Introduction to High-Shear Emulsifiers

A high-shear emulsifier is an industrial device that uses high shear force generated by mechanical action to mix, emulsify, disperse, and homogenize immiscible liquid, solid, and gaseous materials. It is widely used in the food, chemical, pharmaceutical, and cosmetic industries, efficiently refining and uniformly distributing materials to form stable emulsions or suspensions.

A high-shear emulsifier is an industrial device that uses high shear force generated by mechanical action to mix, emulsify, disperse, and homogenize immiscible liquid, solid, and gaseous materials. It is widely used in the food, chemical, pharmaceutical, and cosmetic industries, efficiently refining and uniformly distributing materials to form stable emulsions or suspensions.

1. Working principle

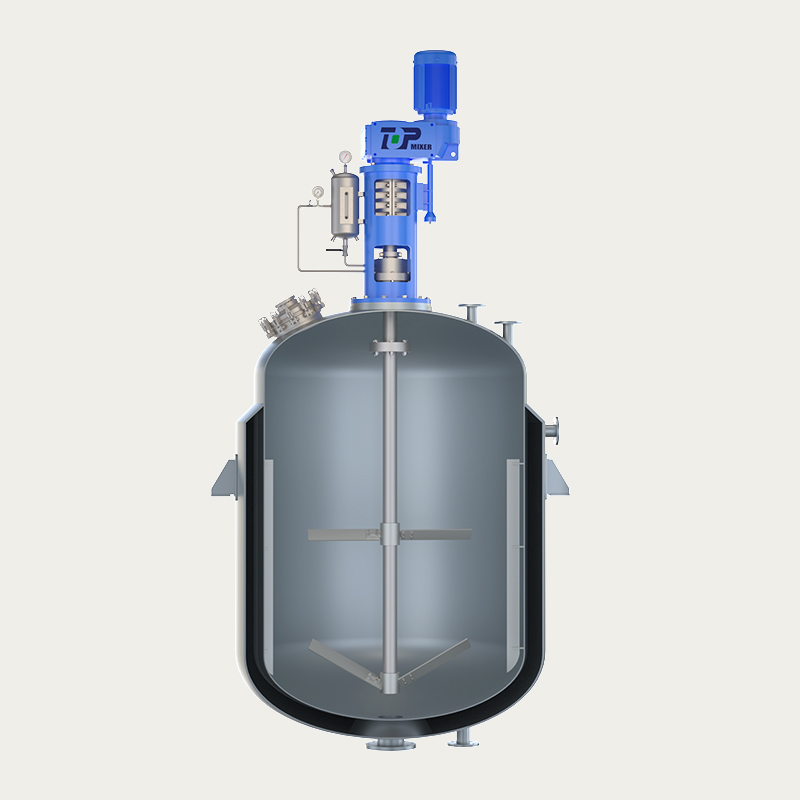

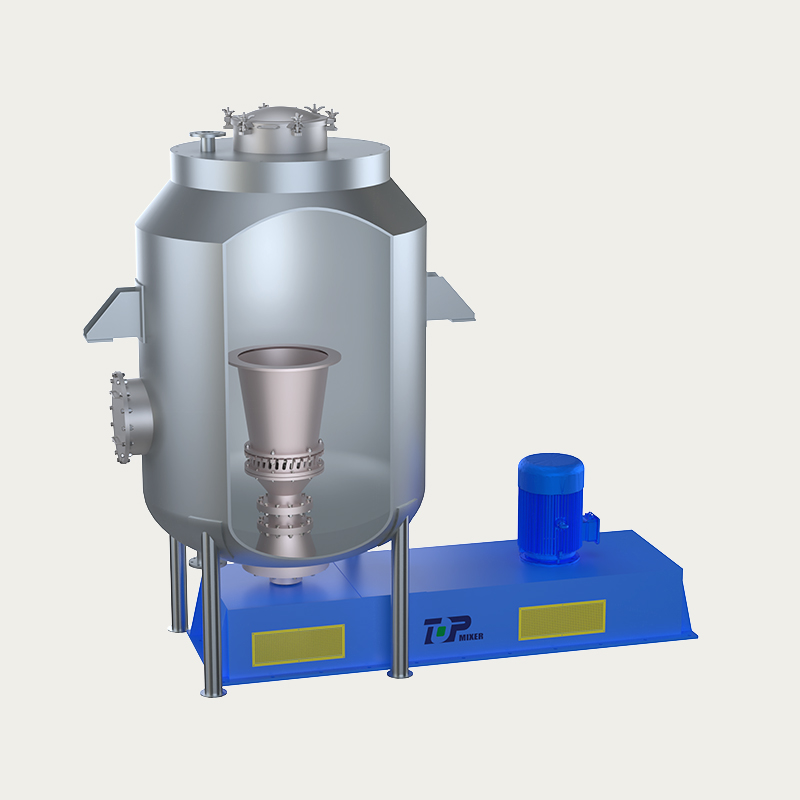

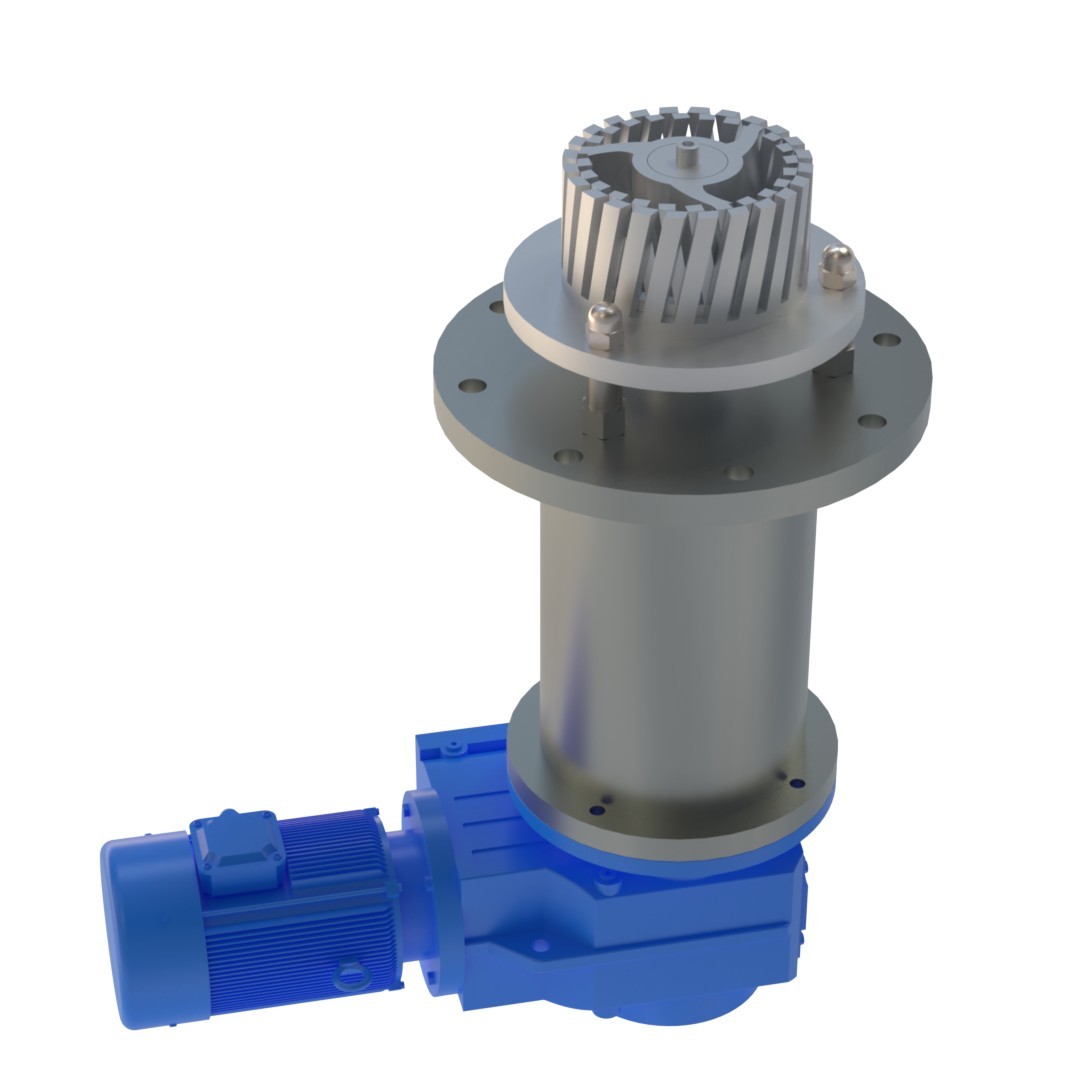

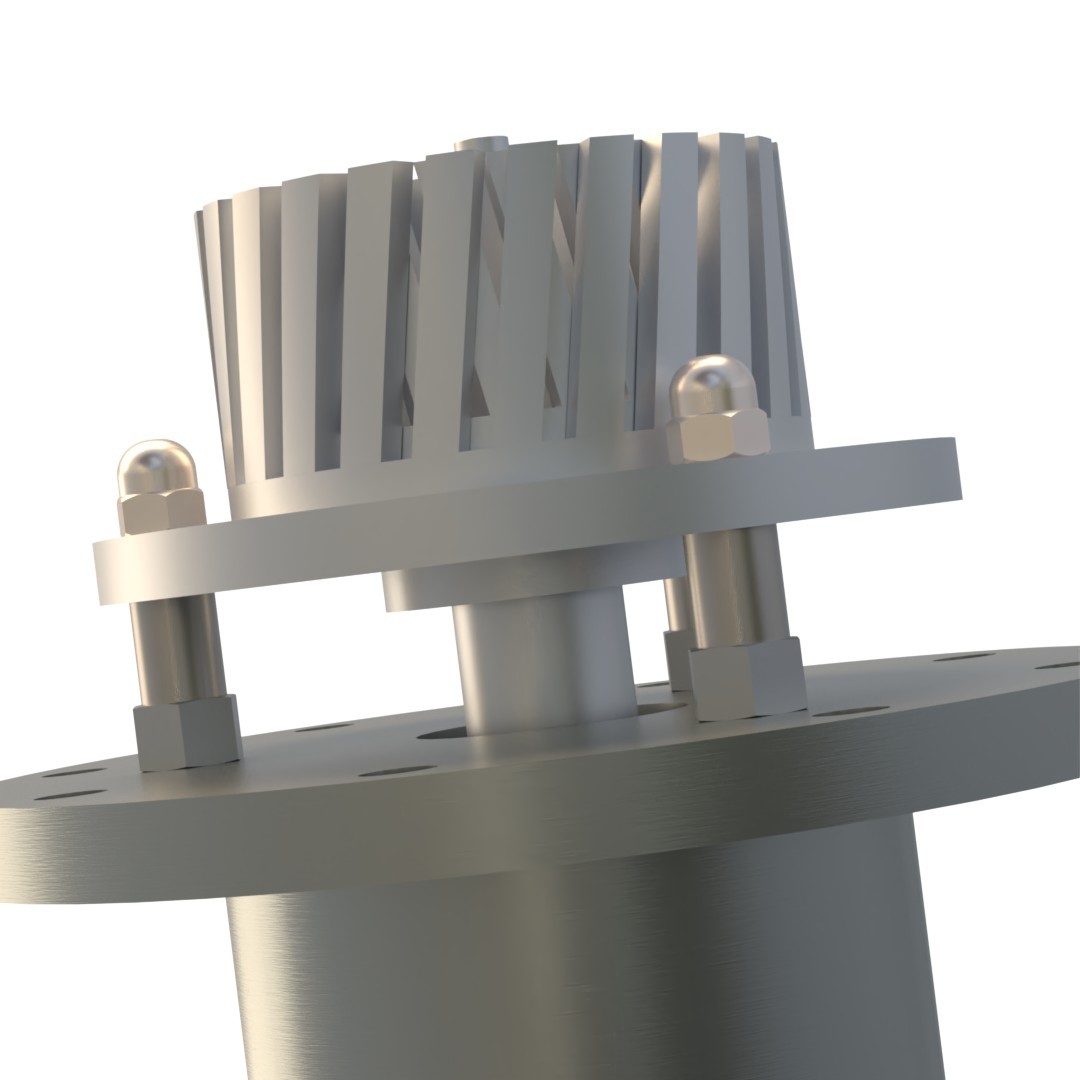

