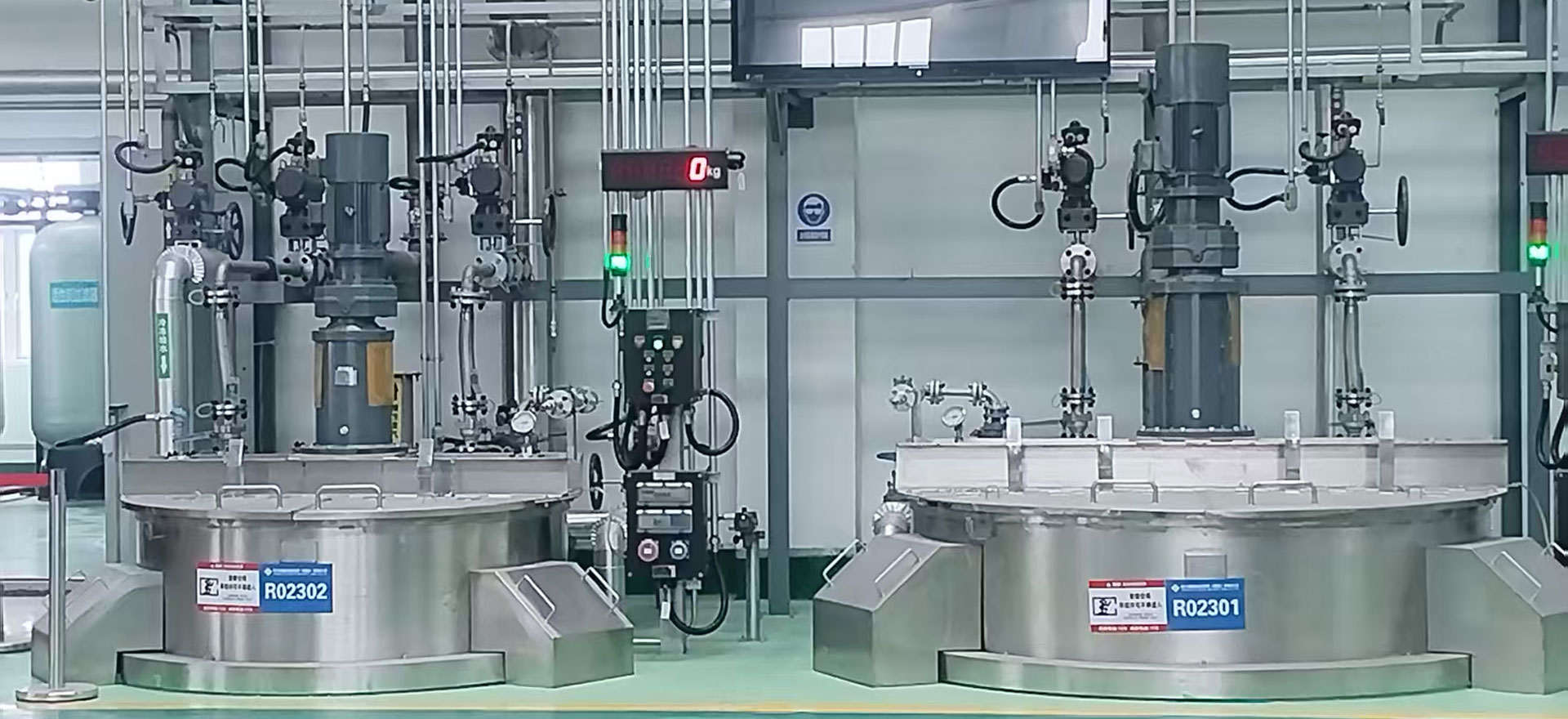

Wuxi Top Mixing Equipment Co., Ltd. has been deeply engaged in the mixing process of the chemical industry for 20 years. Relying on the professional technical team of the fine chemical mixing division, it provides customized mixing system solutions for global chemical companies. The company focuses on the research and development of high-precision and high-stability mixing equipment, which can meet stringent process requirements such as basic chemical raw material synthesis, polymer material polymerization, and catalyst suspension and dispersion.

