-

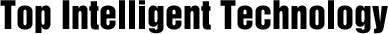

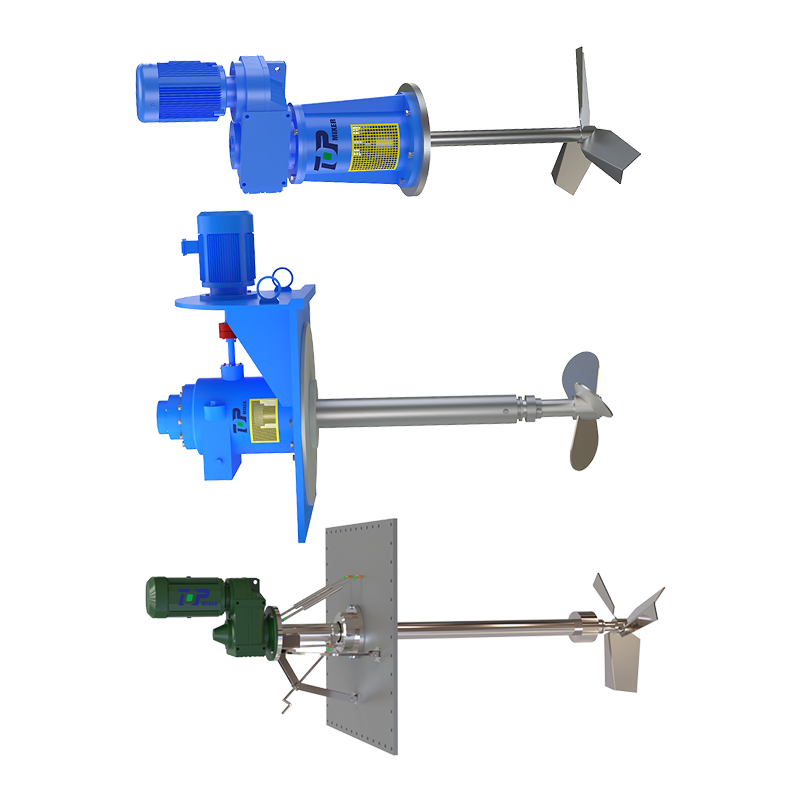

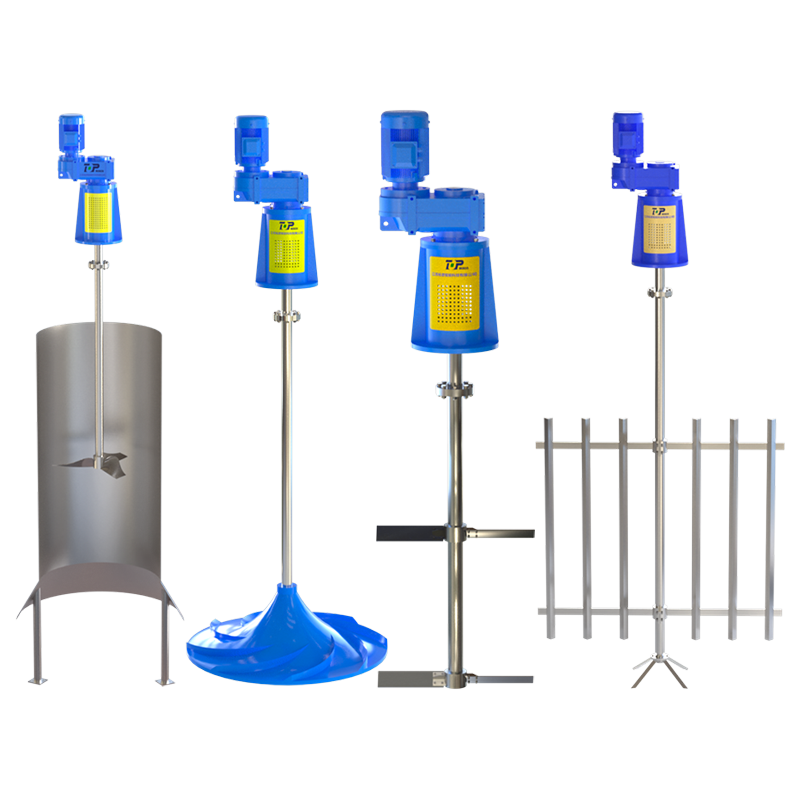

A top-entry mixer is a versatile industrial mixing device mounted vertically on top of a tank or vessel. Its key characteristics include robust construction, high torque capabilities, and customizable impellers to suit various mixing needs. Designed for efficient blending, agitation, or homogenization, it accommodates a wide range of viscosities, from thin liquids to thick slurries. Top-entry mixers are commonly used in industries such as chemical processing, pharmaceuticals, food and beverage, and wastewater treatment. They are ideal for mixing large volumes, heat transfer, or dissolving solids into liquids. With options for variable speed control and seal configurations, these mixers ensure performance, scalability, and reliability in demanding industrial applications.Explore More

A top-entry mixer is a versatile industrial mixing device mounted vertically on top of a tank or vessel. Its key characteristics include robust construction, high torque capabilities, and customizable impellers to suit various mixing needs. Designed for efficient blending, agitation, or homogenization, it accommodates a wide range of viscosities, from thin liquids to thick slurries. Top-entry mixers are commonly used in industries such as chemical processing, pharmaceuticals, food and beverage, and wastewater treatment. They are ideal for mixing large volumes, heat transfer, or dissolving solids into liquids. With options for variable speed control and seal configurations, these mixers ensure performance, scalability, and reliability in demanding industrial applications.Explore More

-

