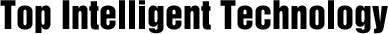

TOPH52 Series SH Three-Shaft Double-Column Mixer

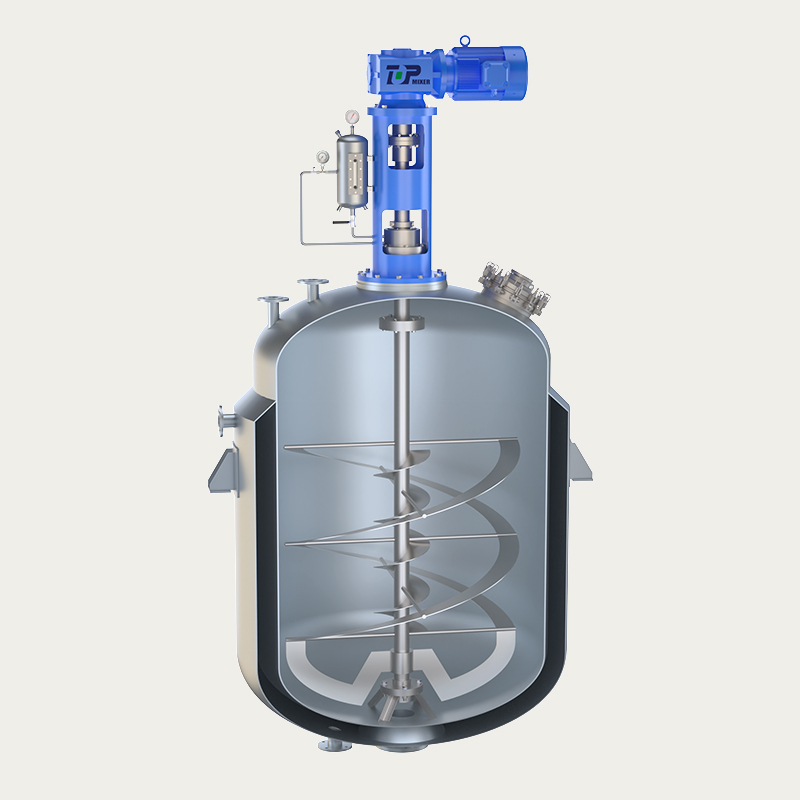

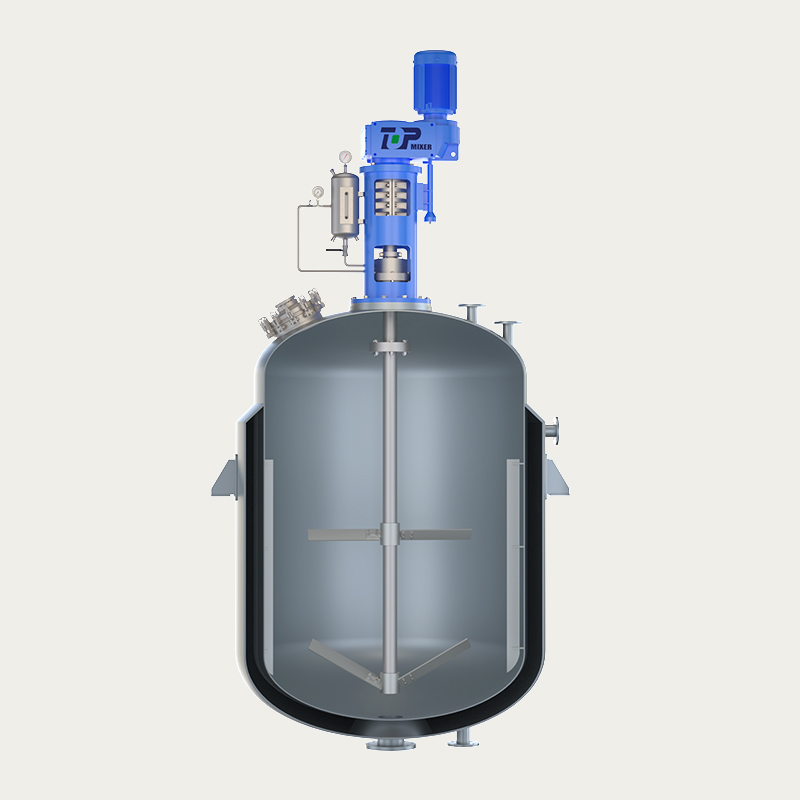

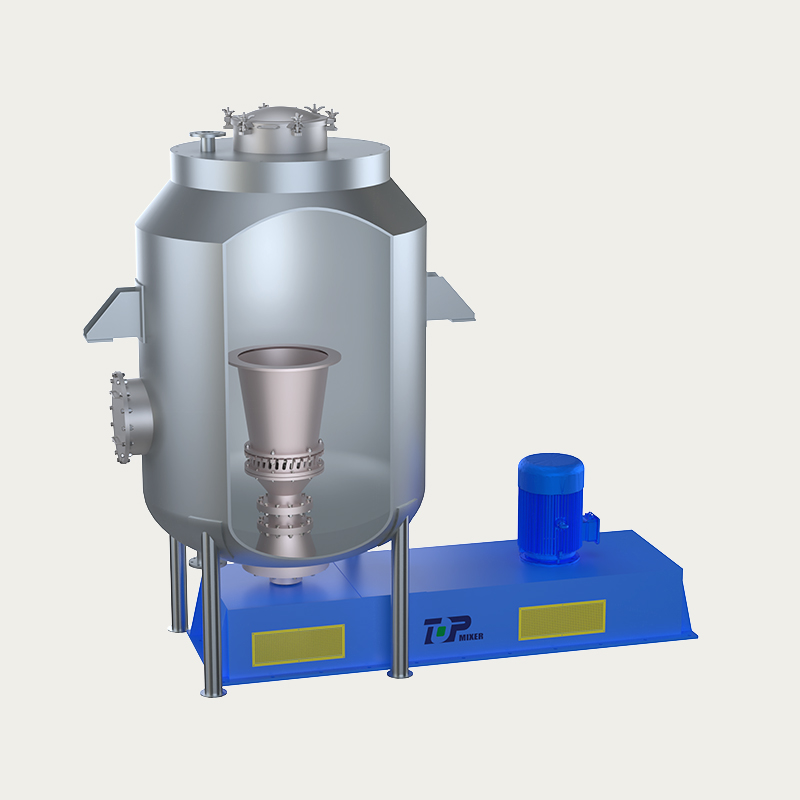

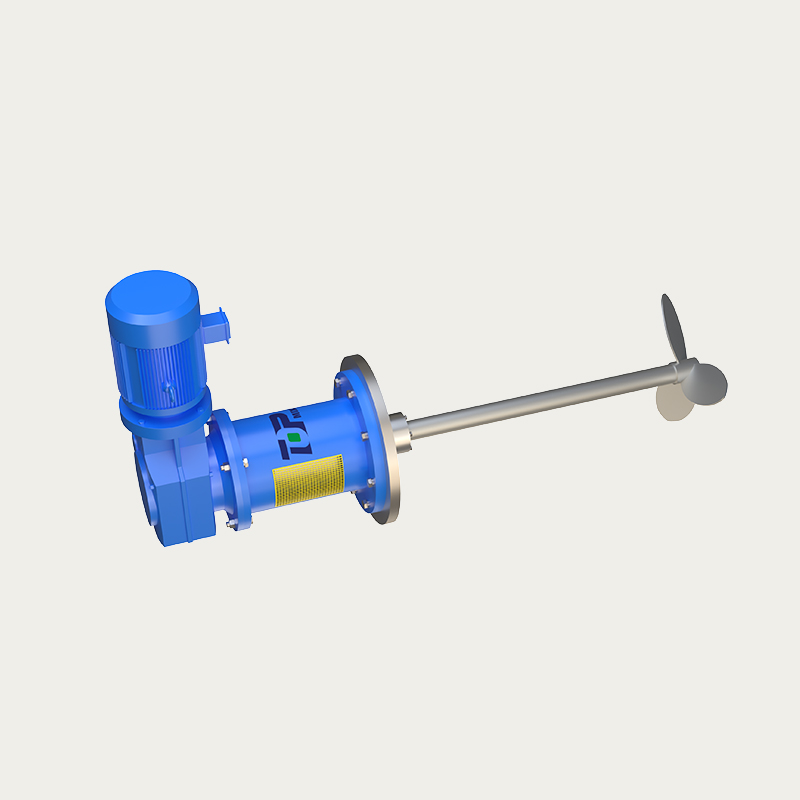

The three-axle multi-function dual-column strong dispersion and mixing mixer is a product with strong dispersion and mixing functions developed on the basis of a hydraulic lifting single-axle mixer. The conventional form is a high-speed dispersion mixer combined with anchor-type wall scraping stirring, which has an extremely strong shearing effect and extremely high mixing efficiency. The product is very adaptable to medium-high viscosity and thixotropic materials; one of the sets of high-speed dispersers can replace medium-speed mixers, and the mixing methods are optional, such as screws, blades, frames, etc., and the good mixing form can be designed according to the characteristics of the material and production process.

Material Viscosity: ≤1500000cps

Production Capacity: 50-2000L

Application Field: Suitable for dispersing and mixing materials in coatings, putty, inks, adhesives, energy, electronics and electrical appliances, pharmaceuticals, cosmetics, food, and other industries.

Applicable materials: Various slurries with a material viscosity below 100000 cps and a solid content below 90%; such as battery slurry, solder paste, ceramic slurry, silicone ink, sealant, structural glue, soft ointment, jam, etc., more than a thousand kinds of materials.