Core technologies and advantages

• Corrosion-resistant design: Hastelloy, titanium, and special lining materials are used to adapt to highly corrosive media environments such as strong acids, strong alkalis, and organic solvents

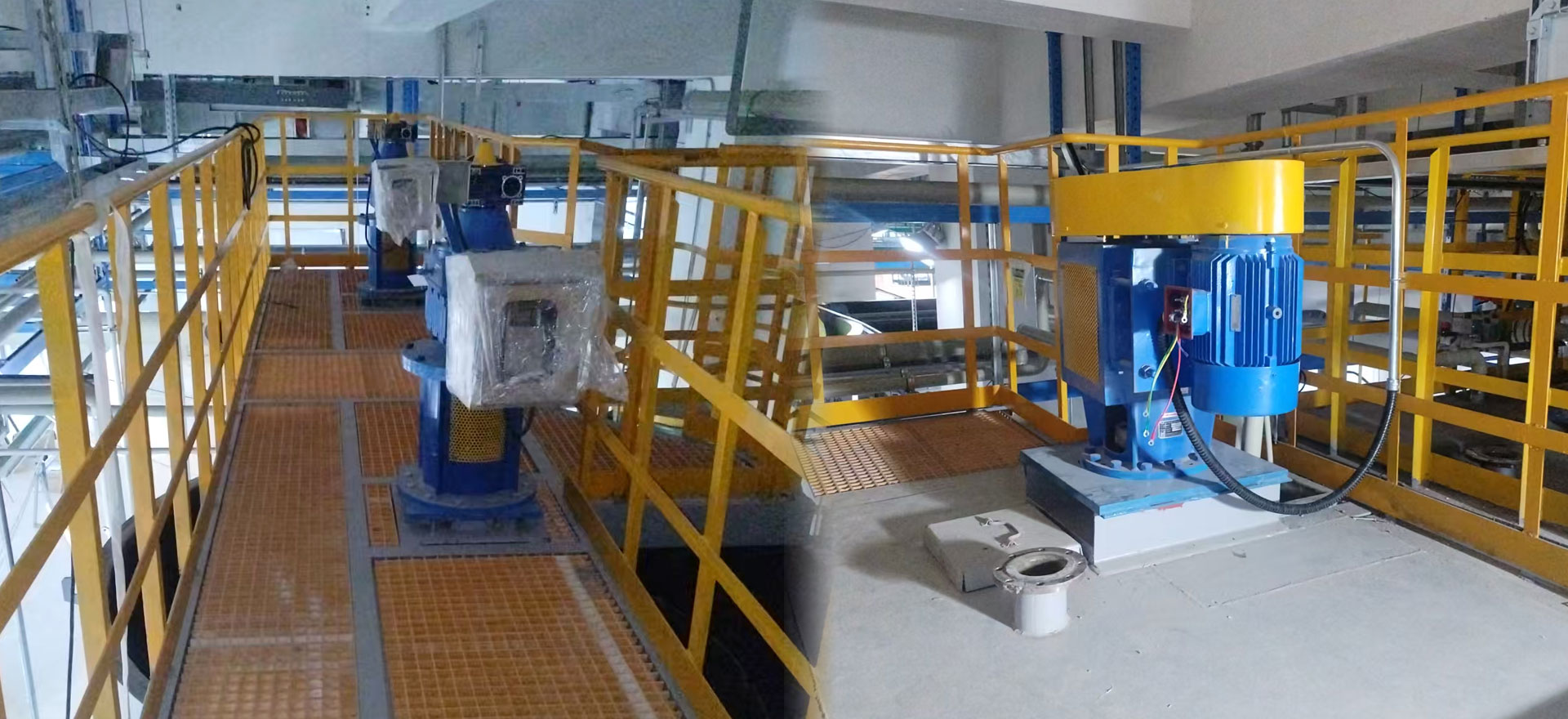

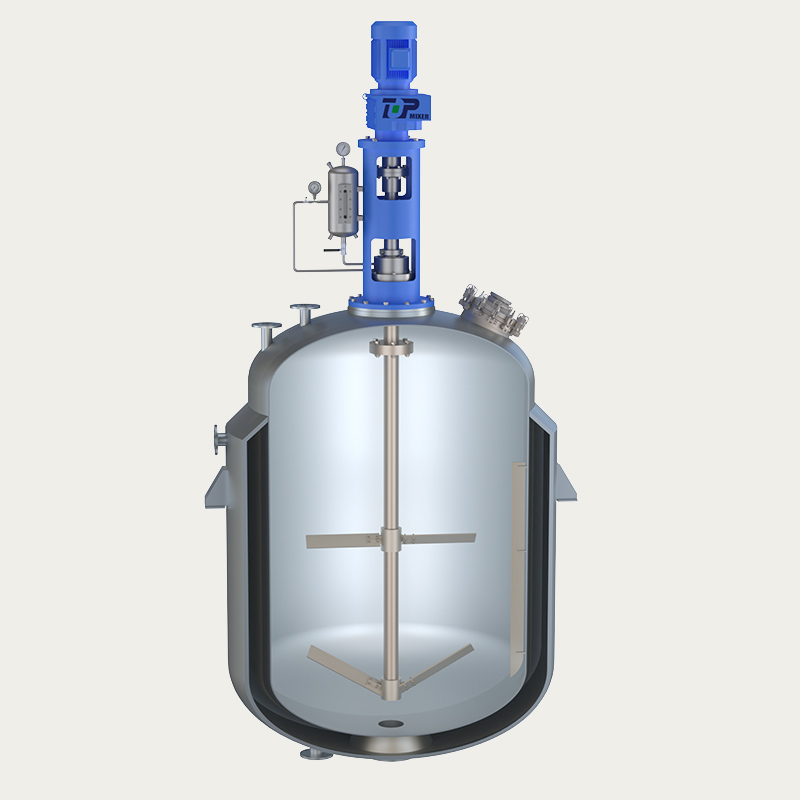