A bottom-entry mixer is an industrial mixing device installed at the bottom of a tank or vessel and designed for efficient and localized agitation. Its compact design and direct-drive motor provide high energy efficiency and effective mixing with minimal maintenance. Key characteristics include a low-shear mixing mechanism, making it ideal for delicate processes, and ease of cleaning, often meeting stringent sanitary standards for industries like pharmaceuticals and food production. Bottom-entry mixers excel in applications requiring gentle blending, homogenization, or the prevention of sedimentation in low to medium-viscosity liquids. They are widely used in dairy processing, cosmetics, and biotechnology. Their design also supports processes where top-entry access is impractical, offering enhanced flexibility and compatibility with closed-system operations.Explore More

A bottom-entry mixer is an industrial mixing device installed at the bottom of a tank or vessel and designed for efficient and localized agitation. Its compact design and direct-drive motor provide high energy efficiency and effective mixing with minimal maintenance. Key characteristics include a low-shear mixing mechanism, making it ideal for delicate processes, and ease of cleaning, often meeting stringent sanitary standards for industries like pharmaceuticals and food production. Bottom-entry mixers excel in applications requiring gentle blending, homogenization, or the prevention of sedimentation in low to medium-viscosity liquids. They are widely used in dairy processing, cosmetics, and biotechnology. Their design also supports processes where top-entry access is impractical, offering enhanced flexibility and compatibility with closed-system operations.Explore More

