-

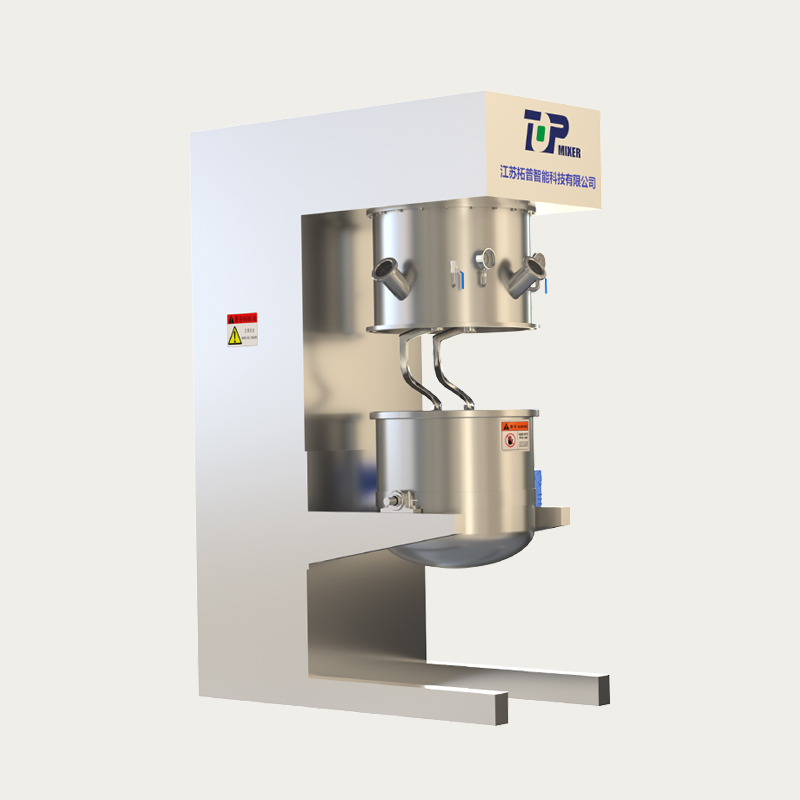

TOP2003 SL Double Helix Cone Mixer

TOP2003 SL Double Helix Cone Mixer

The double helix conical mixer is a new type of mixing equipment with high uniformity, low energy consumption, low residue, and low crushing. The device consists of two asymmetric spirals. While rotating around the axis, they rotate around the axis and use the rotation action of the rotating arm to make revolutions in the cone. The material is repeatedly lifted through the male and self-rotation of the spirals and finally achieves the purpose of mixing evenly. This product has a wide range of applications and can mix powder, powder, and liquid, and can easily stir fine powder, fiber, or sheet-like materials: This equipment is one of the earliest developed and applied mixers on the market.