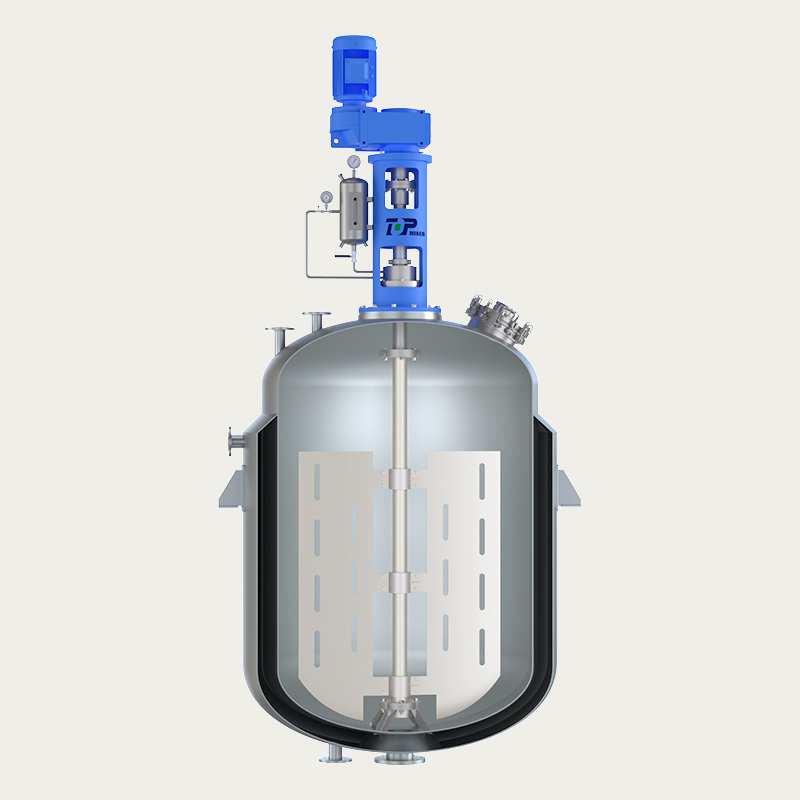

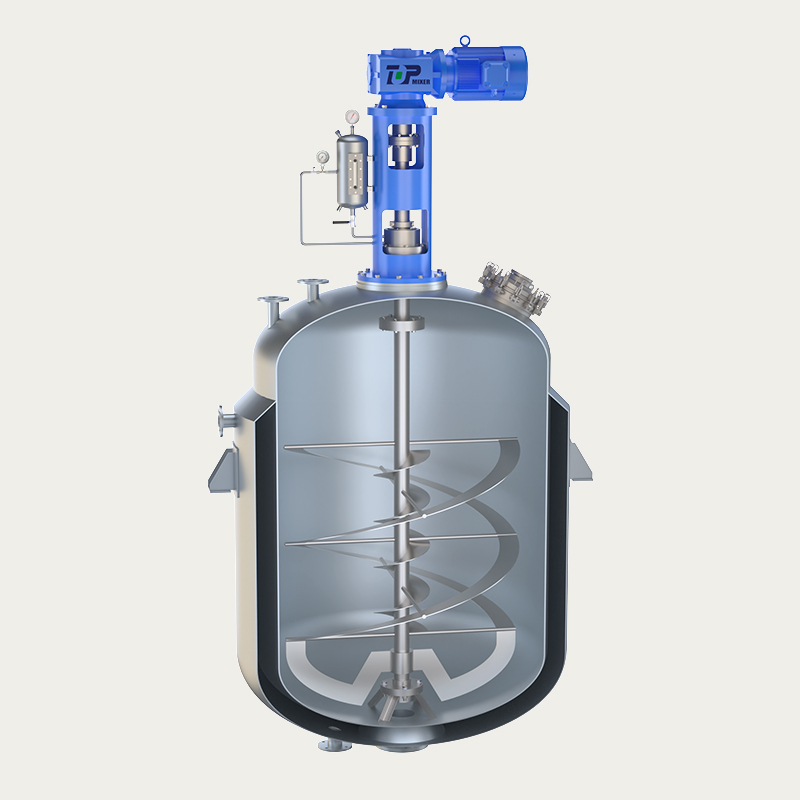

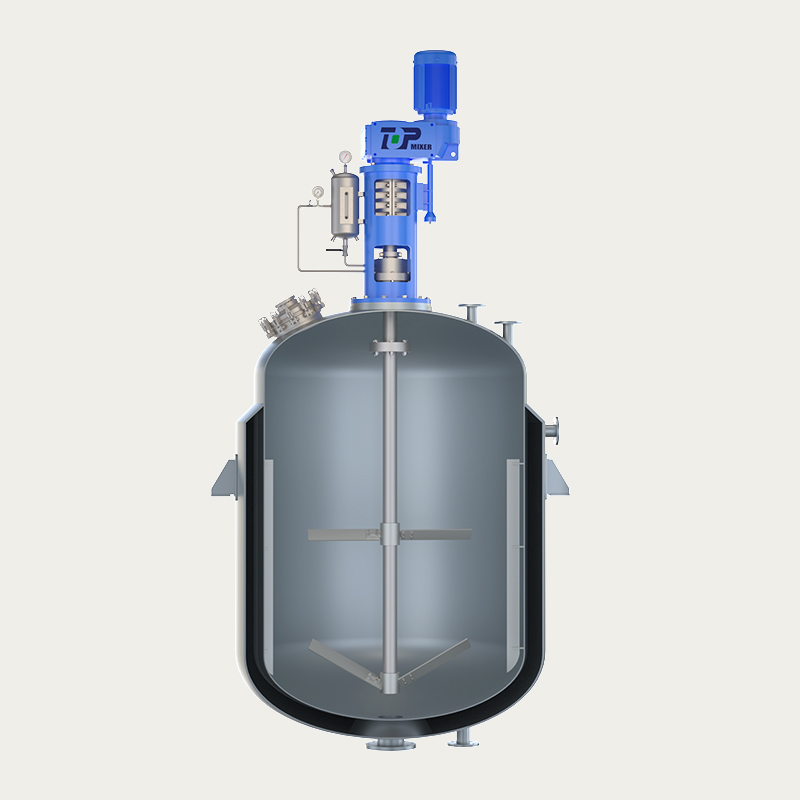

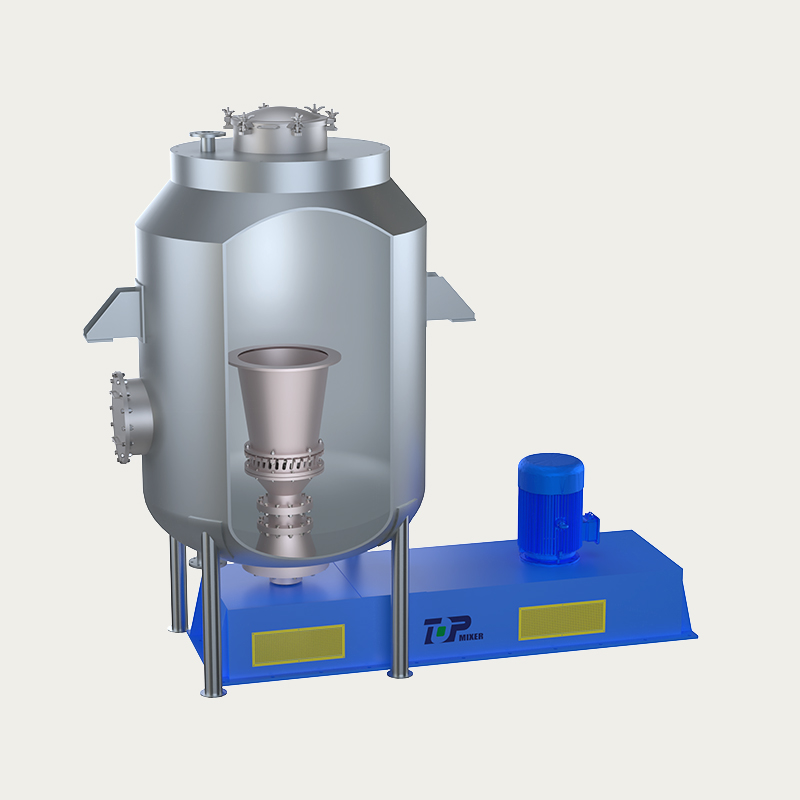

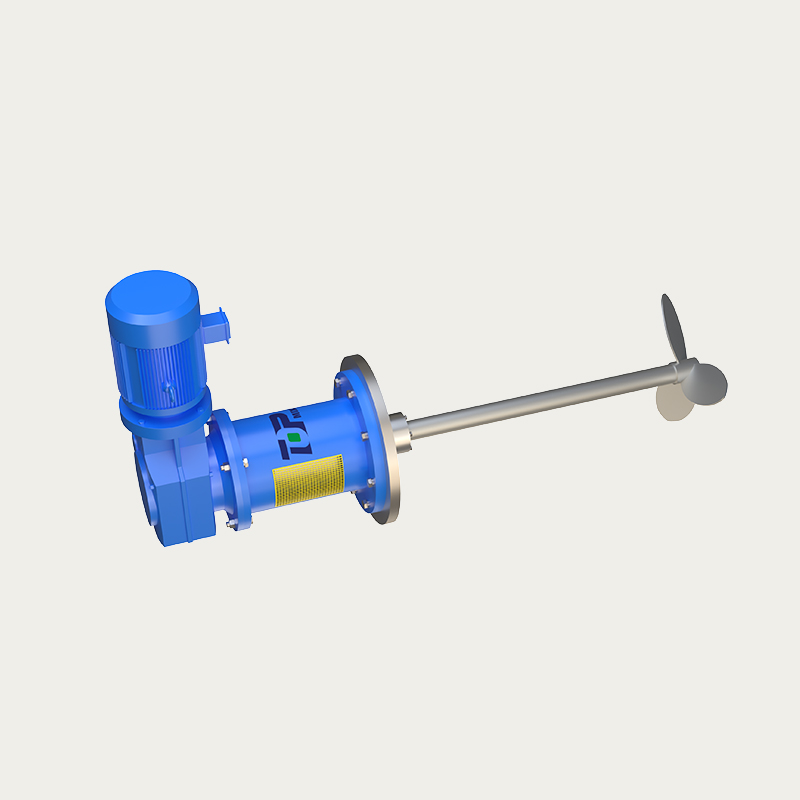

• Process adaptability: Customizable mixing systems for reactors, crystallizers, dissolution tank,s and other equipment can be developed, covering the viscosity range below 5,000 cPs

• Process control optimization: Integrated frequency conversion speed regulation, temperature interlock, and DCS interface functions to meet the process stability required by API/EN standards

• Safety compliance: The equipment design complies with ASME BPE and ATEX explosion-proof standards, and supports the CIP/SIP cleaning and sterilization process required by GMP

Typical application scenarios

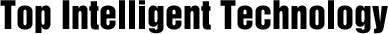

Petrochemical: catalytic cracking slurry homogenization, residual oil desulfurization reaction system