-

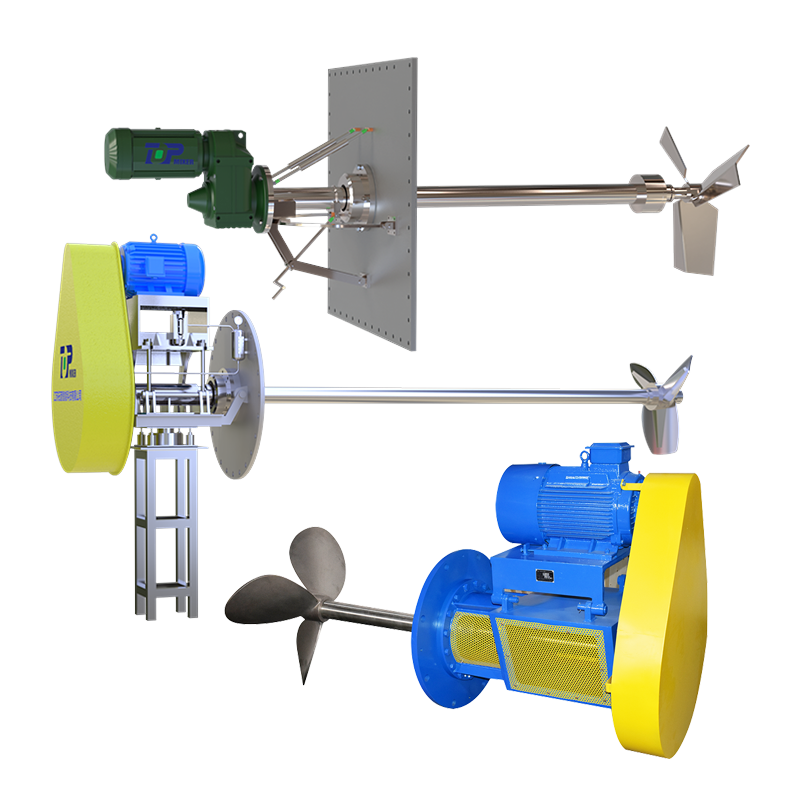

Side-entry mixer is an industrial mixer installed on the sidewall of a tank or vessel, designed for efficient mixing of large volumes or maintaining continuous motion in stored liquids. Its compact design minimizes energy consumption while providing robust agitation. Key characteristics include angled mounting for flow patterns, high efficiency in preventing sediment buildup, and ease of maintenance due to external motor positioning. Side-entry mixers are ideal for blending, homogenization, and maintaining uniform temperature in applications such as oil storage tanks, wastewater treatment, and chemical processing. They are particularly suited for mixing low- to medium-viscosity liquids in large tanks where top-entry or bottom-entry mixers are impractical, ensuring cost-effective and reliable performance in demanding industrial environments.Explore More

Side-entry mixer is an industrial mixer installed on the sidewall of a tank or vessel, designed for efficient mixing of large volumes or maintaining continuous motion in stored liquids. Its compact design minimizes energy consumption while providing robust agitation. Key characteristics include angled mounting for flow patterns, high efficiency in preventing sediment buildup, and ease of maintenance due to external motor positioning. Side-entry mixers are ideal for blending, homogenization, and maintaining uniform temperature in applications such as oil storage tanks, wastewater treatment, and chemical processing. They are particularly suited for mixing low- to medium-viscosity liquids in large tanks where top-entry or bottom-entry mixers are impractical, ensuring cost-effective and reliable performance in demanding industrial environments.Explore More

-

A magnetic drive mixer is a sealed mixing device that uses magnetic coupling to transfer torque from the motor to the impeller, eliminating the need for mechanical seals. Its key characteristics include a hermetic seal, ensuring zero leakage and making it ideal for sterile or hazardous environments. This design enhances safety, minimizes contamination risks, and reduces maintenance needs. Magnetic drive mixers are highly efficient and compatible with a wide range of viscosities and temperatures. They are widely used in industries requiring strict sanitary or containment standards, such as pharmaceuticals, biotechnology, chemicals, and food processing. Their applications include blending, emulsification, and suspension in sensitive processes, particularly in closed systems where maintaining product integrity and cleanliness is critical.Explore More

A magnetic drive mixer is a sealed mixing device that uses magnetic coupling to transfer torque from the motor to the impeller, eliminating the need for mechanical seals. Its key characteristics include a hermetic seal, ensuring zero leakage and making it ideal for sterile or hazardous environments. This design enhances safety, minimizes contamination risks, and reduces maintenance needs. Magnetic drive mixers are highly efficient and compatible with a wide range of viscosities and temperatures. They are widely used in industries requiring strict sanitary or containment standards, such as pharmaceuticals, biotechnology, chemicals, and food processing. Their applications include blending, emulsification, and suspension in sensitive processes, particularly in closed systems where maintaining product integrity and cleanliness is critical.Explore More

-

Special mixer is a highly customized mixing solution designed to meet unique processing requirements in specialized industries. Its key characteristics include tailored impeller designs, variable speed controls, and the ability to handle viscosities, pressures, or temperatures. Special mixers are often engineered for complex tasks such as high-shear mixing, vacuum processing, or multi-phase blending. They are used in applications where standard mixers may fall short, such as in the production of adhesives, sealants, polymers, or specialty chemicals. Other uses include precision blending in the pharmaceutical, cosmetic, and food industries. With advanced features like automated controls and integration with process systems, special mixers provide performance and efficiency for demanding and intricate industrial processes.Explore More

