-

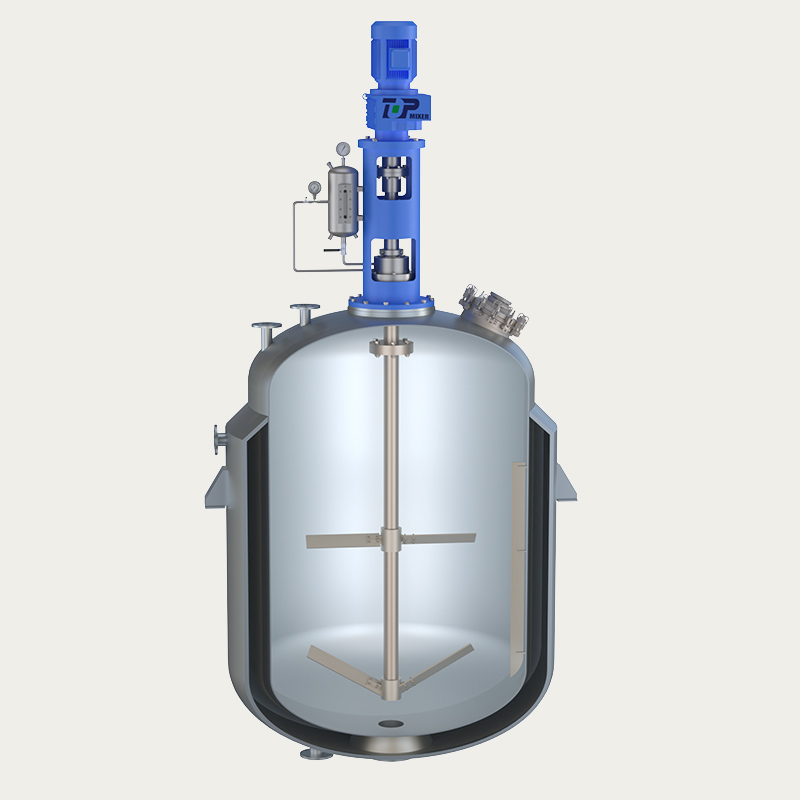

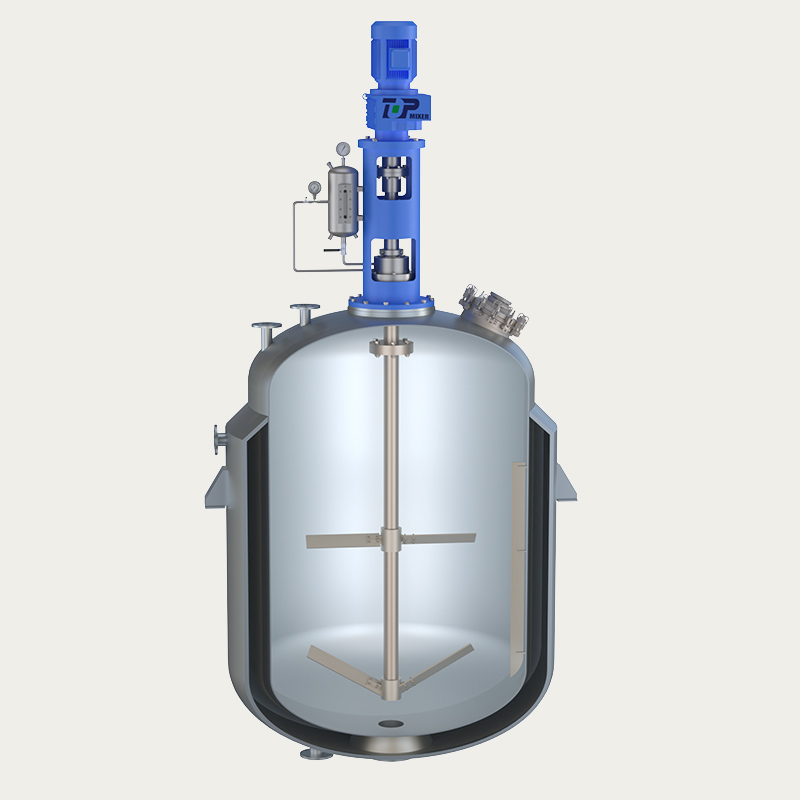

TOPA001DR Top-Entry Mixer

TOPA001DR Top-Entry Mixer

● According to Top's years of experience and unique technology, advanced measurement and analysis technology are applied. Design an efficient impeller with a good mixing effect and use it on our DR mixer.

● Top DR mixer can provide vertical stirring from 0.37KW to 45KW. All products are strictly tested by Top Engineers to ensure the high reliability of the product.