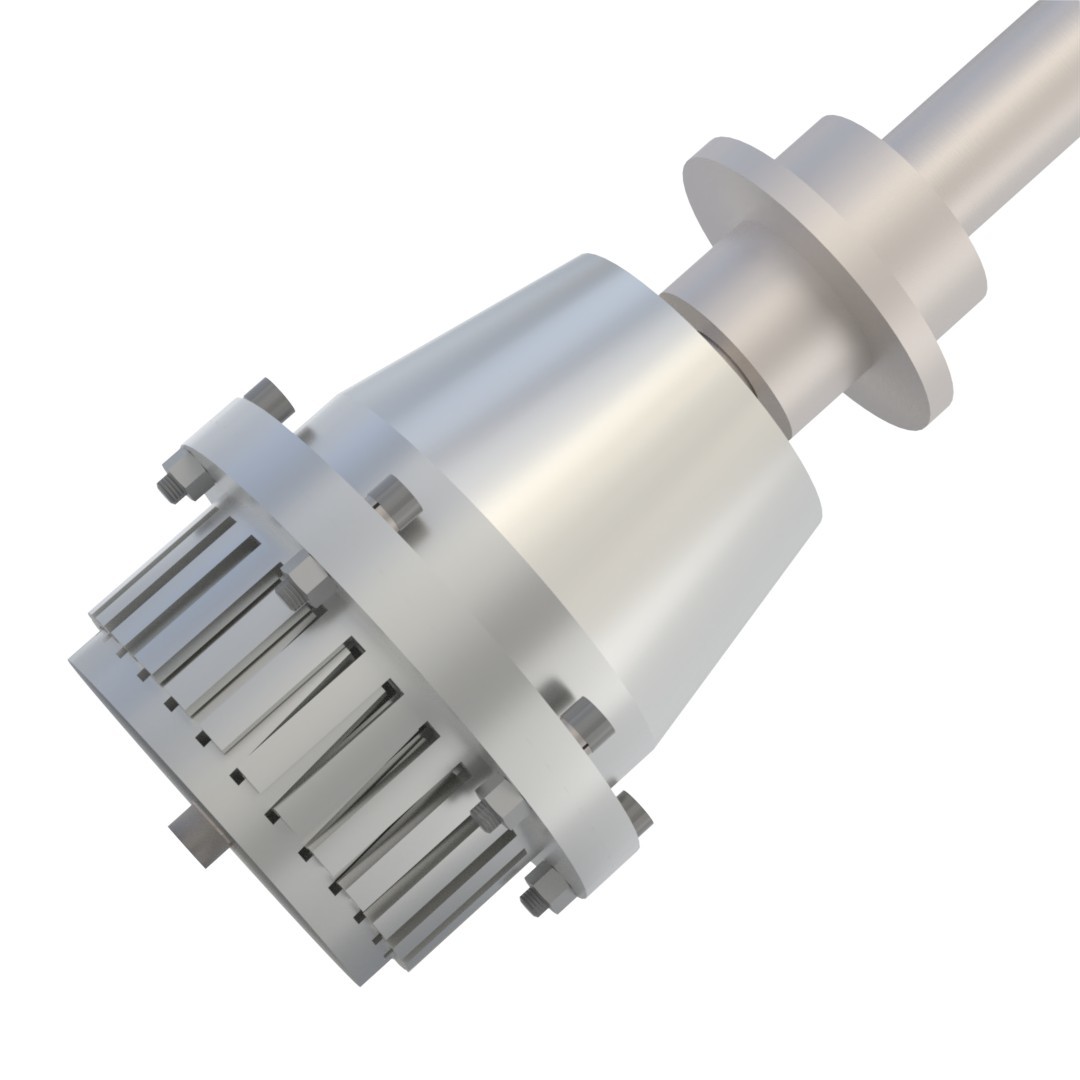

The core components of a high-shear emulsifier are the rotor and stator. Its working process is as follows:

Material suction: The high-speed rotating rotor generates a strong centrifugal force, which sucks the material from the feed area of the working head into the working chamber.

