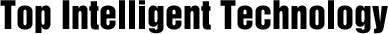

TOPH41 Series U-Shaped Ribbon Mixer

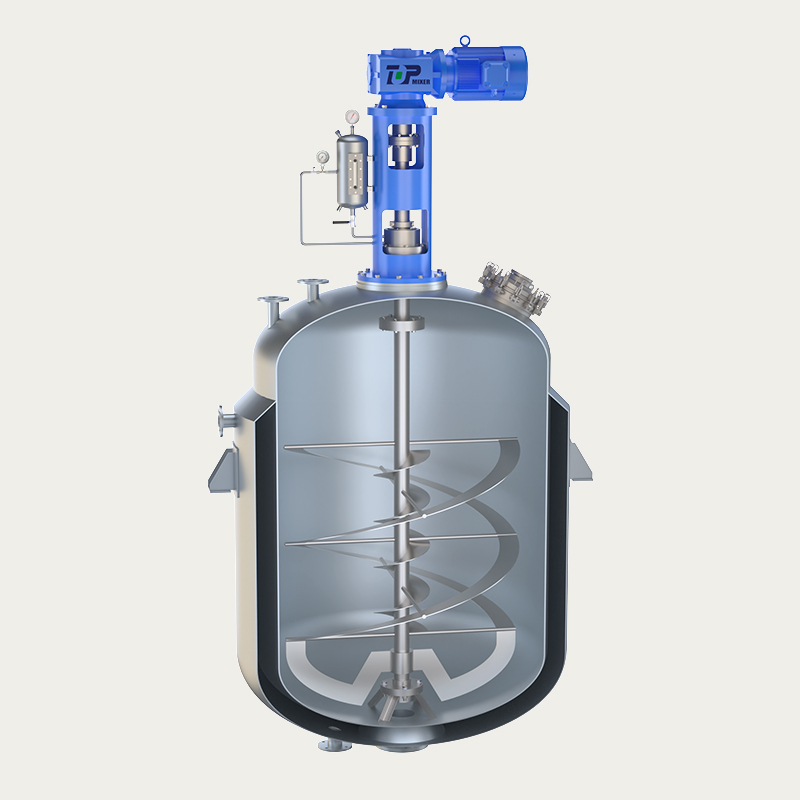

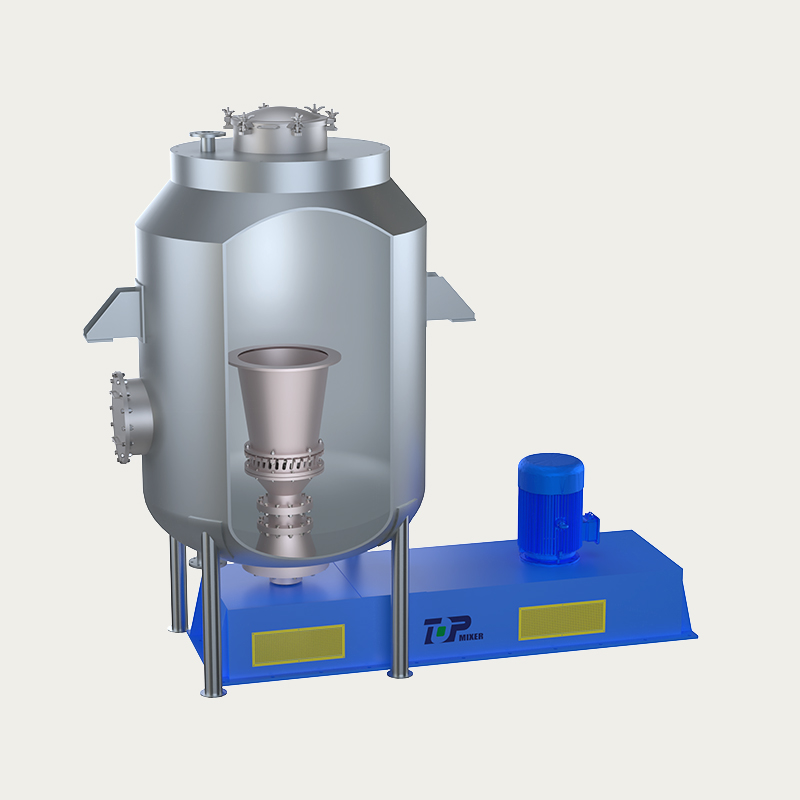

The working volume of the screw mixer is from 0.014m3-14.5m3. The different power and speeds meet more requirements. Its characteristic is that the equipment can be coordinated well with your machine. It has a vacuum and hot and cold jackets. The materials can be selected at any time. The intermediate or bottom discharge design is available. The cutter and a variety of filler boxes are available. Plus its unique four optional screw arrangement forms make the materials evenly mixed.