Special mixer is a highly customized mixing solution designed to meet unique processing requirements in specialized industries. Its key characteristics include tailored impeller designs, variable speed controls, and the ability to handle viscosities, pressures, or temperatures. Special mixers are often engineered for complex tasks such as high-shear mixing, vacuum processing, or multi-phase blending. They are used in applications where standard mixers may fall short, such as in the production of adhesives, sealants, polymers, or specialty chemicals. Other uses include precision blending in the pharmaceutical, cosmetic, and food industries. With advanced features like automated controls and integration with process systems, special mixers provide performance and efficiency for demanding and intricate industrial processes.Explore More

-

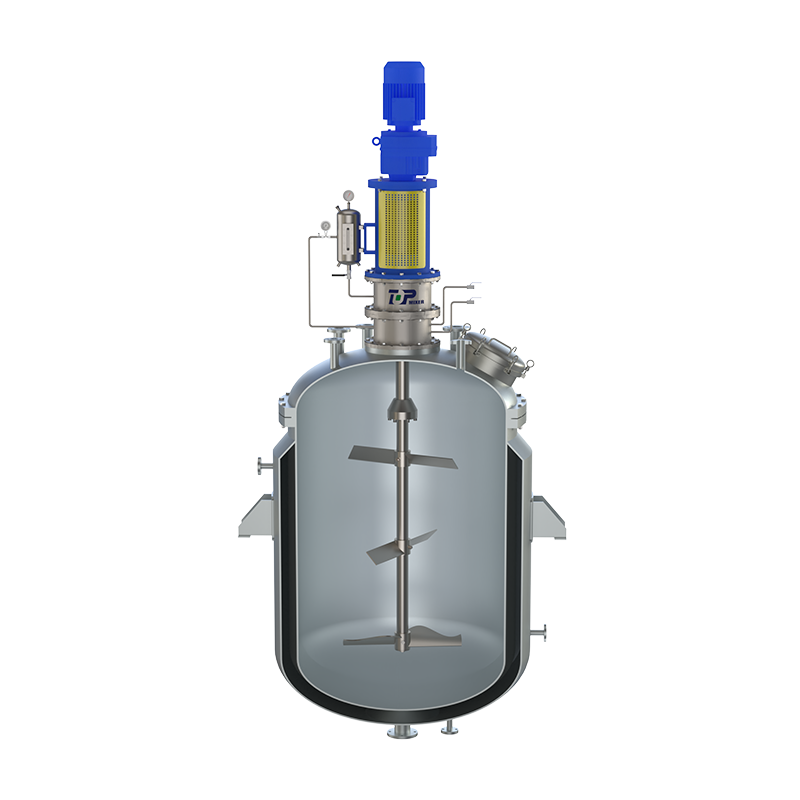

The specially customized agitator is a tailor-made mixing device designed to address specific process challenges in various industries. Its key characteristics include flexibility in design, such as custom impeller shapes, shaft lengths, and materials to suit unique requirements like high viscosity, abrasive media, or temperatures. These agitators can be adapted for low-shear or high-shear mixing, suspension, or heat transfer applications. They are widely used in industries such as pharmaceuticals, petrochemicals, food processing, and wastewater treatment. Customized agitators are ideal for processes requiring precise control, such as emulsification, crystallization, or gas dispersion. By meeting the exact needs of the application, these agitators ensure efficient operation, enhanced product quality, and compatibility with complex production systems.Explore More

The specially customized agitator is a tailor-made mixing device designed to address specific process challenges in various industries. Its key characteristics include flexibility in design, such as custom impeller shapes, shaft lengths, and materials to suit unique requirements like high viscosity, abrasive media, or temperatures. These agitators can be adapted for low-shear or high-shear mixing, suspension, or heat transfer applications. They are widely used in industries such as pharmaceuticals, petrochemicals, food processing, and wastewater treatment. Customized agitators are ideal for processes requiring precise control, such as emulsification, crystallization, or gas dispersion. By meeting the exact needs of the application, these agitators ensure efficient operation, enhanced product quality, and compatibility with complex production systems.Explore More