● The mechanical structure is simple and compact, which is easy to operate, maintain, and repair. All the original impeller forms for users are designed to significantly increase the discharge volume.

● A variety of shaft seal types meet different materials and working conditions.

● First motor fixation reduces vibration significantly.

● High-efficient hard-toothed gear transmission, which is heat-resistant and durable. Low noise characteristics.

● Deep groove ball bearing system ensures long-term use without lubrication.

Explore More

-

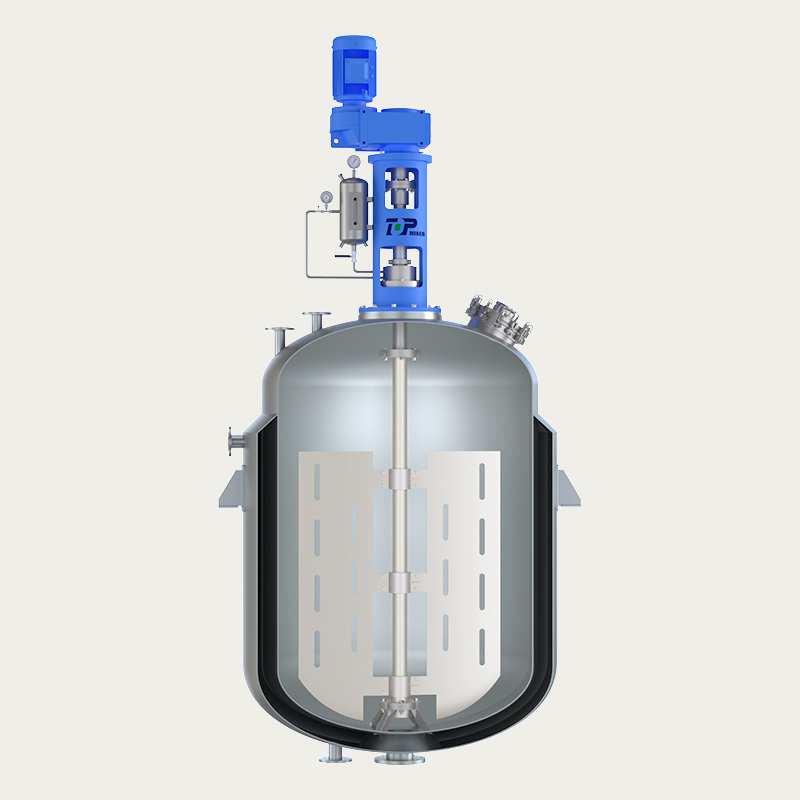

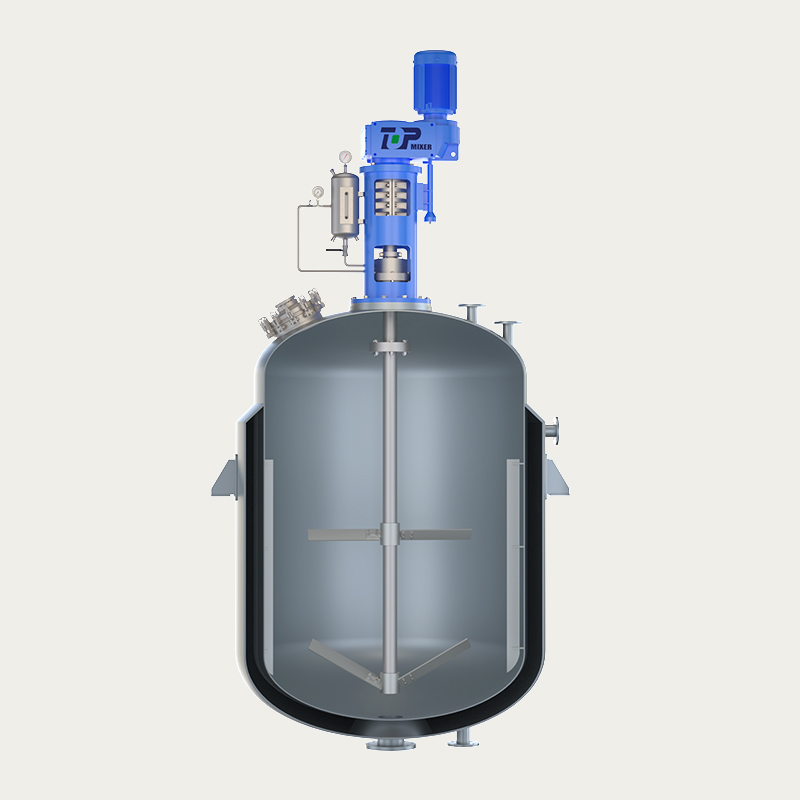

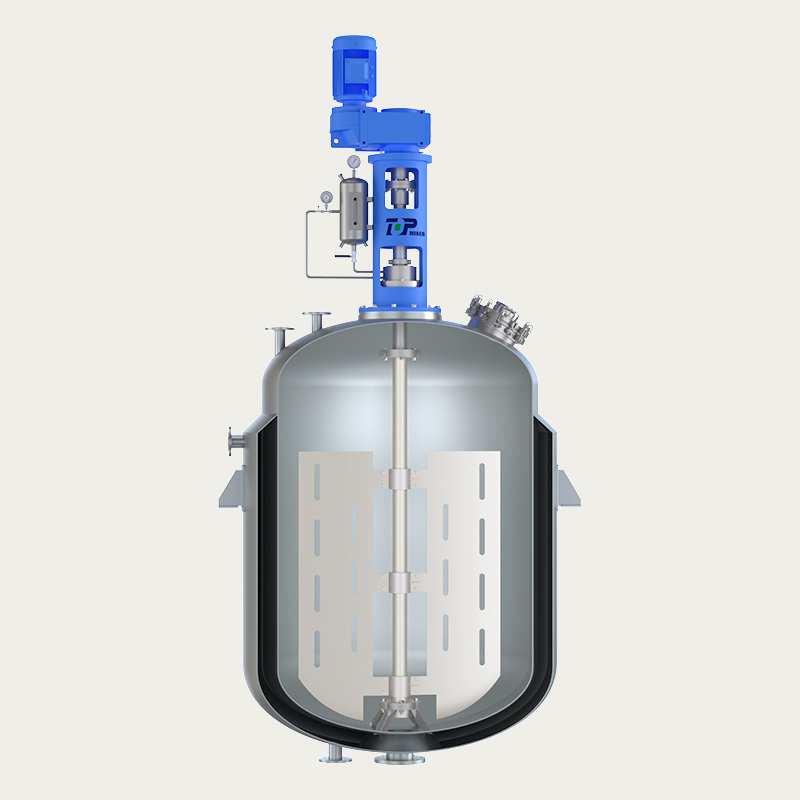

TOPA002 High Viscosity Frame Top-Entry Mixer

TOPA002 High Viscosity Frame Top-Entry Mixer

Based on Top's years of experience with unique technology, and the application of advanced measurement and analysis technology, we designed high-efficiency impellers with good mixing effects and used them on our DL mixers.

● Top DL mixers can provide vertical stirring from 0.37KW to 45KW. All products have been strictly inspected by Top Engineers to ensure the high reliability of the products.

● The mechanical structure is simple and compact, which is easy to operate, maintain, and repair, and everything is for the user's consideration.

● The original impeller form increases the discharge significantly.

● Various shaft seal types meet different materials and working conditions

● Firm motor fixation reduces vibration significantly.

● High-efficiency hard-toothed gear transmission, with the characteristics of heat resistance, durability, and low noise

● Deep groove ball bearing system. Ensure long-term use without lubrication.