Explore More

-

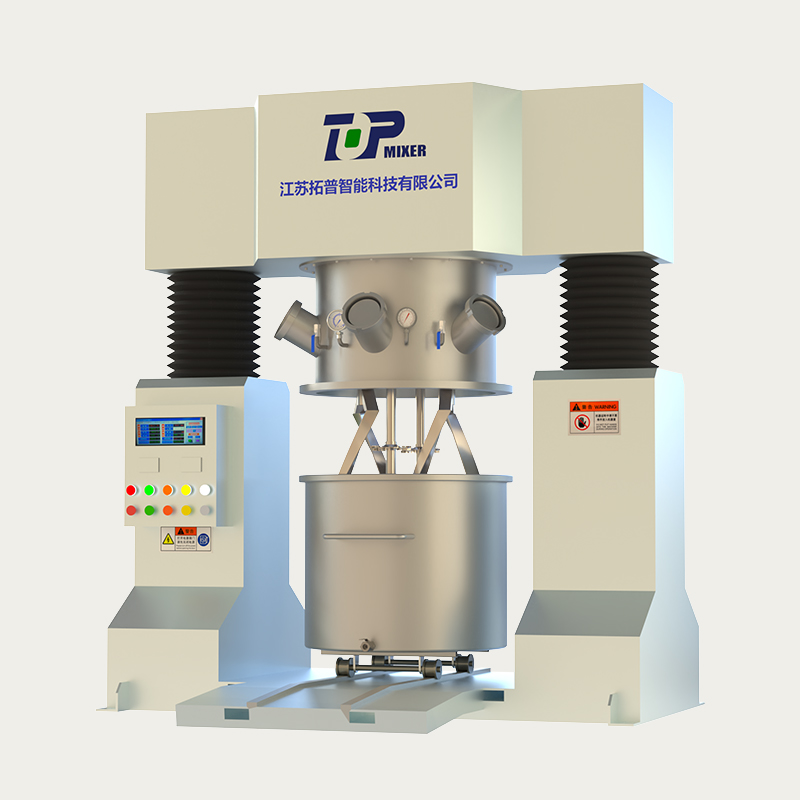

TOPH2011 Series SXJ Experimental Double Planetary Mixer

TOPH2011 Series SXJ Experimental Double Planetary Mixer

Laboratory dual-planetary mixer is a new and efficient mixer developed by Top Company in response to the needs of colleges and universities, research units, and factory laboratories. Suitable for dispersion and mixing of solid-liquid and liquid-liquid phases; suitable for products with high viscosity, such as adhesives, silicone, and lithium battery slurry; at the same time, the equipment has a wall scraping function, no dead corners, and no residue; the equipment is equipped with an extrusion device and sliding guide rail to realize integrated stirring and discharge operations.

Explore More

-

TOPH2012 Series ZXJ Pilot Planetary Mixer

TOPH2012 Series ZXJ Pilot Planetary Mixer

The ZXJ medium-pilot planetary mixer is a new and efficient chemical homogeneous mixing equipment. It has a great output torque and is especially suitable for very thorough mixing of materials with medium and high viscosity and high thixotropy (such as adhesives, silicone, lithium battery paste, etc.).

This machine adopts innovative technologies such as a unique blade design, advanced stirring mode, and transmission principles. The mixing paddle and the dispersion shaft rotate at the same time, and there is no dead corner of the stirring. The material rolls up and down and horizontally at high speeds. The dispersion plate continuously shears and disperses the material, and the material can achieve a uniform effect in a very short time.