-

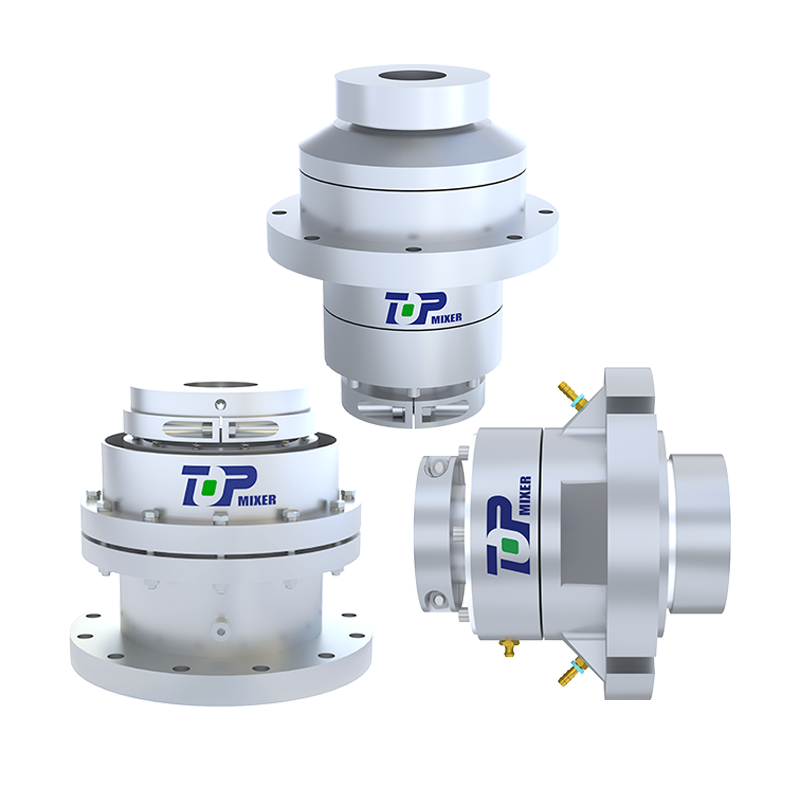

A mechanical seal is a device used to prevent leakage between a rotating shaft and a stationary housing in various machinery. It operates by using a combination of stationary and rotating components, often including a sealing face, spring, and secondary seals, to maintain a tight seal under varying pressures, temperatures, and speeds. Mechanical seals are highly reliable, reduce maintenance needs, and minimize fluid loss, making them essential in modern industries. Commonly used in pumps, mixers, compressors, and agitators, they are widely applied in sectors like oil and gas, chemical processing, water treatment, and power generation. Their ability to handle corrosive, high-temperature, or abrasive fluids ensures enhanced equipment performance and environmental protection, meeting stringent industrial standards.Explore More

A mechanical seal is a device used to prevent leakage between a rotating shaft and a stationary housing in various machinery. It operates by using a combination of stationary and rotating components, often including a sealing face, spring, and secondary seals, to maintain a tight seal under varying pressures, temperatures, and speeds. Mechanical seals are highly reliable, reduce maintenance needs, and minimize fluid loss, making them essential in modern industries. Commonly used in pumps, mixers, compressors, and agitators, they are widely applied in sectors like oil and gas, chemical processing, water treatment, and power generation. Their ability to handle corrosive, high-temperature, or abrasive fluids ensures enhanced equipment performance and environmental protection, meeting stringent industrial standards.Explore More

-

The Environmental Protection Water Treatment series comprises advanced systems designed to treat and purify water, ensuring it meets environmental and health standards. These systems utilize various technologies such as filtration, coagulation, flocculation, and chemical dosing to remove contaminants, sediments, and harmful microorganisms. They are highly efficient in treating both industrial and municipal wastewater, improving water quality while minimizing environmental impact. These water treatment solutions are essential for industries like pharmaceuticals, food processing, chemicals, and power generation, where maintaining clean water is crucial. The series is also widely used in municipal water treatment plants and for providing clean drinking water. Their adaptability, energy efficiency, and ability to treat a variety of pollutants make them vital for sustainable water management and environmental protection.Explore More