Explore More

-

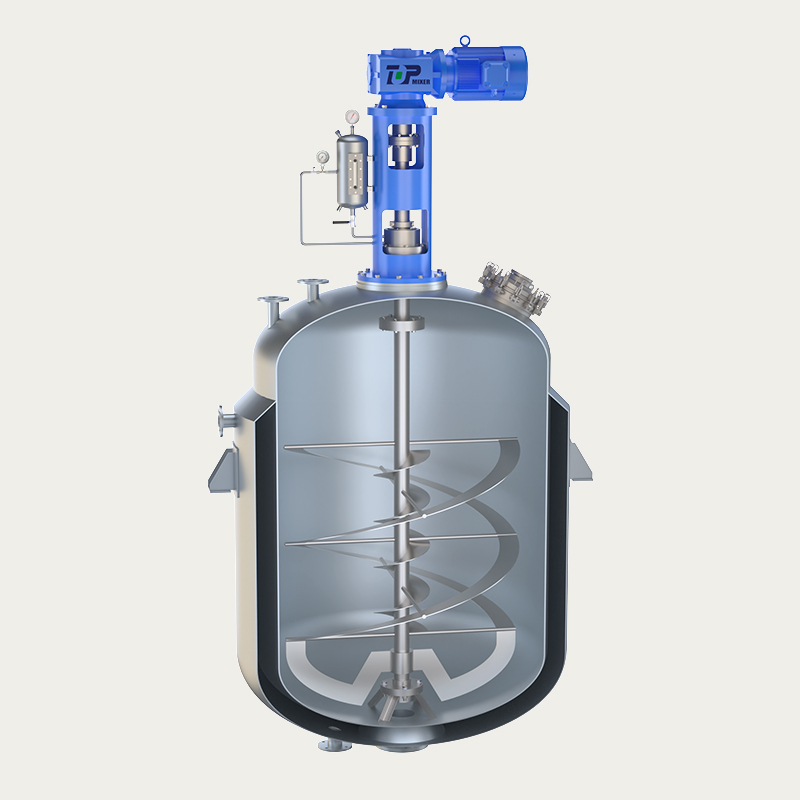

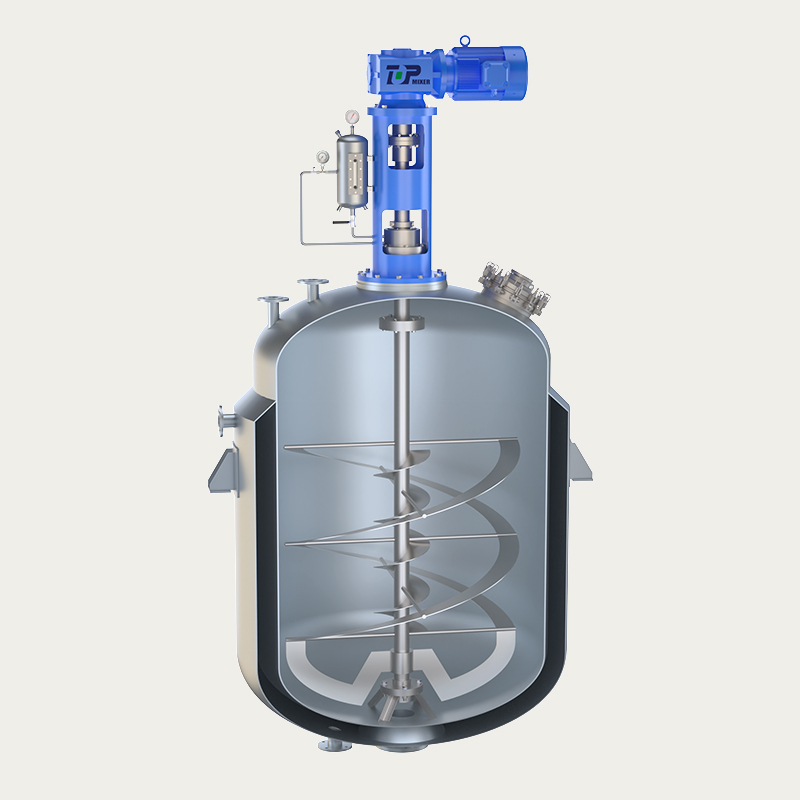

TOPA003 Ribbon Top-Entry Mixer

TOPA003 Ribbon Top-Entry Mixer

Based on Top's years of experience with unique technology, and the application of advanced measurement and analysis technology, we designed high-efficiency impellers with good mixing effects and used them on our DK mixers.

● Top DL mixers can provide vertical stirring from 0.37KW to 45KW. All products have been strictly inspected by Top Engineers to ensure the high reliability of the products.

● The mechanical structure is simple and compact, which is easy to operate, maintain, and repair, and everything is for the user's consideration.

● The original impeller form increases the discharge significantly.

● Various shaft seal types meet different materials and working conditions

● Firm motor fixation reduces vibration significantly.

● High-efficiency hard-toothed gear transmission, heat-resistant and durable, Low noise characteristics

● Deep groove ball bearing system. Ensure long-term use without lubrication.