Features

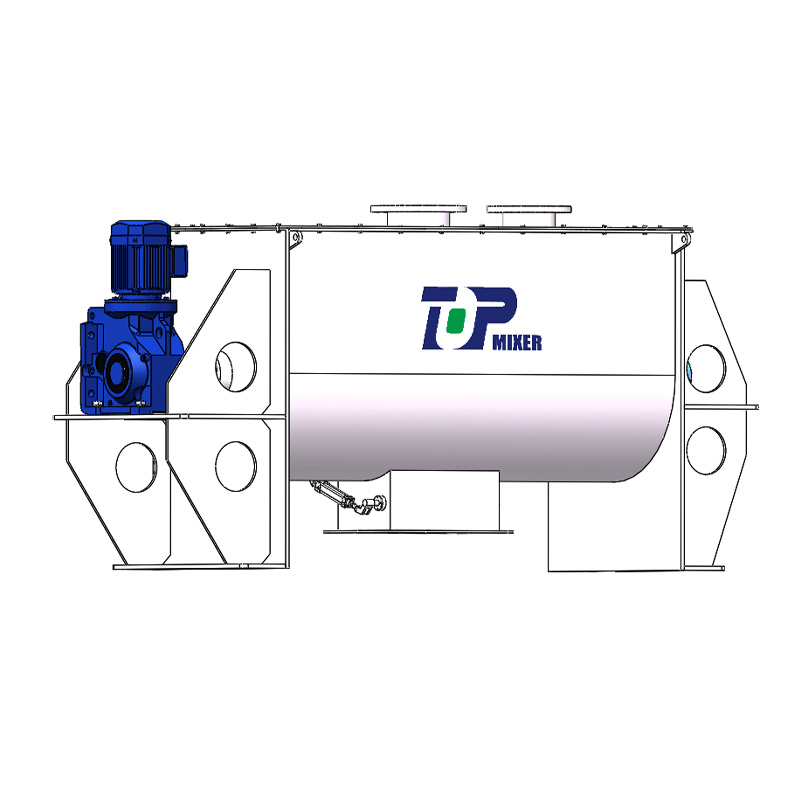

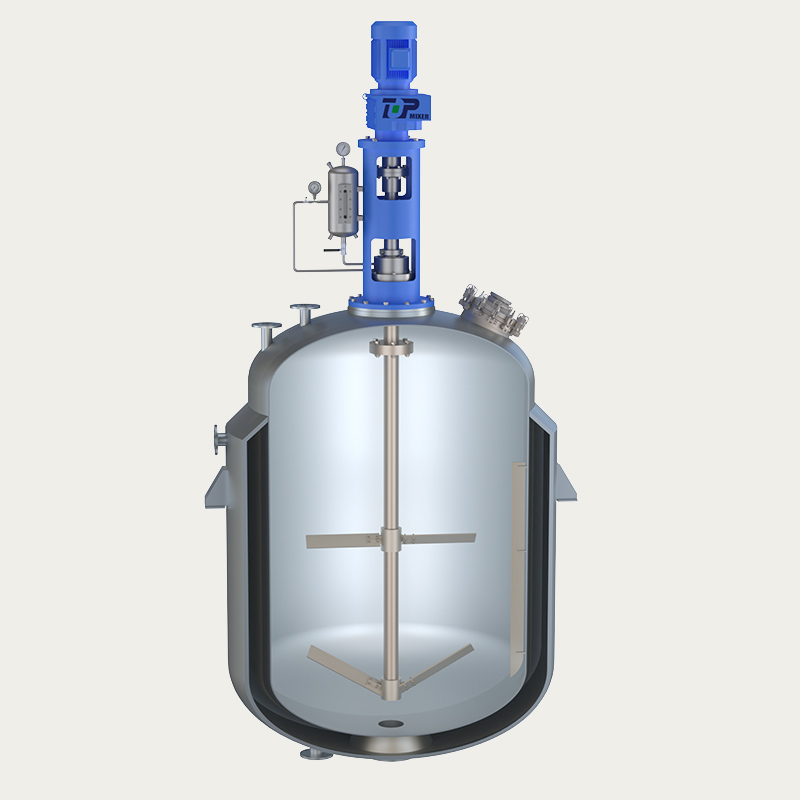

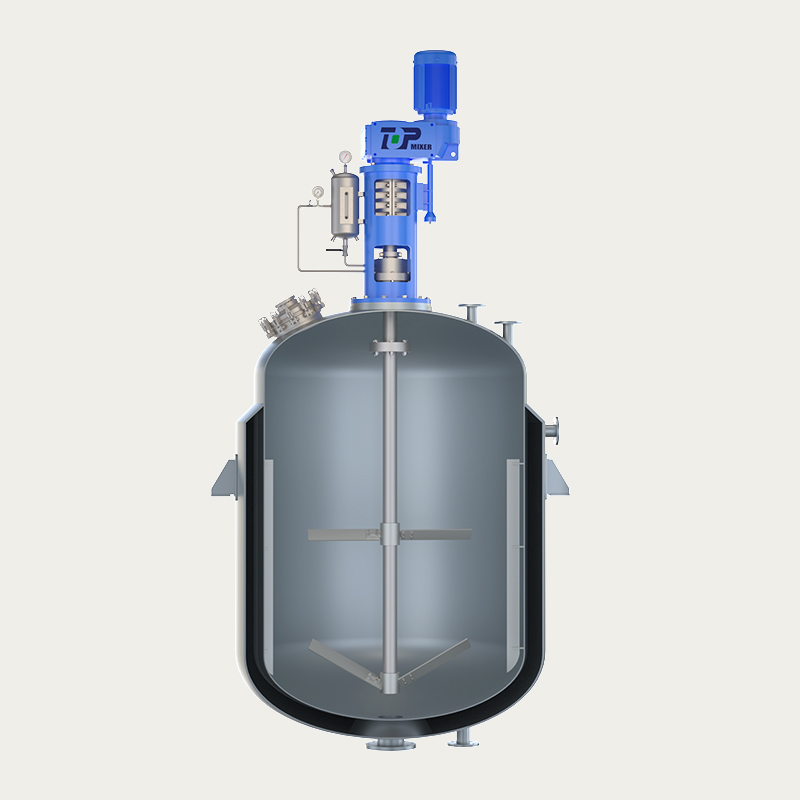

It consists of a U-shaped container, screw stirring blade, and transmission component: a U-shaped long cylinder structure ensures the small resistance movement of the mixed material (powder, semi-fluid) in the cylinder. The forward and reverse rotating screws are installed on the same horizontal axis to form a low-power and efficient mixing environment. The screw ribbon-shaped blades are generally made into double or triple layers. The outer spiral collects the material from both sides to the center, and the inner spiral transports the material from the center to both sides, which can make the material form more vortex during flow. Speed up the mixing speed and improve mixing uniformity. It is generally used for mixing viscous or cohesive powder particles and mixing liquid and paste materials to the powder particles. Due to the difficulty in cleaning viscous materials, it is suitable for long-term mixing of large yields and infrequently changed varieties.

