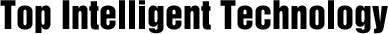

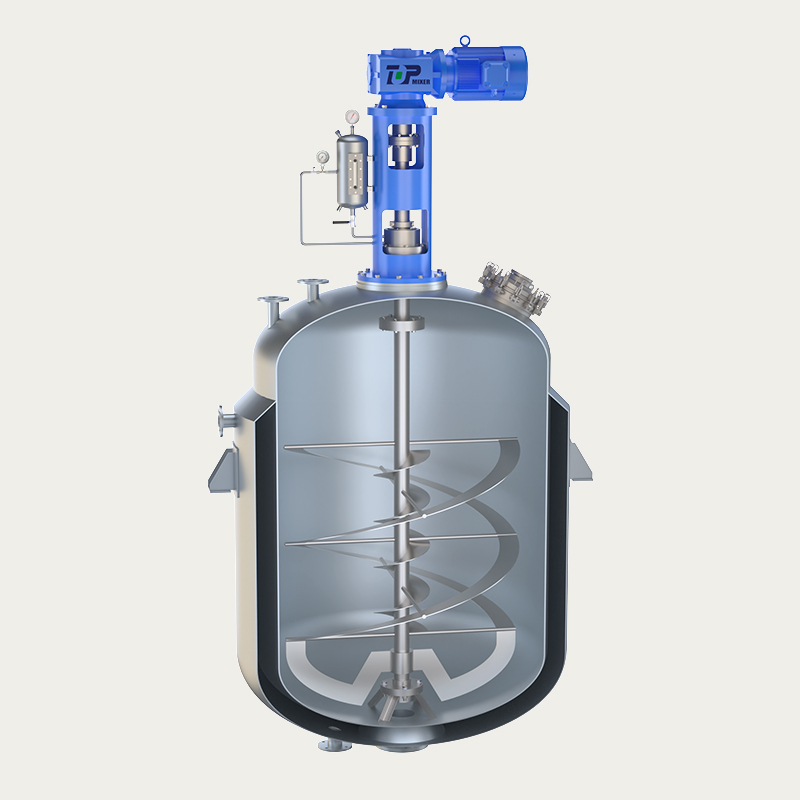

TOP2003 SL Double Helix Cone Mixer

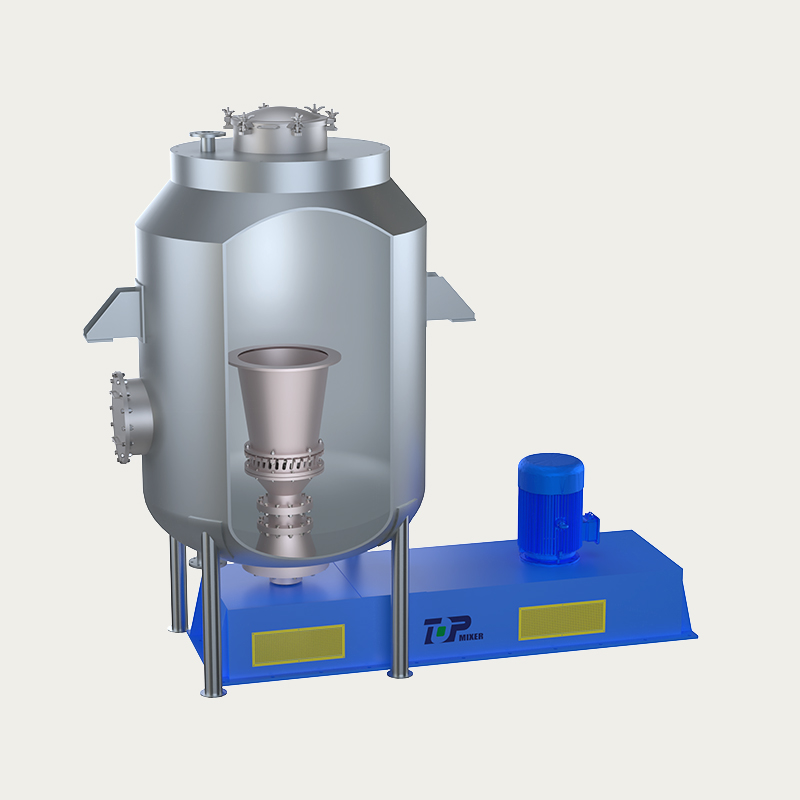

The double helix conical mixer is a new type of mixing equipment with high uniformity, low energy consumption, low residue, and low crushing. The device consists of two asymmetric spirals. While rotating around the axis, they rotate around the axis and use the rotation action of the rotating arm to make revolutions in the cone. The material is repeatedly lifted through the male and self-rotation of the spirals and finally achieves the purpose of mixing evenly. This product has a wide range of applications and can mix powder, powder, and liquid, and can easily stir fine powder, fiber, or sheet-like materials: This equipment is one of the earliest developed and applied mixers on the market.