Explore More

-

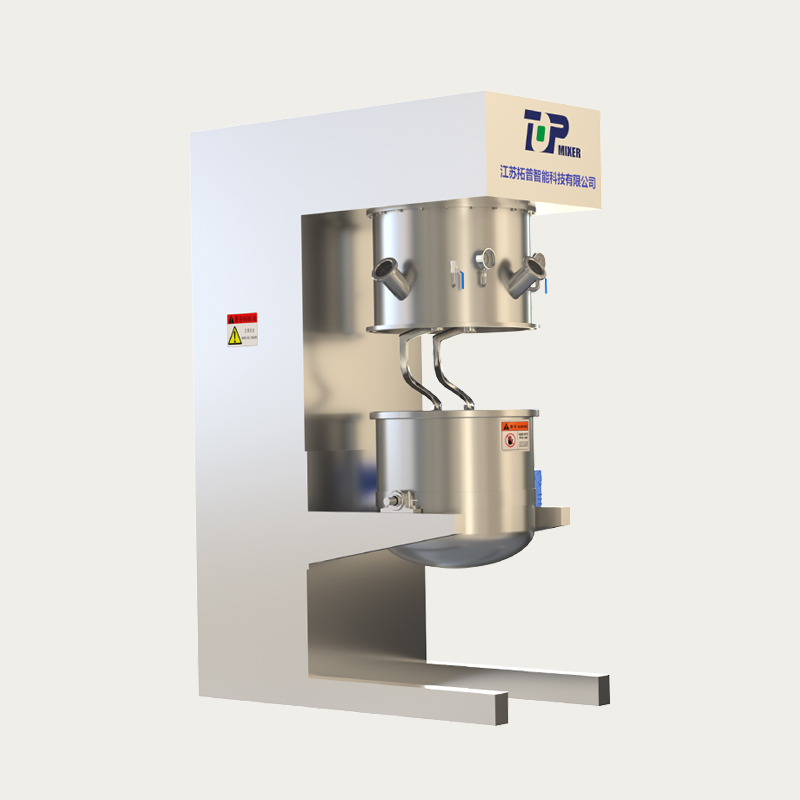

TOPH2013 Series GXJ Industrial Double Planetary Mixer

TOPH2013 Series GXJ Industrial Double Planetary Mixer

GXJ-type industrial dual planetary mixer is a new mixing equipment with high performance, high efficiency, and ease of cleaning and maintenance. The double-group agitator of this equipment rotates around the axis while rotating. The agitator form is selected according to the viscosity and process characteristics of the material. Common ones include blade type, twist type, claw type, frame type, etc., which have good mixing, reaction, dispersion, and dissolution effects. The high-speed disperser consists of multiple layers of serrated dispersion discs with extremely high linear speed. It also rotates around the axis while rotating at high speed. It can quickly disperse powder (adjusting agent) to the slurry force and has a strong dispersion effect. The dual-planetary power mixing mixer is equipped with a set of independent scrapers, which are constantly scraped against the wall of the barrel. At the same time, the stirring paddle can add scrapers and be arranged at the bottom of the barrel for scraping, avoiding stirring dead corners, ensuring the stability of the product, and improving the mixing effect. Its transmission adopts planetary wheel transmission, with large output torque, and is suitable for high-temperature, high-solidity, high viscosity, and other high-difficulty conditions. The machine is designed with a closed design, which can be used to match a vacuum system to realize vacuum stirring. The mixing barrel can be designed with jacket heating, and a mold temperature machine to realize a constant temperature stirring function. It is the choice for dispersion and stirring equipment for high-viscosity materials on the market.

