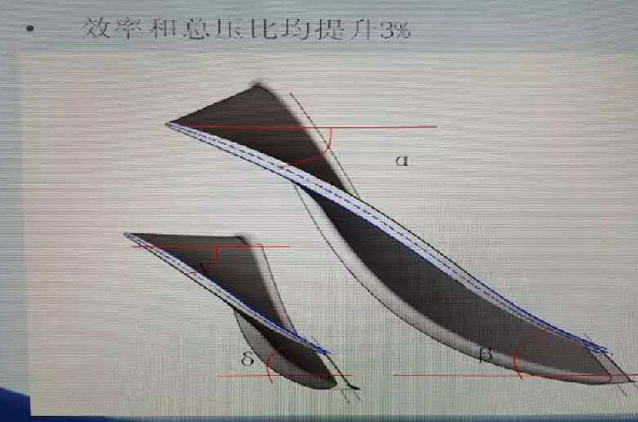

The impeller can be optimized using CFD to effectively meet process requirements with a smaller power input.

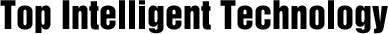

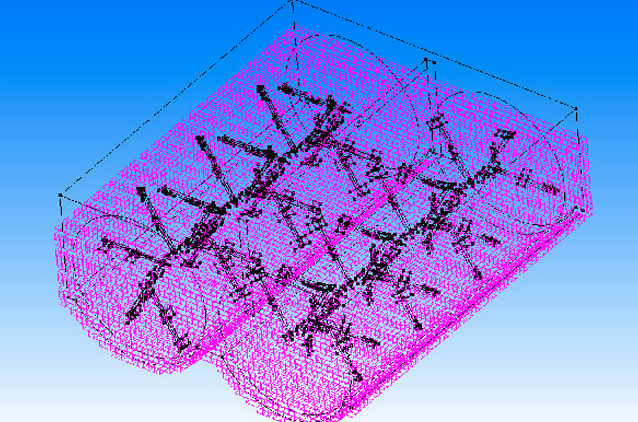

First, the overall flow field and local velocities must be determined. This involves avoiding areas of low mixing intensity and the locations of feed devices or heat exchangers. The hydraulic loads on these components will be derived from CFD, which serves as input for finite element analysis (FEA) in its design. CFD post-processing tools are well-suited for visualizing actual process conditions.

Knowledge of turbulence intensity is fundamental to the design of many agitated processes. The dispersion of gas or liquid or the stress on sensitive crystals is determined by turbulence parameters. CFD provides the local distribution of these parameters, allowing for comparisons of process results across different impeller types. Even with very complex geometries, heat transfer coefficients on coils, tube bundles, or plates can be calculated in this way.

The mixing process in a stirred tank (continuous or batch operation) allows for the tracking of concentration and temperature profiles. This not only enables the detection and avoidance of dead zones, but also allows for the design of reactors, crystallizers, or fermenters.

English

English