Material delivery method

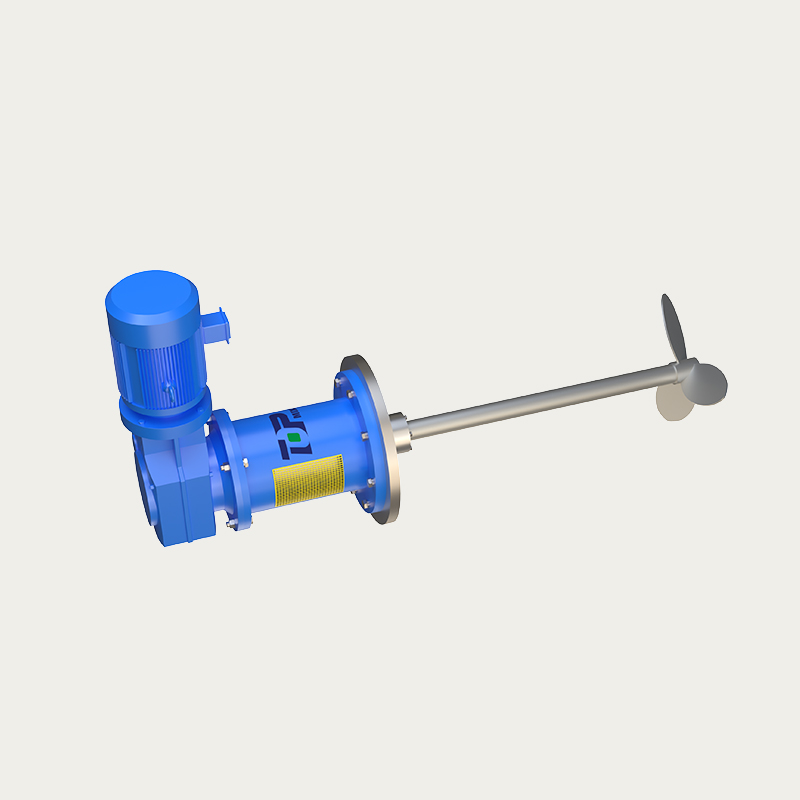

The powder material adopts a pneumatic large door open structure, which has the advantages of fast unloading and no residues; high-fine materials or semi-fluid materials use manual butterfly valves or pneumatic butterfly valves. A heating or cooling jacket can be configured. There are two ways to heat electric heating and thermal oil heating. The cooling process can directly inject cooling water into the jacket, with a large heat exchange area and a fast cooling speed. The small mixer adopts the direct connection method of reducer, which has a simple structure, high reliability in operation,n and convenient maintenance. Large-sized mixers use pulleys to drive cycloid reducer to drive, and the elastic connection of belt transmission has the advantage of protecting transmission components when overloaded.

Discharge control

Manual self-locking mechanism, pneumatic drive device.

Application areas

The screw mixer is mainly used in industrial industries such as pharmaceuticals, food, chemicals, pesticides, plastics, pigments and cosmetics.

| Model(L) | Production capacity (kg/time) | Mixing time (min) | Power (kW) | Spindle speed (r/min) | Weight of the whole machine (kg) | Size (m) |

| TOPH2041-200 | 80-120 | 45889 | 3-5.5 | 65 | 450 | 1.6*0.7*1.1 |

| TOPH2041-500 | 200-300 | 45889 | 45758 | 60 | 900 | 2.32*0.73*1.13 |

| TOPH2041-1000 | 400-600 | 45889 | 7.5-15 | 42 | 1400 | 2.8*0.92*1.32 |

| TOPH2041-2000 | 800-1200 | 45889 | 15-22 | 32 | 2500 | 3.31*1.12*1.64 |

| TOPH2041-3000 | 1200-1800 | 45889 | 18.5-30 | 32 | 3100 | 3.75*1.29*1.82 |

English

English