Advantages of double helix conical mixer

1. Rich application experience and extremely targeted non-standard design capabilities.

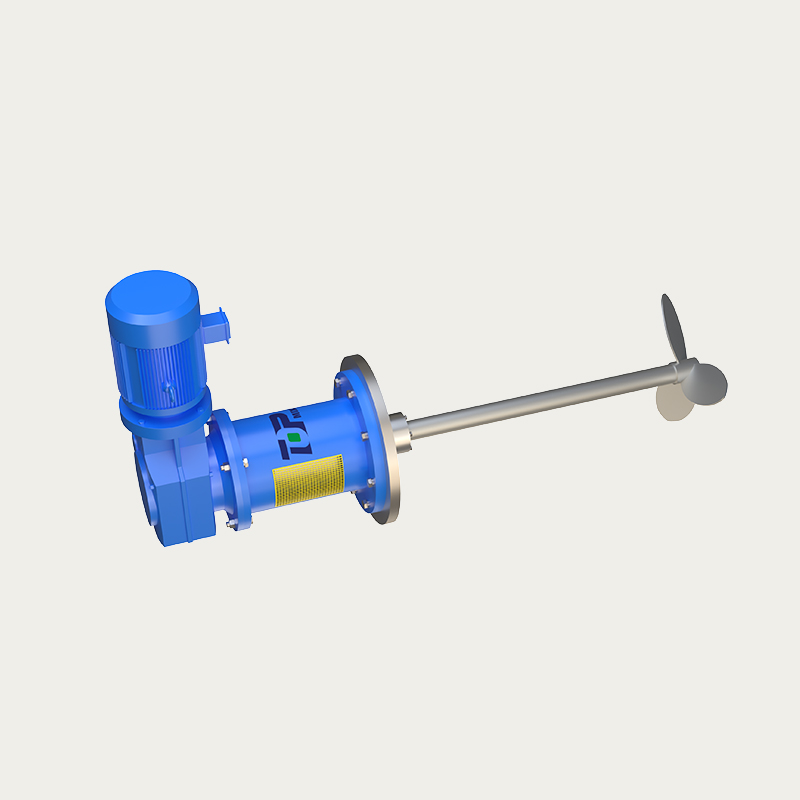

2. Reliable driving configurations are configured to configure drive devices with different capabilities, different powers, and different output speeds according to the material properties, starting methods, and stirring methods. Drive motors use international first-class motor suppliers products, such as Siemens, ABB, SEW and other reducers commonly used cycloidal pinwheel speed machines or turboworm reducers. For liquid spraying types, they can use a combined structure of hard-toothed reducer and cycloidal pinwheel reducer (materials are sprayed in from the middle, which has a better effect).

