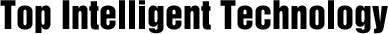

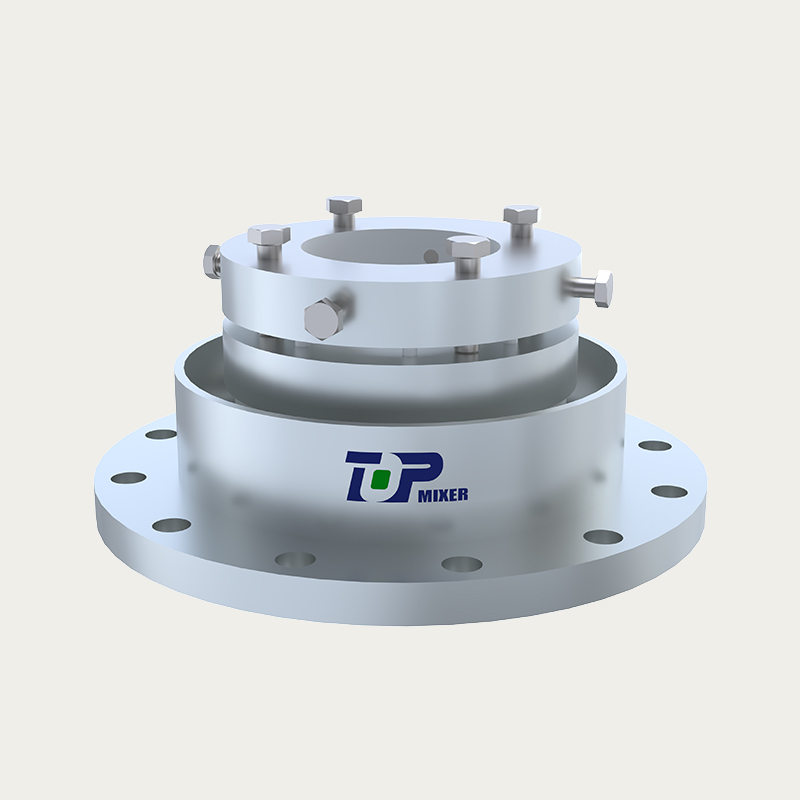

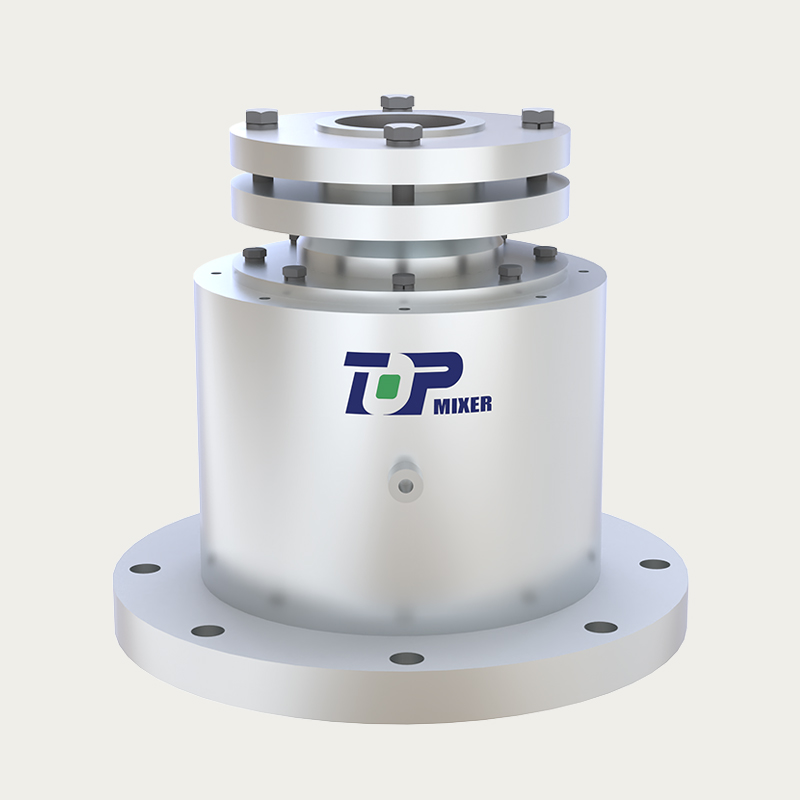

Mechanical Seal

A mechanical seal is a device used to prevent leakage between a rotating shaft and a stationary housing in various machinery. It operates by using a combination of stationary and rotating components, often including a sealing face, spring, and secondary seals, to maintain a tight seal under varying pressures, temperatures, and speeds. Mechanical seals are highly reliable, reduce maintenance needs, and minimize fluid loss, making them essential in modern industries. Commonly used in pumps, mixers, compressors, and agitators, they are widely applied in sectors like oil and gas, chemical processing, water treatment, and power generation. Their ability to handle corrosive, high-temperature, or abrasive fluids ensures enhanced equipment performance and environmental protection, meeting stringent industrial standards.

English

English