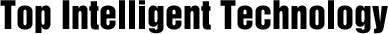

TOPH2014 Series LGXJ Industrial Double Planetary Mixer

LGXJ Dual Planet Powered Mixer is a new mixing equipment developed by Top Company on the basis of the GXJ Dual Planet Mixer, which is specially developed for the lithium battery industry with high performance, high efficiency, and easy cleaning and maintenance. In addition to the characteristics of the GXJ mixer, this equipment also has the characteristics of a high sanitary level, convenient operation, and high intelligence.

Material Viscosity: ≤3000000cps

Production Capacity: 5-2000L

Application Field: Suitable for dispersing and mixing materials in coatings, putty, inks, adhesives, energy, electronics and electrical appliances, pharmaceuticals, cosmetics, food, and other industries.

Applicable Materials: Various slurries with material viscosity below 3000000cps and solid content below 90%.

Product Advantages

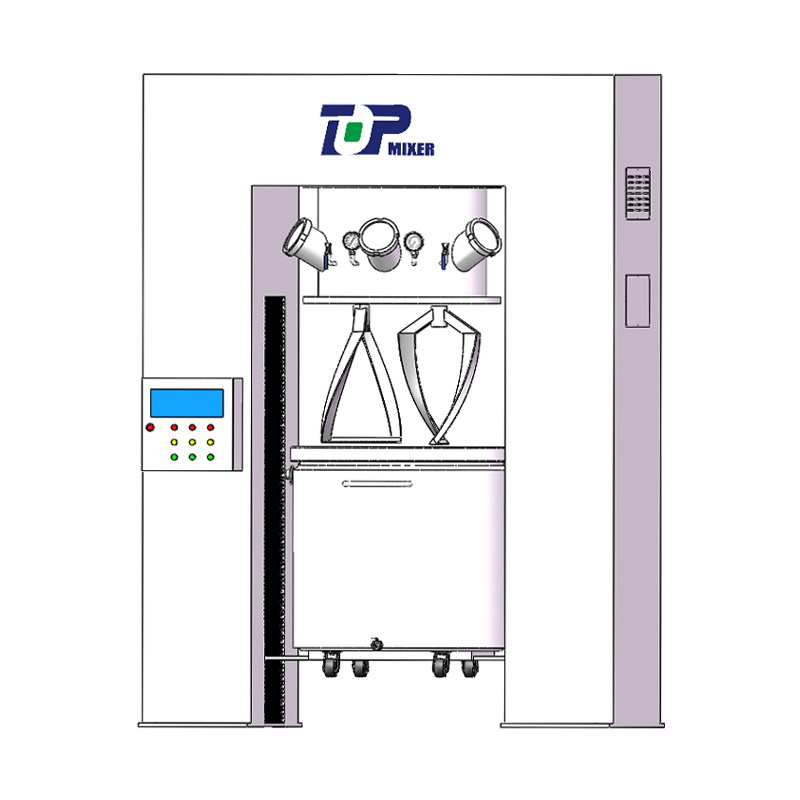

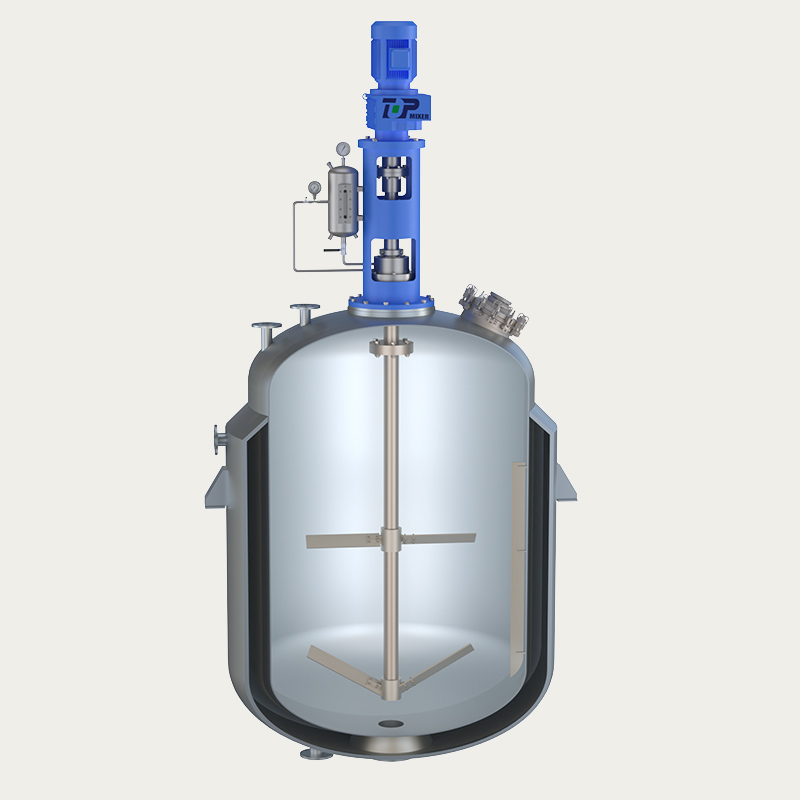

High stirring efficiency and wide application range

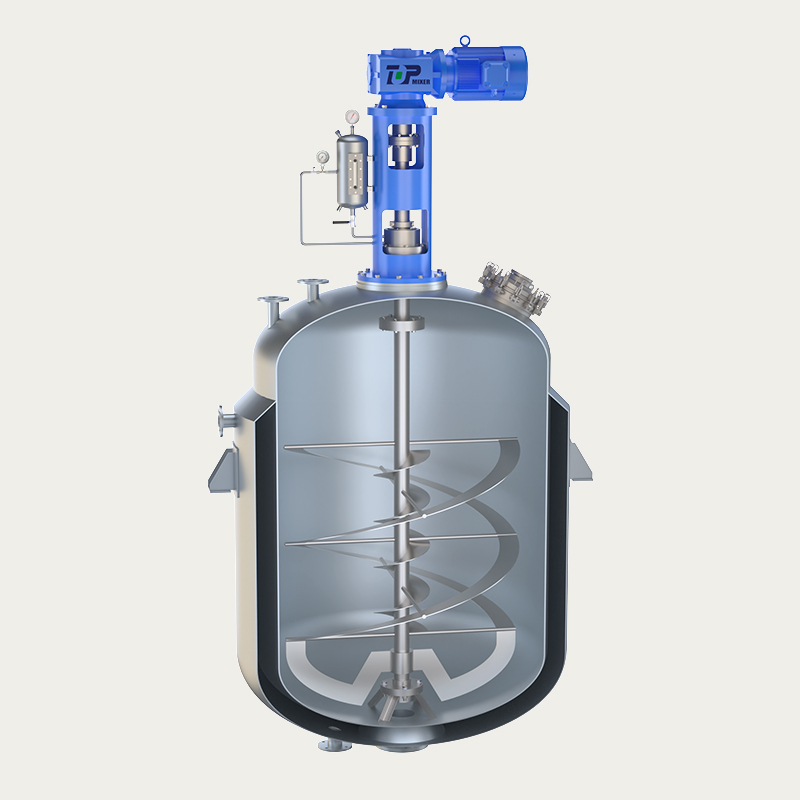

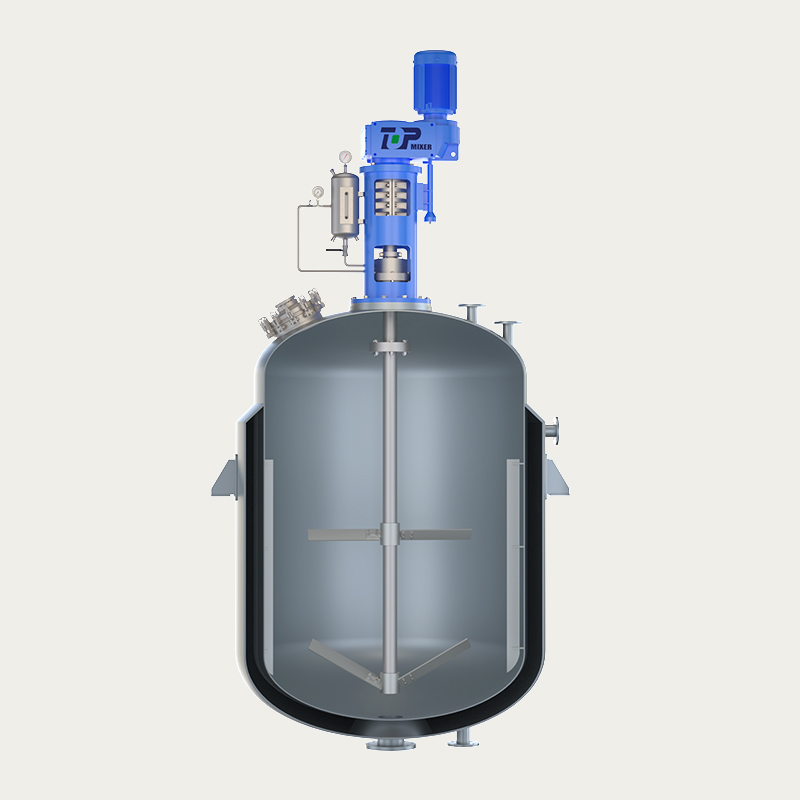

