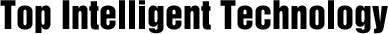

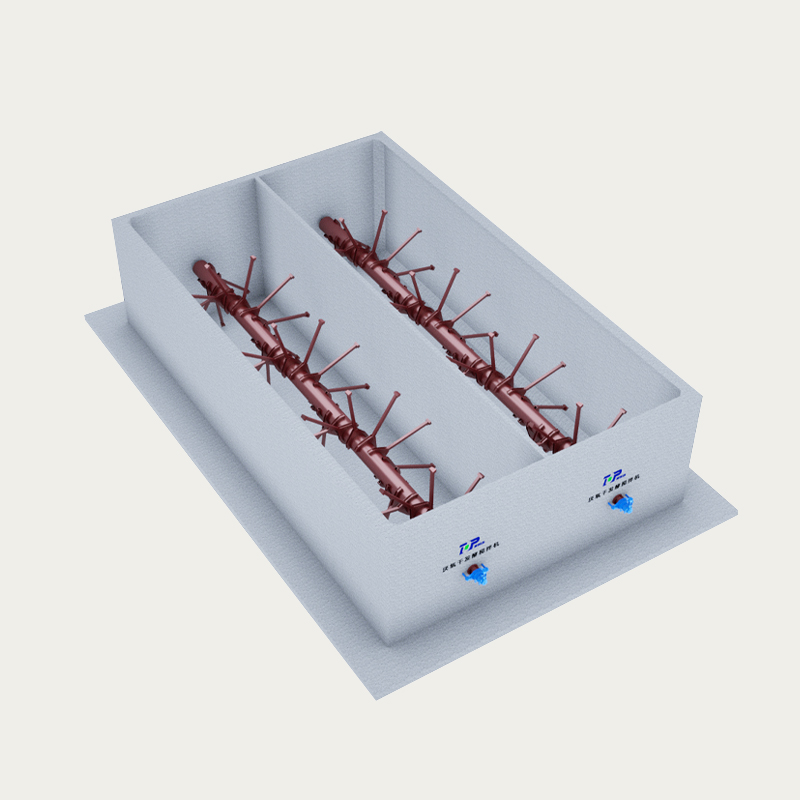

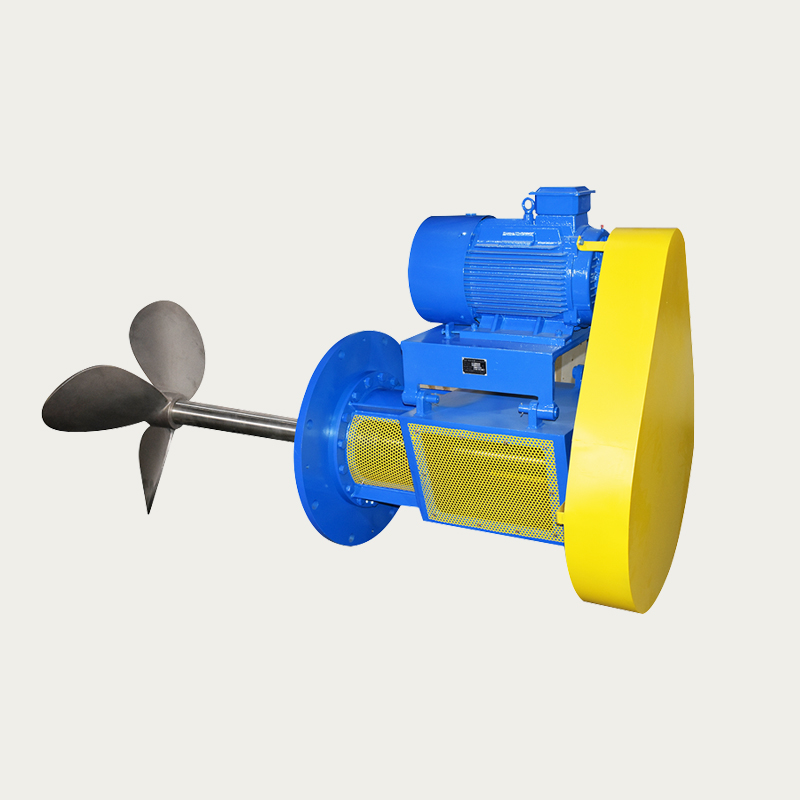

Environmentally Friendly Anaerobic Series

Environmentally Friendly Anaerobic Series is a set of advanced wastewater treatment systems designed to degrade organic pollutants in an environmentally sustainable manner. These systems use anaerobic bacteria to break down organic matter in the absence of oxygen, producing biogas as a byproduct, which can be used as a renewable energy source. The anaerobic process is highly efficient in treating high-strength industrial effluents, such as those from food processing, breweries, pharmaceuticals, and petrochemicals. It offers advantages like lower energy consumption, reduced sludge production, and minimal chemical usage compared to traditional aerobic treatment methods. These systems are ideal for industries aiming to minimize their environmental footprint, reduce operational costs, and recover valuable resources, contributing to a more sustainable and eco-friendly wastewater treatment approach.

English

English