Fine chemicals: nanomaterial dispersion, pharmaceutical intermediate synthesis

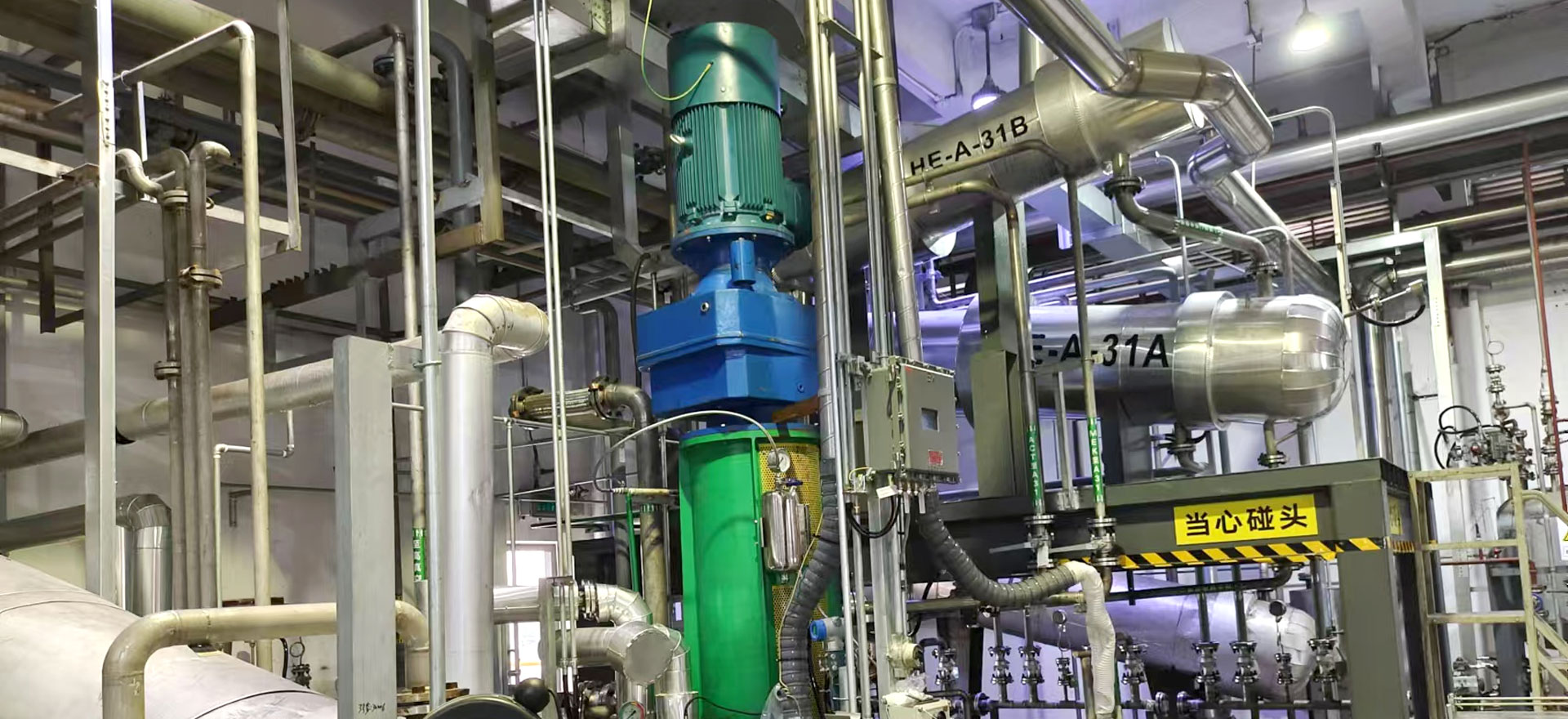

New materials: lithium battery slurry preparation, polymer synthesis

Industrial coatings: pigment pre-dispersion, resin curing reaction control

Relying on ISO With 5S manufacturing standards and modular design concepts certified by the 9001 system, Top Equipment has been successfully applied to continuous production projects of global chemical companies such as Dow Chemical and Asahi Kasei. The technical service teams stationed in the United States, Europe, and Southeast Asia can provide customers with full-process technical support from laboratory trials to industrial scale-up, helping to achieve the dual goals of improving process efficiency and optimizing energy consumption.

English

English