Explore More

-

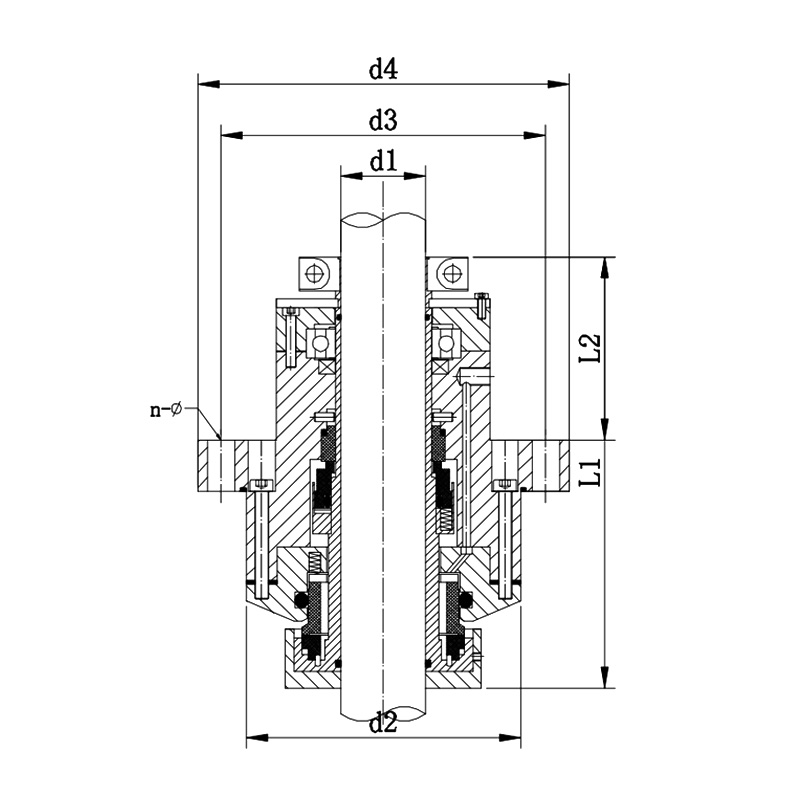

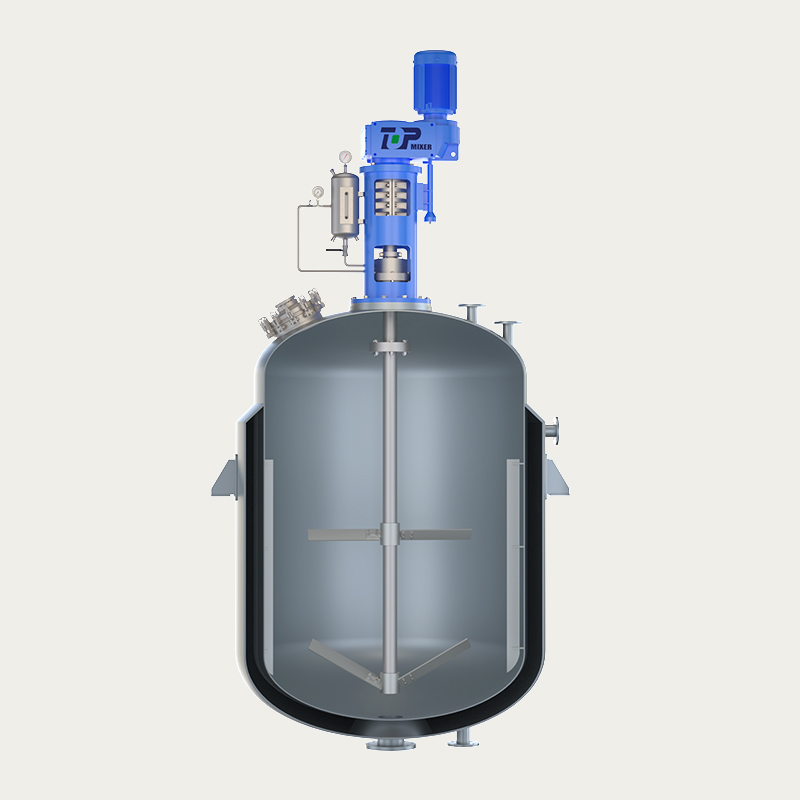

TOPA004 Online Replacement of Mechanical Seal Top-Entry Mixer

TOPA004 Online Replacement of Mechanical Seal Top-Entry Mixer

Based on Top's years of experience and unique technology, the application of advanced measurement and analysis technology is used on our DF mixer.

● Top DL mixers can provide vertical stirring from 0.37KW to 45KW. All products have been strictly inspected by Top Engineers to ensure the high reliability of the products.

● The mechanical structure is simple and compact, which is easy to operate, maintain and repair and everything is for the user's consideration.

● The original impeller form increases the discharge volume significantly.

● Replace several types of seals online to meet different materials and working conditions

● First motor fixation reduces vibration significantly.

● High-efficient hard-toothed gear transmission, with the characteristics of heat resistance, durability, and low noise.

● Deep groove ball bearing system. Ensure long-term use without lubrication.