Explore More

-

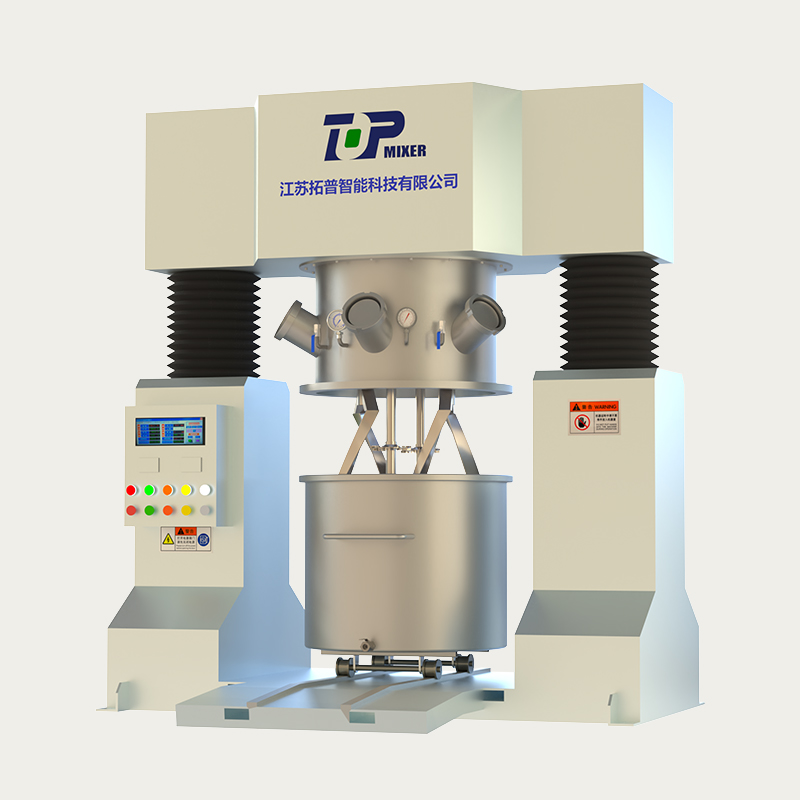

TOPH2014 Series LGXJ Industrial Double Planetary Mixer

TOPH2014 Series LGXJ Industrial Double Planetary Mixer

LGXJ Dual Planet Powered Mixer is a new mixing equipment developed by Top Company on the basis of the GXJ Dual Planet Mixer, which is specially developed for the lithium battery industry with high performance, high efficiency, and easy cleaning and maintenance. In addition to the characteristics of the GXJ mixer, this equipment also has the characteristics of a high sanitary level, convenient operation, and high intelligence.

Explore More

-

TOPH2021 Series ZG Pilot Planetary Mixer

TOPH2021 Series ZG Pilot Planetary Mixer

During the working process of the 21 series ZG type pilot planetary mixer, two parallel mixing pads operate in a fixed rotation ratio set, and rotate quickly along the mixing drum. At the same time, there is a rotating scraper that operates simultaneously with the revolution in the mixing drum, which keeps rotating, so that the material moves from the inner wall of the mixing drum to the vicinity of the mixing pad. The direction of the mixer can be reversible in the same direction and reversible in order to achieve different shearing purposes. The other two high-speed dispersed gear discs of separate power units also operate along the mixing barrel along with the rotation, performing efficient dispersion, emulsification, and high-speed dispersed gear discs to be variable frequency speed regulation, and can be customized according to the production process.

This type of movement can enable the material to achieve a completely uniform emulsification and mixing effect in a short time and is especially suitable for the dispersion and mixing of solid-solid phase, solid-liquid phase, and liquid-liquid phase.

Explore More

-

TOPH2022 Series GG Industrial Planetary Mixer

TOPH2022 Series GG Industrial Planetary Mixer

The 22 Series GG industrial planetary mixer is a new and efficient mixing equipment. The mixing paddle rotates around the axis of the kettle body while rotating around its own axis so that the materials can be fully mixed in the kettle; the 22 Series GG industrial planetary mixer has good mixing, stirring, reaction, dispersion ,and dissolution, and is especially suitable for solid-solid and solid-liquid mixing. At the same time, the equipment also has a wall scraping function, which ensures no dead corners and no residues during the entire equipment operation. There are many forms of stirring paddles, and the contact material part can be sprayed with ceramic materials (zirconia/tungsten carbide/Teflon, etc.). Reduces metal ion pollution.

Explore More

-

TOPH2031 Series V-Type Vacuum Ribbon Mixer

TOPH2031 Series V-Type Vacuum Ribbon Mixer

Product Advantages

1. Frequently displace and stir the free-flow solid material.

2. Cantilever shaft structure, the bearing end does not come into contact with the material.

3. The gap between the stirring slurry and the container wall is very small to prevent the material from being bonded.

4. Standardized stirring drive box to ensure stable operation and low maintenance costs.

5. O-rings with special geometric shapes, high-quality equipment surface treatment and eliminate blind spots.

6. The container can be heated or cooled by an outer jacket (optional).

7. The crusher is used to prevent material from agglomerating.

Explore More

-

TOPH2032 Series SL Double Helix Conical Mixer

TOPH2032 Series SL Double Helix Conical Mixer

The 32 series double helix conical mixer is a new type of mixing equipment with high homogeneity, low energy consumption, low residue, and low crushing. The equipment is equipped with two asymmetric spirals. While rotating around the axis, they rotate around the axis and use the rotation action of the rotating arm to make revolutions in the cone. The material is repeatedly lifted through the male and self-rotation of the spirals to finally achieve the purpose of mixing evenly. This product has a wide range of applications and can mix powder and powder, powder and liquid, and can stir fine powder, fiber, or sheet-like materials.

Explore More

English

English