Primary emulsification: Under the action of centrifugal force, the material is thrown into the narrow gap between the stator and the rotor, and is subjected to centrifugal compression, shearing and other forces, thus initially achieving dispersion and emulsification.

Extrusion: The linear velocity at the outer end of the rotor is very high (up to 15 m/s or more, and up to 40 m/s). The material is further refined under the action of strong shearing force and extruded from around the stator slots.

Circulating emulsification: The extruded material changes its flow direction due to the resistance of the inner wall of the container, forming two strong turbulent flows. After multiple cycles, the material is finally dispersed, emulsified and homogenized.

2. Technical Features

High-efficiency shearing: The high-speed relative motion between the rotor and stator generates a strong shearing force, which can rapidly reduce the droplet size and achieve efficient emulsification and dispersion.

Multi-material processing: Suitable for mixing and emulsifying various materials such as liquid-liquid, liquid-solid, and gas-liquid, and also has good processing effect on high viscosity and high concentration materials.

Compact structure: The equipment has a compact structure, is easy to install, operate and maintain.

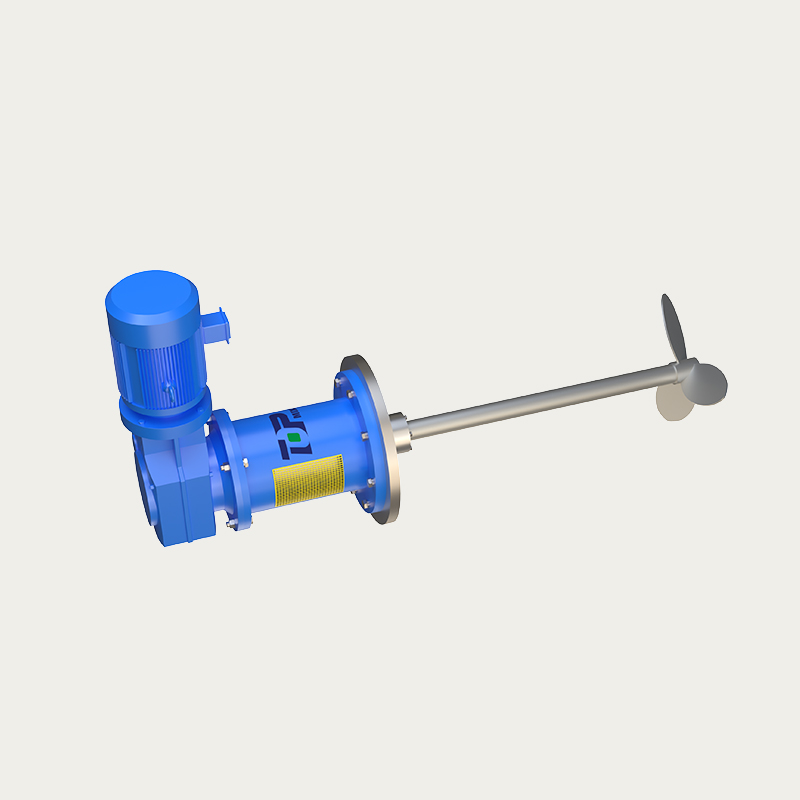

Multiple configurations: Models with different power, speed and installation methods are available to meet different production scales and process requirements.

Material selection: Parts that come into contact with materials are usually made of corrosion-resistant materials such as 304 or 316L stainless steel to ensure the durability of the equipment and the hygiene and safety of the materials.

3. Application Areas

Food industry: Used in the production of dairy products, beverages, seasonings, etc., to improve product stability and taste.

Chemical industry: Used in the production of coatings, adhesives, fine chemicals, etc., enabling uniform mixing and dispersion of materials.

Pharmaceutical industry: Used in the preparation of ointments, emulsions, suspensions, etc., to ensure the uniform distribution of drug components.

In the cosmetics industry: it is used to produce lotions, creams, serums, etc., and can improve the stability and effectiveness of the products.

High-shear emulsifiers, with their high efficiency, flexibility and reliability, have become an indispensable piece of equipment in modern industrial production, significantly improving production efficiency and product quality.

English

English