-

TOPH41 Series U-Shaped Ribbon Mixer

TOPH41 Series U-Shaped Ribbon Mixer

The working volume of the screw mixer is from 0.014m3-14.5m3. The different power and speeds meet more requirements. Its characteristic is that the equipment can be coordinated well with your machine. It has a vacuum and hot and cold jackets. The materials can be selected at any time. The intermediate or bottom discharge design is available. The cutter and a variety of filler boxes are available. Plus its unique four optional screw arrangement forms make the materials evenly mixed.

Explore More

-

TOPH42 Series US Twin Screw Mixer

TOPH42 Series US Twin Screw Mixer

The 42 series US double screw mixer is manufactured and produced directly using American technology. Based on the data provided by users and the data collected in the experiment, American engineering, and technicians have developed this effective equipment to meet the different needs of users. Excellent production technology and high-quality materials ensure the long service life, and safe and reliable characteristics of the equipment. It is suitable for material mixing in different industries and is widely used in pharmaceuticals, food, fine chemicals, petrochemicals, pesticides, coatings, cosmetics, plastics, pigments, fees, and other industries.

Explore More

-

TOPH51 Series FL High Speed Disperser

TOPH51 Series FL High Speed Disperser

This series of dispersion mixers can be equipped with a toothed dispersion tray for high-speed dispersion stirring, or various types of stirring machines for stirring on various occasions. This series of mixers is usually used to stir, dissolve, and disperse liquid and liquid solid-phase materials in the chemical industry such as coatings, dyes, pigments, and adhesives.

Explore More

-

TOPH52 Series SD Three-Axis Single Column Mixer

TOPH52 Series SD Three-Axis Single Column Mixer

The three-axle multi-function single-column strong dispersion and mixing mixer is a product with strong dispersion and mixing functions developed on the basis of a hydraulic lifting single-axle mixer. The conventional form is a high-speed dispersion mixer combined with anchor-type wall-scraping stirring, which has an extremely strong shearing effect and extremely high mixing efficiency. The product is very adaptable to medium-high viscosity and thixotropic materials; one of the sets of high-speed dispersers can replace medium-speed stirring, and the mixing methods are optional, such as screws, blades, frames, etc., and the good stirring form can be designed according to the characteristics of the material and production process.

Explore More

-

TOPH52 Series SH Three-Shaft Double-Column Mixer

TOPH52 Series SH Three-Shaft Double-Column Mixer

The three-axle multi-function dual-column strong dispersion and mixing mixer is a product with strong dispersion and mixing functions developed on the basis of a hydraulic lifting single-axle mixer. The conventional form is a high-speed dispersion mixer combined with anchor-type wall scraping stirring, which has an extremely strong shearing effect and extremely high mixing efficiency. The product is very adaptable to medium-high viscosity and thixotropic materials; one of the sets of high-speed dispersers can replace medium-speed mixers, and the mixing methods are optional, such as screws, blades, frames, etc., and the good mixing form can be designed according to the characteristics of the material and production process.

Explore More

-

TOPH53 Series SY Two-Speed Hydraulic Mixer

TOPH53 Series SY Two-Speed Hydraulic Mixer

The dual-speed multi-functional powerful dispersion mixer is a product with strong dispersion and stirring functions developed on the basis of a hydraulic lifting single-axis mixer. It has a concentric double-axis design; it has an extremely strong shearing effect and extremely high mixing efficiency; this product has good adaptability to medium and high viscosity and thixotropic materials, and a variety of stirring methods are available. Conventional such as anchor type, butterfly type, spiral type, frame type, etc., dispersion emulsification and stirring can be carried out simultaneously, driving the three-dimensional movement of edge materials and accelerating mixing. Wall scraping devices can also be installed to prevent the materials from sticking to the wall, which is highly adaptable and can be customized according to the characteristics of customers' materials and production process requirements.