The Environmental Protection Water Treatment series comprises advanced systems designed to treat and purify water, ensuring it meets environmental and health standards. These systems utilize various technologies such as filtration, coagulation, flocculation, and chemical dosing to remove contaminants, sediments, and harmful microorganisms. They are highly efficient in treating both industrial and municipal wastewater, improving water quality while minimizing environmental impact. These water treatment solutions are essential for industries like pharmaceuticals, food processing, chemicals, and power generation, where maintaining clean water is crucial. The series is also widely used in municipal water treatment plants and for providing clean drinking water. Their adaptability, energy efficiency, and ability to treat a variety of pollutants make them vital for sustainable water management and environmental protection.Explore More

-

Environmentally Friendly Anaerobic Series is a set of advanced wastewater treatment systems designed to degrade organic pollutants in an environmentally sustainable manner. These systems use anaerobic bacteria to break down organic matter in the absence of oxygen, producing biogas as a byproduct, which can be used as a renewable energy source. The anaerobic process is highly efficient in treating high-strength industrial effluents, such as those from food processing, breweries, pharmaceuticals, and petrochemicals. It offers advantages like lower energy consumption, reduced sludge production, and minimal chemical usage compared to traditional aerobic treatment methods. These systems are ideal for industries aiming to minimize their environmental footprint, reduce operational costs, and recover valuable resources, contributing to a more sustainable and eco-friendly wastewater treatment approach.Explore More

Environmentally Friendly Anaerobic Series is a set of advanced wastewater treatment systems designed to degrade organic pollutants in an environmentally sustainable manner. These systems use anaerobic bacteria to break down organic matter in the absence of oxygen, producing biogas as a byproduct, which can be used as a renewable energy source. The anaerobic process is highly efficient in treating high-strength industrial effluents, such as those from food processing, breweries, pharmaceuticals, and petrochemicals. It offers advantages like lower energy consumption, reduced sludge production, and minimal chemical usage compared to traditional aerobic treatment methods. These systems are ideal for industries aiming to minimize their environmental footprint, reduce operational costs, and recover valuable resources, contributing to a more sustainable and eco-friendly wastewater treatment approach.Explore More

-

A mixing mixer is a versatile piece of equipment used to blend different substances to achieve a uniform consistency. It typically consists of a motorized rotor and blades or paddles, designed to rotate and combine materials such as liquids, powders, or pastes. Mixing mixers are highly adaptable, and capable of handling a wide range of materials across various industries, including food and beverage, chemicals, pharmaceuticals, and cosmetics. They come in various configurations, such as batch or continuous mixers, depending on the application requirements. Mixing mixers is essential for ensuring consistent product quality, reducing processing times, and improving efficiency. Their ability to handle complex formulations and their ease of cleaning make them indispensable in both small-scale and large-scale production environments.Explore More

A mixing mixer is a versatile piece of equipment used to blend different substances to achieve a uniform consistency. It typically consists of a motorized rotor and blades or paddles, designed to rotate and combine materials such as liquids, powders, or pastes. Mixing mixers are highly adaptable, and capable of handling a wide range of materials across various industries, including food and beverage, chemicals, pharmaceuticals, and cosmetics. They come in various configurations, such as batch or continuous mixers, depending on the application requirements. Mixing mixers is essential for ensuring consistent product quality, reducing processing times, and improving efficiency. Their ability to handle complex formulations and their ease of cleaning make them indispensable in both small-scale and large-scale production environments.Explore More

Home / Product

Wuxi Top Mixer – R&D, Manufacturing & One-Stop Service Center for Fluid/Powder/Slurry Mixing Equipment

Focuses on fluid, powder and slurry mixing equipment, providing high-quality, reliable products and one-stop services for integrated, automated

and intelligent complete sets of equipment.

English

English