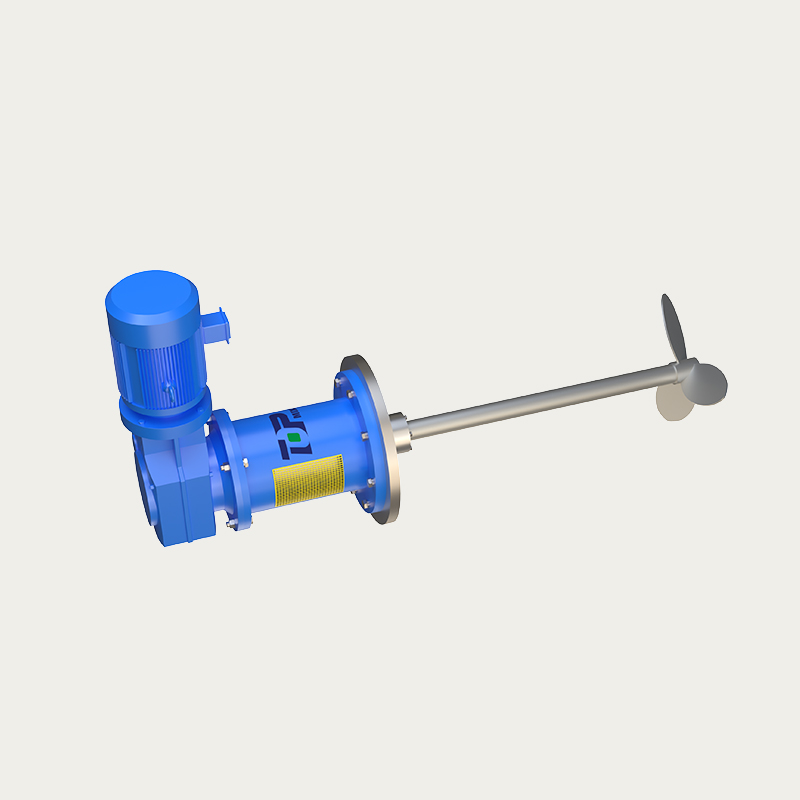

The dual-planetary power mixer has two sets of stirring paddles and a set of high-speed dispersion shafts rotating around the barrel axis at high speed, so that the material is subject to strong shearing and kneading, achieving the purpose of rapid mixing; the stirring paddles are available in various forms such as blade type, twist type, melon type, frame type, etc. The best stirring form can be selected for materials with different viscosity specific gravity and different production process requirements.