Explore More

-

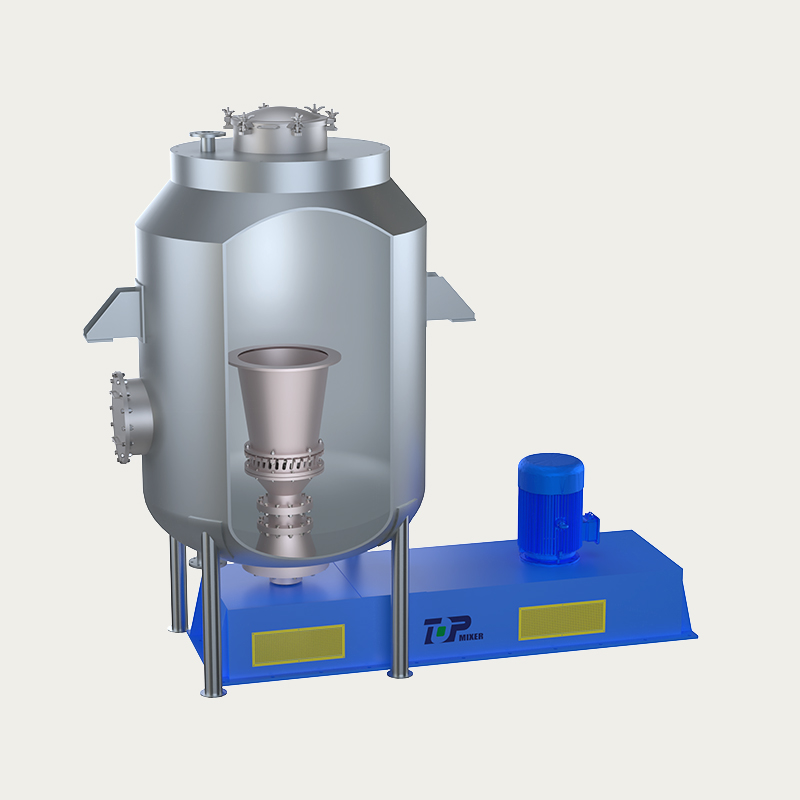

TOPA005 FS1 Series High Speed Disperser

TOPA005 FS1 Series High Speed Disperser

Based on Top's years of experience and unique technology and the application of advanced measurement and analysis technology, we designed high-efficiency impellers with good mixing effects and used them on our high-speed dispersive mixers.

● Top high-speed dispersing mixer can provide vertical stirring from 1.1KW to 90KW. All products are strictly inspected by Top engineers to ensure the high reliability of the product.

● The mechanical structure is simple and compact, which is easy to operate, maintain, and repair, and everything is for the user's consideration.

● The original impeller form increases the discharge volume significantly.

● A variety of shaft seal types meet different materials and working conditions.

● First motor fixation reduces vibration significantly.

● High-efficient hard-toothed gear transmission, which is heat-resistant, durable, and low noise.

● Deep groove ball bearing system ensures long-term use without lubrication.

Explore More

-

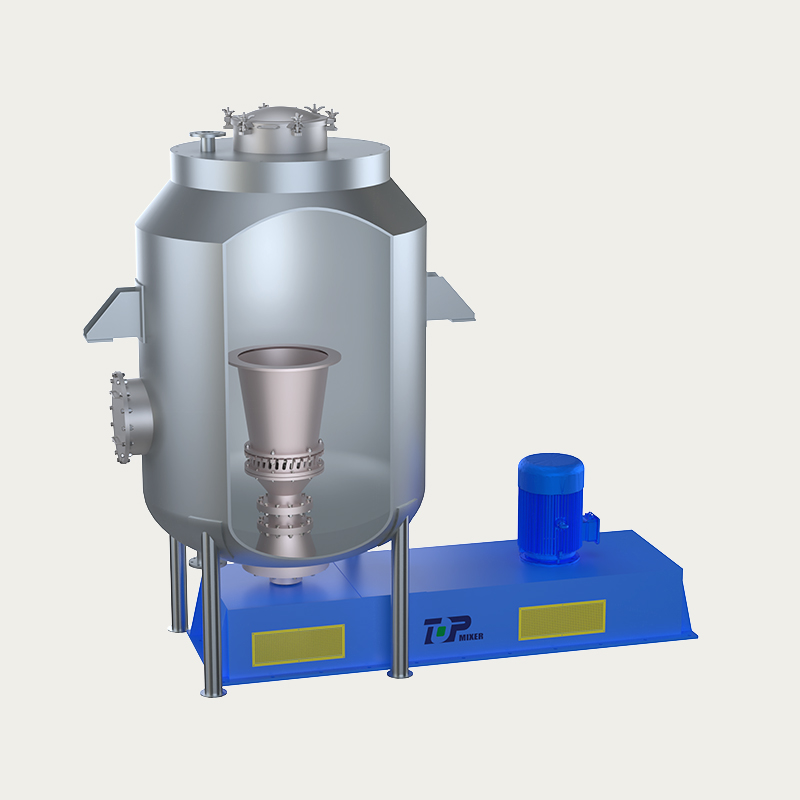

TOPA006 ZX1 Series Central Control Heat Exchange Top-Entry Mixer

TOPA006 ZX1 Series Central Control Heat Exchange Top-Entry Mixer

● Based on Top's years of experience and unique technology and the application of advanced measurement and analysis technology, we designed an efficient impeller with an good mixing effect and used it on our FAF mixer.

● Top self-priming mixer can provide vertical stirring from 1.1KW to 45KW. All products are strictly inspected by Top engineers to ensure the high reliability of the product.