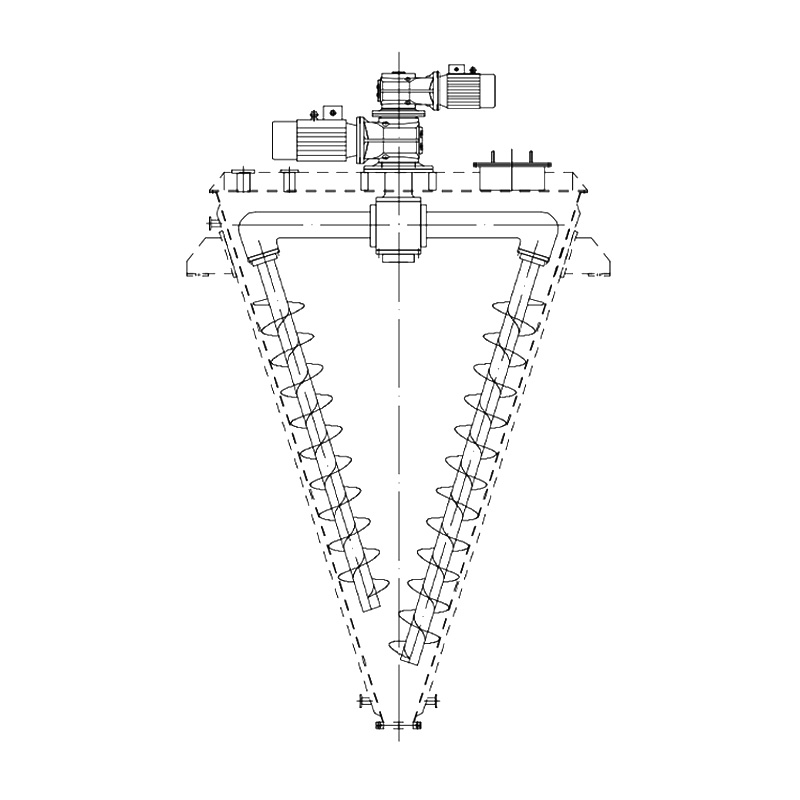

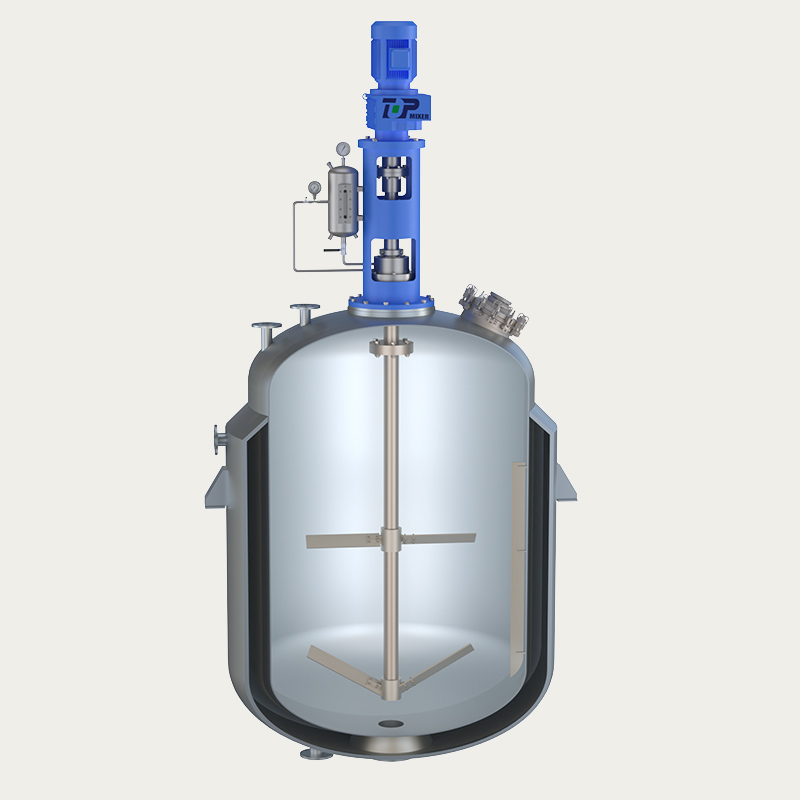

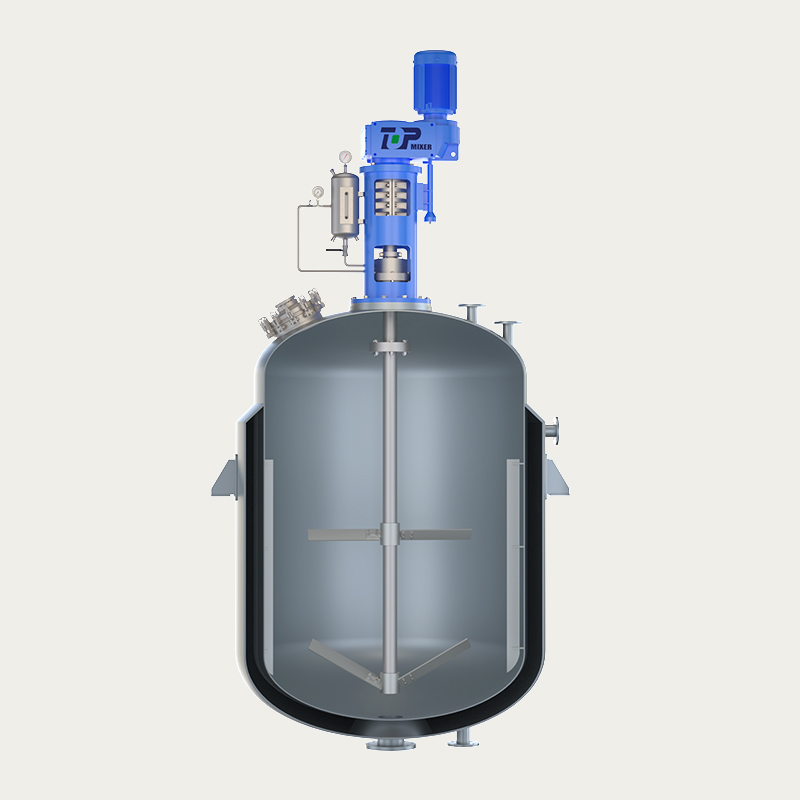

3. Powerful auxiliary components. The mixer can be equipped with a variety of components, commonly used including coil steam jackets, honeycomb pressure-resistant jackets, circulating media jackets, online sampling valves, temperature detection, weighing systems, dust purification, and other components.

4. When adding a small amount of liquid, a liquid spraying device needs to be installed, which is more conducive to the uniform dispersion and mixing of the liquid in the main material. The liquid spraying system consists of three basic modules: pressure source, liquid storage tank, and spray head. All functional non-standard products can be customized, such as liquid spray type, explosion-proof type, heating type, vacuum type, etc. The materials can be customized according to requirements, carbon steel, SS304 stainless steel, SS316L stainless steel, SS321 stainless steel, or polyurethane lining or spraying high-wear-resistant materials.

Valves can be customized with plum blossom valves, butterfly valves, gate valves, ball valves, etc.