Easy to operate and safe

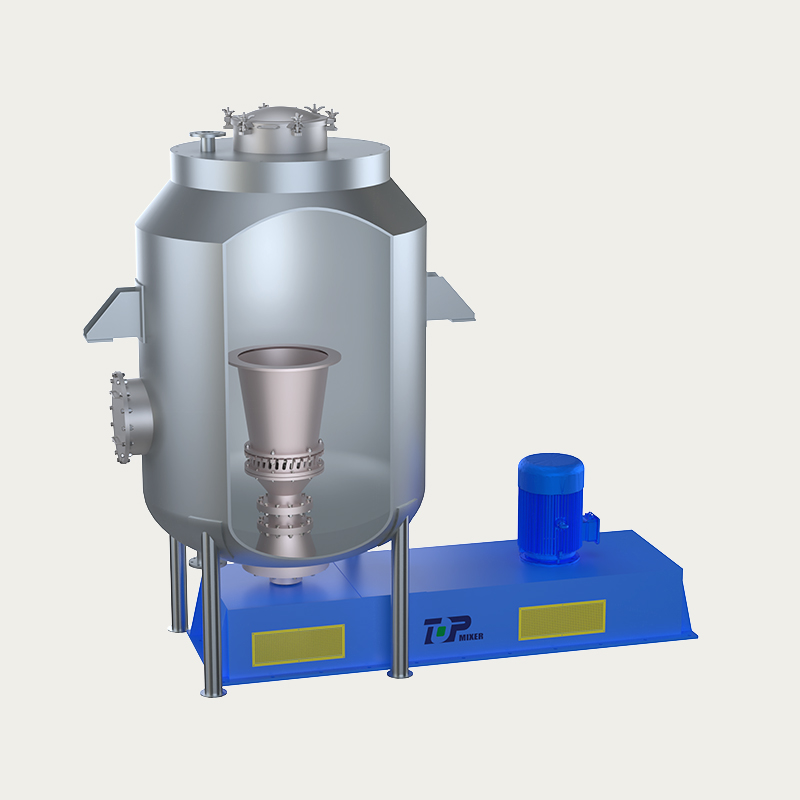

The equipment is used as a lifting actuator through the oil cylinder. The lifting adopts the bottom lifting method, that is, the agitating device is fixed, and the operation is achieved through the lifting of the material barrel. The lifting device has a material barrel fixing device, which can prevent the barrel from being displaced during work and causing safety accidents. At the same time, a slide rail device is provided between the agitating and extrusion to facilitate material movement and realize integrated stirring and discharge operations.

The material does not stick to the wall, the discharge is clean

There is a scraper on the planet carrier moving with the planet carrier, constantly scraping against the bucket wall. After the bucket wall is finished stand-alone, it is polished by an automatic polishing machine to ensure that the movable scraper on the planet carrier completely scrapes the barrel wall material when it rotates, so that there is no retained material on the bucket wall, and improves the mixing effect.

| Model | Effective volume(L) | Design volume(L) | Mixing barrel size(mm) | Stirring power(kW) | Rotation speed(rpm) | Rotation speed (rpm) | Dispersed power (kW) | Dispersed speed (rpm) | Linear speed (m/s) |

| TOPH2014-100 | 100 | 150 | ∅650*450 | 15 | 0-34 | 0-56 | 18.5 | 0-2930 | 23 |

| TOPH2014-200 | 200 | 265 | ∅750*650 | 22 | 0-33 | 0-53 | 30 | 0-2750 | 23 |

| TOPH2014-300 | 300 | 370 | ∅850*650 | 30 | 0-33 | 0-53 | 37 | 0-2200 | 23 |

| TOPH2014-500 | 500 | 670 | ∅1000*850 | 37 | 0-28 | 0-47 | 45 | 0-2000 | 23 |

| TOPH2014-650 | 650 | 822 | ∅1100*865 | 45 | 0-28 | 0-47 | 55 | 0-1750 | 23 |

| TOPH2014-900 | 900 | 1390 | ∅1300*1050 | 75 | 0-24 | 0-32 | 75 | 0-1450 | 23 |

| TOPH2014-1200 | 1200 | 2000 | ∅1450*1200 | 90 | 0-18 | 0-28 | 90 | 0-1375 | 23 |

| TOPH2014-1500 | 1500 | 2300 | ∅1500*1300 | 110 | 0-18 | 0-28 | 110 | 0-1375 | 23 |

| TOPH2014-2000 | 2000 | 3000 | ∅1600*1500 | 132 | 0-16 | 0-28 | 132 | 0-1200 | 23 |

English

English