● The mechanical structure is simple and compact, which is easy to operate, maintain, and repair, and is for the sake of users.

● The original impeller form increases the discharge volume significantly.

● A variety of shaft seal types meet different materials and working conditions.

● First motor fixation reduces vibration significantly.

● High-efficient hard-toothed gear transmission, which is heat-resistant, durable, and low noise.

● Deep groove ball bearing system ensures long-term use without lubrication.

Explore More

-

TOPA007 TX1 Series Concentric Double Speed Top-Entry Mixer

TOPA007 TX1 Series Concentric Double Speed Top-Entry Mixer

The SS series two-speed mixer uses medium and high-speed stirring in the middle, and the edge extension uses low-speed stirring. It is usually used in medium and high-viscosity occasions and is suitable for Newtonian and non-Newtonian fluids. It has the characteristics of sufficient and even stirring of materials.

● The intermediate stirring speed and the Yanbian stirring speed can be determined according to the specific material characteristics of the customer.

Explore More

-

TOPA008 FJ1 Series Large Fermentation Tank Top-Entry Mixer

TOPA008 FJ1 Series Large Fermentation Tank Top-Entry Mixer

● Based on Top's years of experience and unique technology and the application of advanced measurement and analysis technology, we designed an efficient impeller with a good mixing effect and used it on our SFJ mixer.

● Top FJ mixer can provide vertical stirring from 65KW to 320KW. All products are strictly inspected by Top Engineers to ensure the high reliability of the product.

● The mechanical structure is simple and compact, which is easy to operate, maintain, and repair, and everything is for the user's consideration.

● The original impeller form increases the discharge volume significantly.

● A variety of shaft seal types meet different materials and working conditions.

● First motor fixation reduces vibration significantly.

● High-strength V-type pulley transmission, with the characteristics of stable and reliable operation and long service life.

● Deep groove ball bearing system ensures long-term use without lubrication.

Explore More

-

TOPB001 Belt Bottom-Entry Mixer

TOPB001 Belt Bottom-Entry Mixer

Based on Top's years of experience and unique technology, advanced measurement and analysis technology are applied. Design an efficient impeller with a good mixing effect and use it on our DR mixer

● Top belt transmission mixer can provide bottom-in mixing from 0.37KW to 200KW, so all products have been strictly inspected by Top Engineers to ensure the high reliability of the products.

● Compact mechanical structure, reliable operation and smooth operation, easy to operate, maintain, and repair, - Everything is for the user's consideration

● The original impeller form increases the discharge volume significantly.

● A variety of shaft seal types meet different materials and working conditions

● First motor fixation reduces vibration significantly.

● Filling seal or mechanical seal can be selected according to process requirements.

● Deep groove ball bearing system ensures long-term use without lubrication

Explore More

-

TOPB002 TDC Series Magnetic Bottom-Entry Mixer

TOPB002 TDC Series Magnetic Bottom-Entry Mixer

● According to Top's years of experience and unique technology, advanced measurement and analysis technology are applied. Design an efficient impeller with a good mixing effect and use it on our DR mixer.

● Top DK mixer can provide bottom-in mixing from 0.37KW to 200KW. All products are strictly tested by Top Engineers to ensure the high reliability of the product.

● Compact mechanical structure, reliable and stable operation, easy to operate, maintain, and repair, everything is for the user's consideration.

● The original impeller form increases the discharge volume significantly.

● A variety of shaft seal types meet different materials and working conditions.

● First motor fixation reduces vibration significantly.

● Filling seal or mechanical seal can be selected according to process requirements.

● Deep groove ball bearing system ensures long-term use without lubrication.

Explore More

-

TOPB003 PS Series Bottom-Entry Crusher And Mixer

TOPB003 PS Series Bottom-Entry Crusher And Mixer

● According to Top's years of experience and unique technology, advanced measurement and analysis technology are applied. Design an efficient impeller with an good mixing effect and use it on our DR mixer.

● Top belt transmission mixer can provide bottom-in mixing from 0.37KW to 200KW. All products are strictly tested by Top Engineers to ensure the high reliability of the product.

● Compact mechanical structure, reliable operation and smooth operation, easy to operate, maintain, and repair, - Everything is for the user's consideration.

● The original impeller form increases the discharge volume significantly.

● A variety of shaft seal types meet different materials and working conditions.

● First motor fixation reduces vibration significantly.

● Filling seal or mechanical seal can be selected according to process requirements.

● Deep groove ball bearing system ensures long-term use without lubrication.