How it works

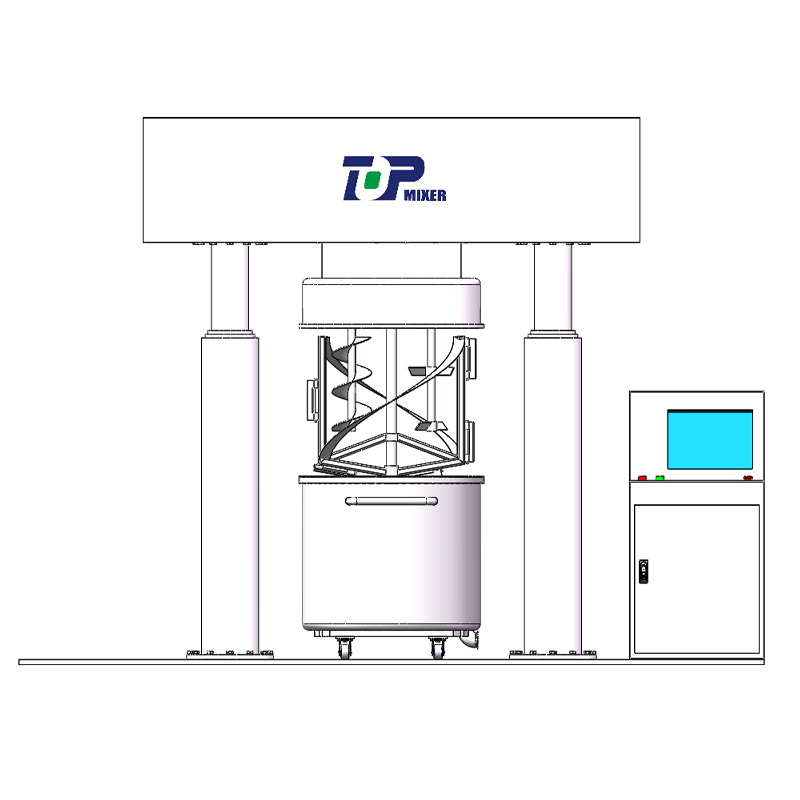

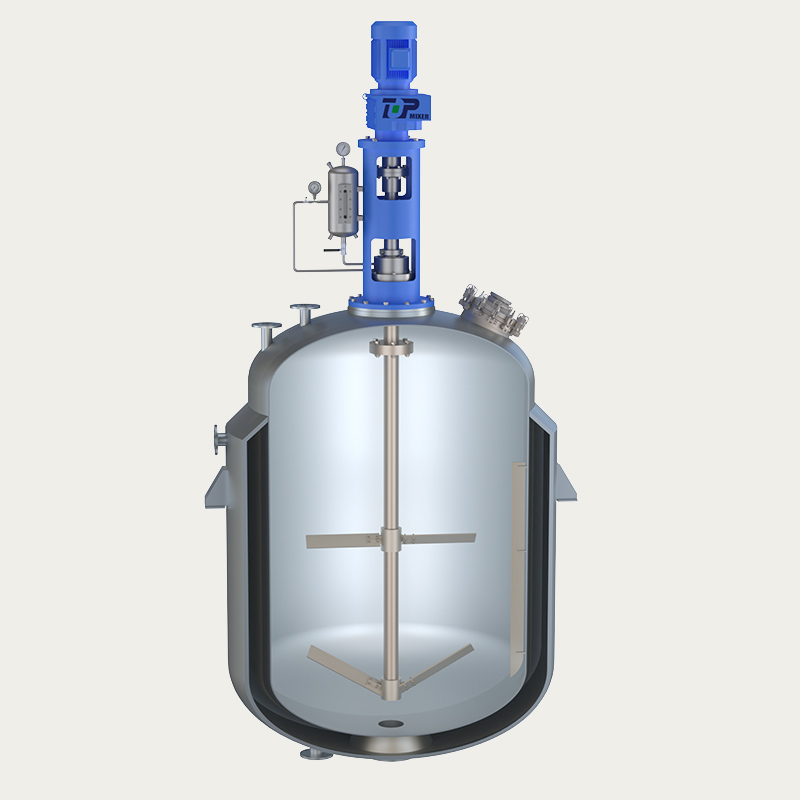

The stirring paddle rotates in a fixed direction under the drive of the power unit; during the rotation process, the material is driven to rotate in axial and radial directions. The materials in the mixer have both axial and circular motions, so there are several stirring forms such as shear stirring and diffusion stirring. It can effectively stir and mix the materials quickly. The dispersion disk runs at high speed, causing the material to flow in an annular shape, creating a strong vortex, which descends to the bottom of the vortex in a spiral shape. A strong shear impact and friction occur between the particles, achieving rapid wastewater and dissolution functions. The stirring plate is moved through circular motion, which produces a better radial effect, accelerates material circulation, and improves dispersion efficiency. The hydraulic lifting mixer drives the hydraulic plunger to lift and lower through the hydraulic pump, driving the entire transmission mechanism and working group to lift and lower.

| Model | Stirring power (kW) | Effective volume (L) | Container size (mm) | Extreme vacuum (Pas) | Electro-hydraulic power (kW) | Equipment weight (kg) |

| TOPH2052-100 | 4 | 100L | ∅500*600 | -0.09 | 0.55 | 550 |

| TOPH2052-200 | 5.5 | 200L | ∅600*800 | -0.09 | 0.55 | 750 |

| TOPH2052-300 | 7.5 | 300L | ∅700*800 | -0.09 | 0.75 | 1100 |

| TOPH2052-500 | 11 | 500L | ∅800*1000 | -0.09 | 0.75 | 1500 |

| TOPH2052-800 | 15 | 800L | ∅1000*1000 | -0.09 | 0.75 | 1500 |

| TOPH2052-1000 | 18.5 | 1000L | ∅1100*1100 | -0.09 | 1.1 | 2200 |

| TOPH2052-1500 | 22 | 1500L | ∅1200*1400 | -0.09 | 1.1 | 2500 |

English

English