Explore More

-

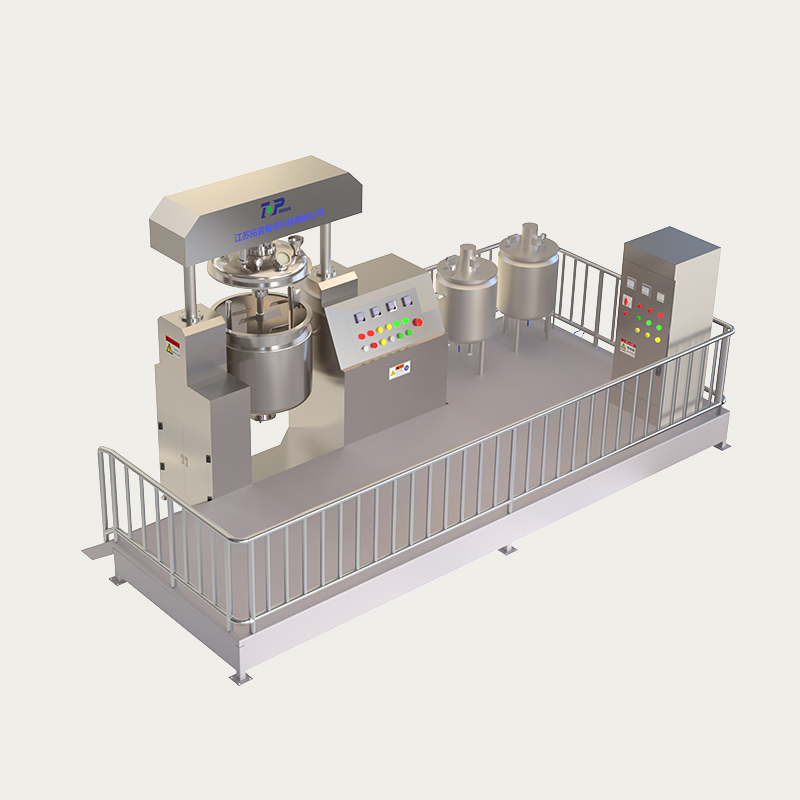

TOPH61 Series ZJH Homogenizer

TOPH61 Series ZJH Homogenizer

ZJH homogenous mixer is a patented product developed by our company in combination with advanced foreign technologies and is complementary to the RHⅡ homogenous mixer. Suitable for the production of high-viscosity materials such as foundation, cream, and toothpaste. Its biggest feature is that the internal and external circulation homogenizer can enable the material to work in the internal and external circulation homogenization state so that the material can achieve a good emulsification effect.

This homogenous mixer is professionally designed according to the paste-making process of cosmetics and ointments. This unit consists of a pretreatment pot, vacuum emulsification mixing pot, vacuum pump, hydraulic system, material pouring system, electrical control system, working platform, and other parts. This unit is simple to operate, has stable performance, good homogeneous performance, high production efficiency, convenient cleaning, reasonable structure, small footprint, and high automation.

Explore More

-

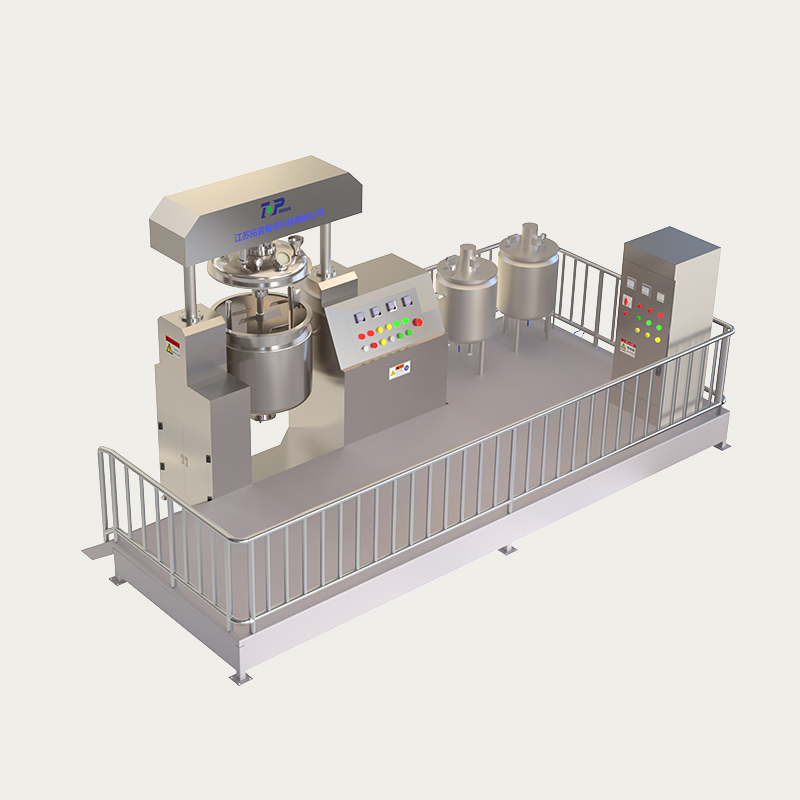

TOP62 Series DJH Homogenizer

TOP62 Series DJH Homogenizer

62 series DJH homogenous mixer is a product developed by our company in combination with advanced foreign technologies. It is suitable for the production of high-viscosity materials such as foundation, cream, and toothpaste. Its biggest feature is that the internal and external circulation homogenizer can enable the material to work in the internal and external circulation homogenization state so that the material can achieve a good emulsification effect.

This homogeneous emulsion mixer is professionally designed according to the paste-making process of cosmetics and ointments. This unit consists of a pretreatment pot, vacuum emulsification mixing pot, vacuum pump, hydraulic system, material pouring system, electrical control system, working platform, and other parts. This unit is easy to operate, has stable performance, good homogeneous performance, high production efficiency, reasonable cleaning, small structure, low floor area, and a high degree of automation.

Explore More

English

English