Explore More

-

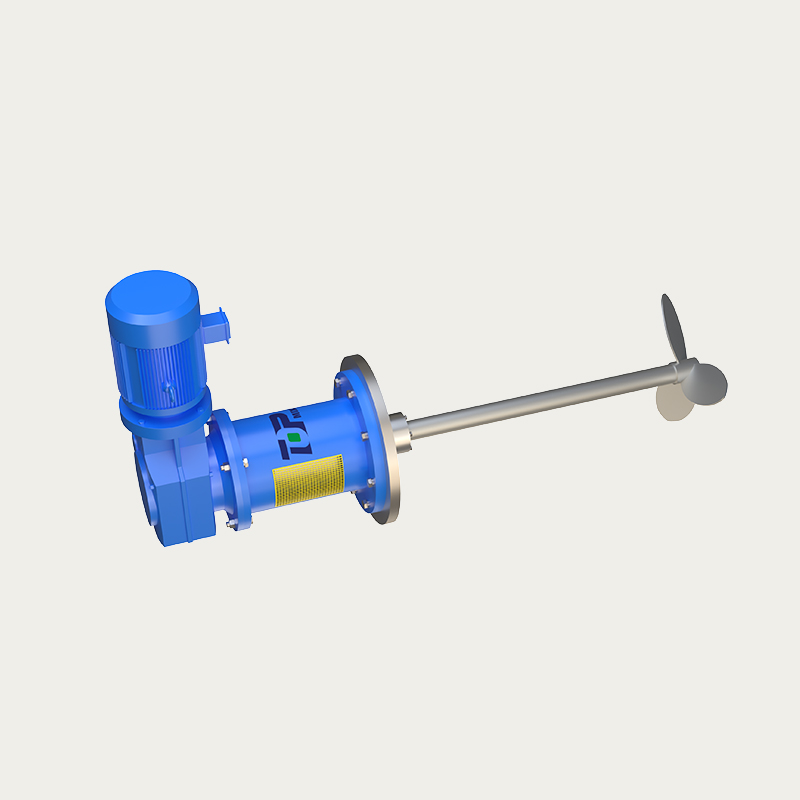

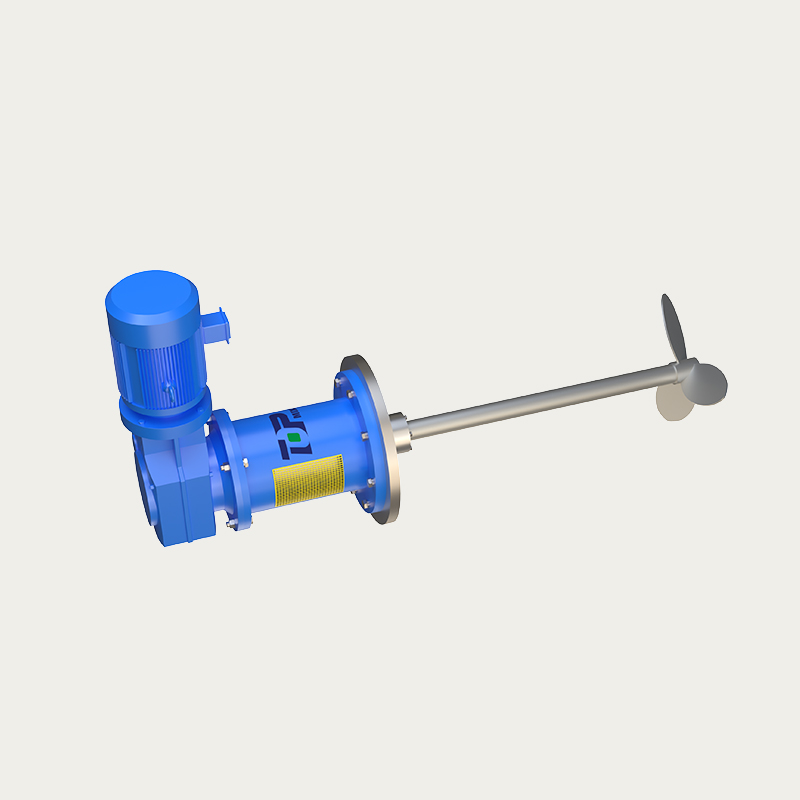

TOPC001 CMC Series Magnetic Side-Entry Mixer

TOPC001 CMC Series Magnetic Side-Entry Mixer

This series of mixers adopts an isolation sleeve static sealing structure and uses a strong magnetic field to transmit torque without contact, which can achieve permanent zero leakage. It is usually used in flammable, explosive, high-pressure, toxic media and other occasions.

Advantages: The high mixing effect that a side-in mixer can achieve when power consumption is consumed, the power is only 1/3-2/3 of that of a general center mixer.

Note: When selecting a model, users need to provide whether they contain solid particles and corrosive media.

Explore More

English

English