Working principle of double-helix conical mixer The double-helix conical mixer consists of a transmission part, a screw stirrer, and an inverted conical barrel. The stirrer has two asymmetric spirals. While rotating around the axis, they rotate around the axis and use the rotation of the rotating arm to make revolutionary movements in the cone. The equipment repeatedly lifts the material through the male and self-rotation of the spiral, and produces composite movements such as shear, convective diffusion, and other complex movements in the cone, thereby achieving the purpose of uniform mixing.

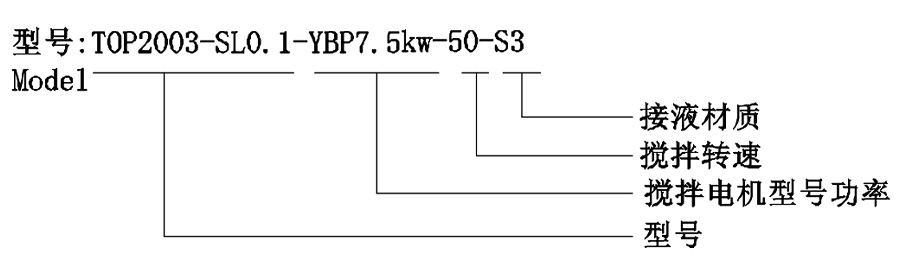

| Model(TYPE) | Full volume(L) | Load factor | Motor (kW) | Sizor (kW) | Weight(kg) | Operation conditions |

| TOP2003-SL0.1 | 0.1 | 0.6 | 1.5 | 1569 ∅ 702 | 250 |

Normal temperature Regular pressure |

| TOP2003-SL0.3 | 0.3 | 0.6 | 2.2 | 1929 ∅ 920 | 550 | |

| TOP2003-SL0.5 | 0.5 | 0.6 | 3 | 2322 ∅ 1124 | 660 | |

| TOP2003-SL1.0 | 1 | 0.6 | 4 | 2869 ∅ 1480 | 1200 | |

| TOP2003-SL1.5 | 1.5 | 0.6 | 5.5 | 3140 ∅ 1633 | 1350 | |

| TOP2003-SL2 | 2 | 0.6 | 5.5 | 3489 ∅ 1816 | 1500 | |

| TOP2003-SL3 | 3 | 0.6 | 7.5 | 3747 ∅ 2210 | 2300 | |

| TOP2003-SL5 | 5 | 0.6 | 11 | 4576 ∅ 2402 | 3000 | |

| TOP2003-SL8 | 8 | 0.6 | 15 | 5405 ∅ 2805 | 4500 | |

| TOP2003-SL10 | 10 | 0.6 | 18.5 | 5795 ∅ 3018 | 5500 | |

| TOP2003-SL15 | 15 | 0.6 | 22 | 6475 ∅ 3450 | 6600 | |

| TOP2003-SL20 | 20 | 0.6 | 30 | 7535 ∅ 3805 | 7000 |

English

English