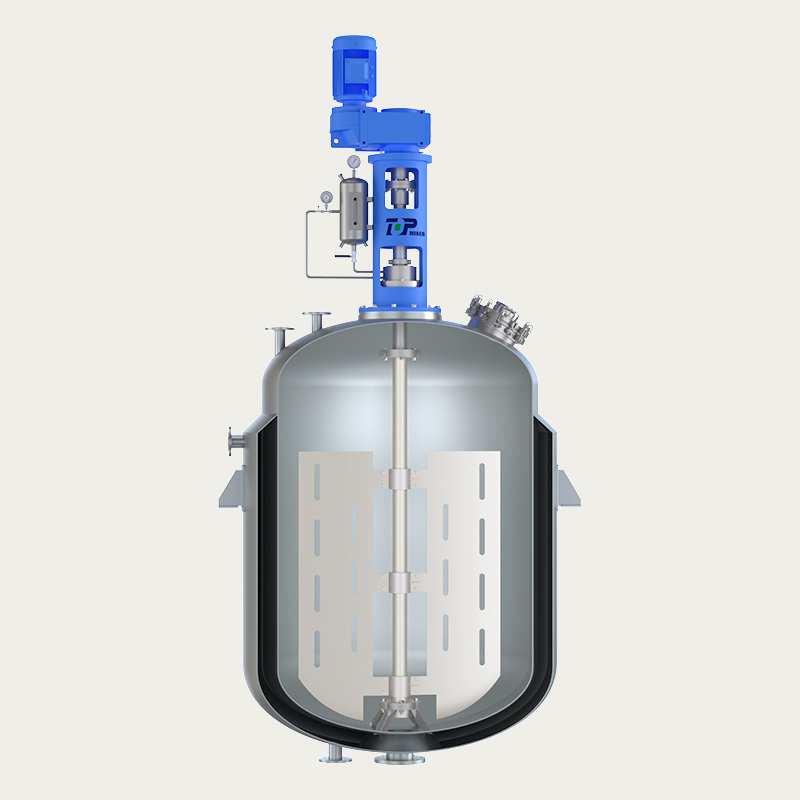

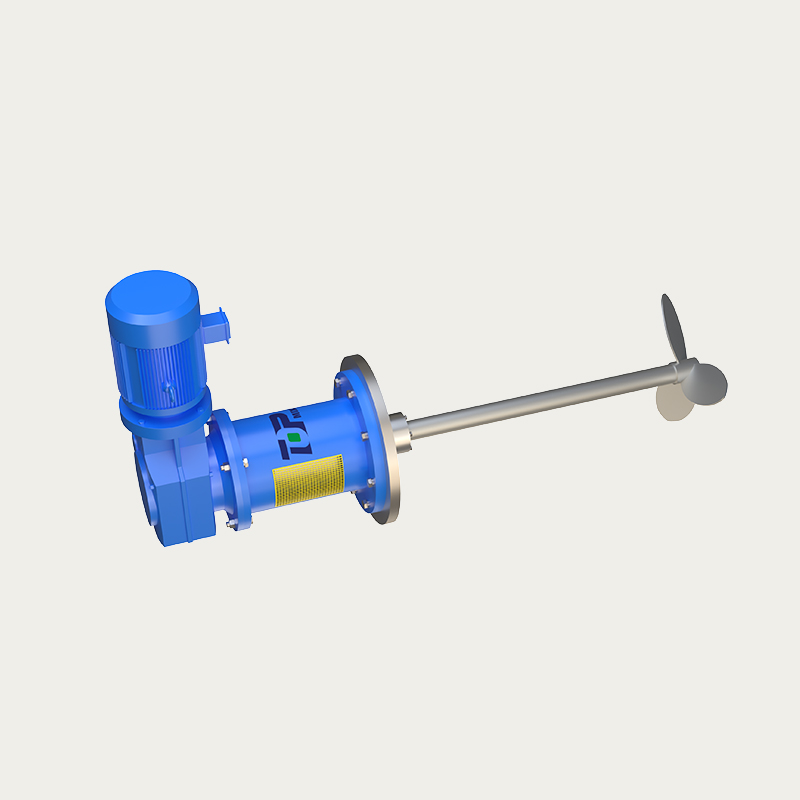

Agitation device: This includes components such as agitator, agitator shaft, and drive motor. The shape and size of the agitator are designed according to the properties of the material and agitation requirements, such as turbine type, spiral type, and paddle type.

Heating system: Used to provide a high-temperature environment, common heating methods include electric heating, steam heating, and oil bath heating. The heating system requires precise temperature control to meet process requirements.

Sealing systems: These prevent the leakage of high-temperature materials. Common sealing methods include mechanical seals and magnetic seals. Mechanical seals are suitable for high-temperature and high-pressure environments, while magnetic seals transmit power through a magnetic field to prevent leakage.

Control system: Includes temperature controller, speed controller, motor driver, etc., used to achieve precise control of stirring speed and temperature. Modern high-temperature stirring systems are usually equipped with PLC or touch screen operating interface to achieve automated control.

Auxiliary systems include cooling systems and nitrogen protection systems. Cooling systems reduce the temperature of the stirring shaft and motor to prevent overheating damage; nitrogen protection systems prevent material oxidation or combustion.

2. Technical Features

High temperature resistance: The system materials must have good high temperature resistance, such as using high temperature resistant alloys, ceramics and other materials, to ensure stable operation in high temperature environments.

Sealing performance: Advanced sealing technologies, such as liquid lubricated mechanical seals and magnetic coupling seals, are used to prevent leakage of high-temperature materials and ensure operational safety.

Precise control: The PID control algorithm enables precise control of temperature and stirring speed, ensuring uniform mixing of materials and stable reaction conditions.

Energy efficient: Optimize heating and cooling systems to reduce energy loss and improve energy utilization efficiency.

Safe and reliable: Equipped with multiple safety protection devices, such as overheat protection, overload protection, and leakage alarm, to ensure safe operation of the equipment.

3. Application Scenarios

Chemical industry: Used in high-temperature polymerization reactions, esterification reactions, etc., to ensure that reactants are fully mixed and improve reaction efficiency.

In the pharmaceutical industry, during processes such as high-temperature sterilization and drug synthesis, it is essential to ensure uniform mixing of materials to avoid localized overheating or incomplete reactions.

In the metallurgical industry, such as high-temperature smelting and metal extraction, stirring promotes the separation of metal and slag, thereby increasing the metal recovery rate.

In the glass industry, stirring helps to remove air bubbles from the glass during the glass melting process, making the glass melt more uniform and improving product quality.

Food processing: such as high-temperature sterilization of sauces and chocolate refining, to ensure that food maintains its quality and taste during high-temperature processing.

4. Strengths and Challenges

Advantages:

Improve material mixing efficiency and ensure uniformity in reaction or processing.

Precise control of temperature and stirring speed meets different process requirements.

An efficient sealing and cooling system ensures safe operation of the equipment.

challenge:

High-temperature environments require materials with high durability and stability, which increases equipment costs.

The reliability of the sealing system is crucial, as leaks can lead to safety incidents.

The design and maintenance of high-temperature stirring systems require professional technical support.

English

English